Thread: 55 Wagon Progress

-

03-01-2016 08:04 PM #766

Worked on some louvers tonight, wanted to get some practice pieces done to see how well our "theory" might fare.

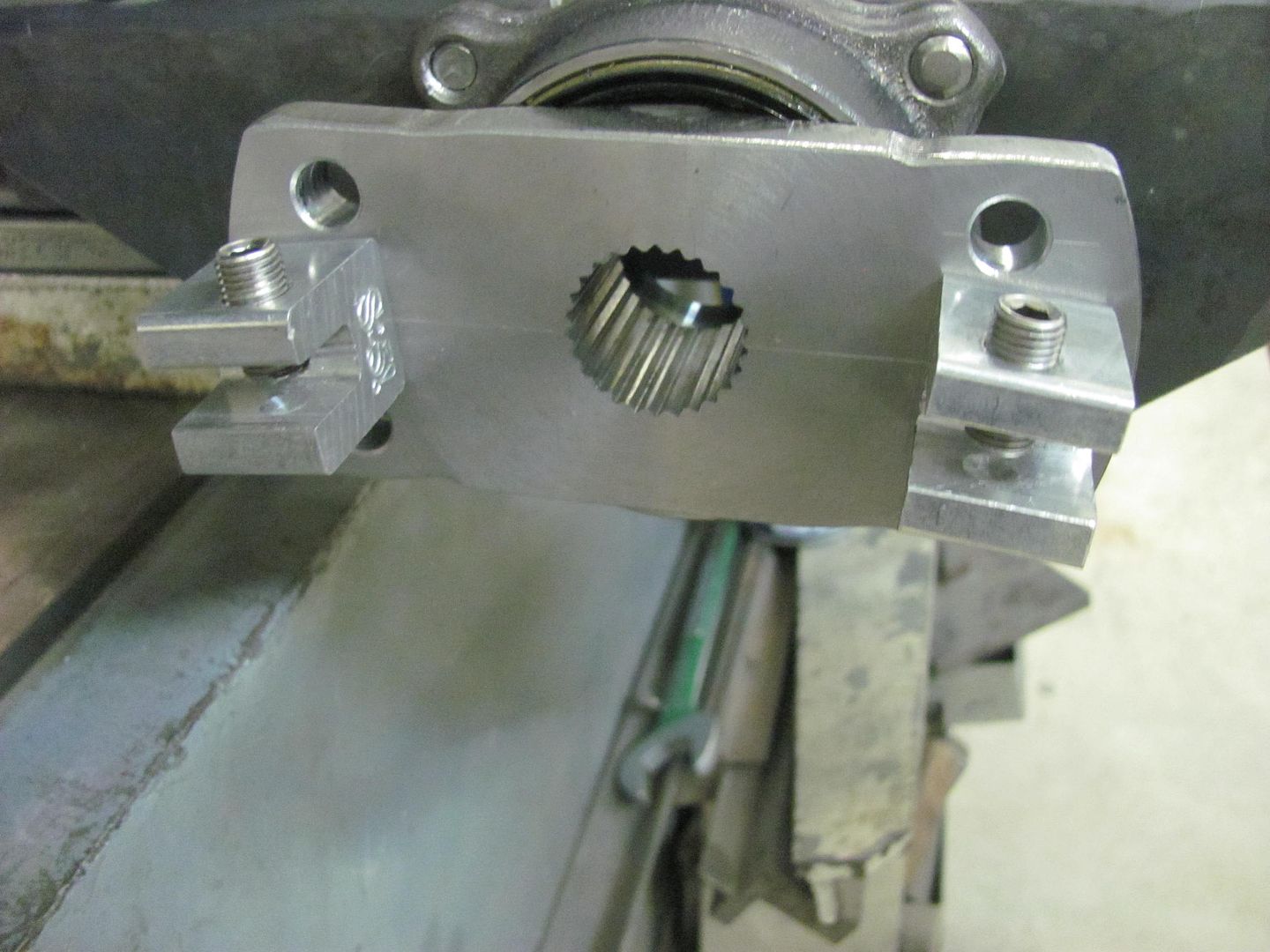

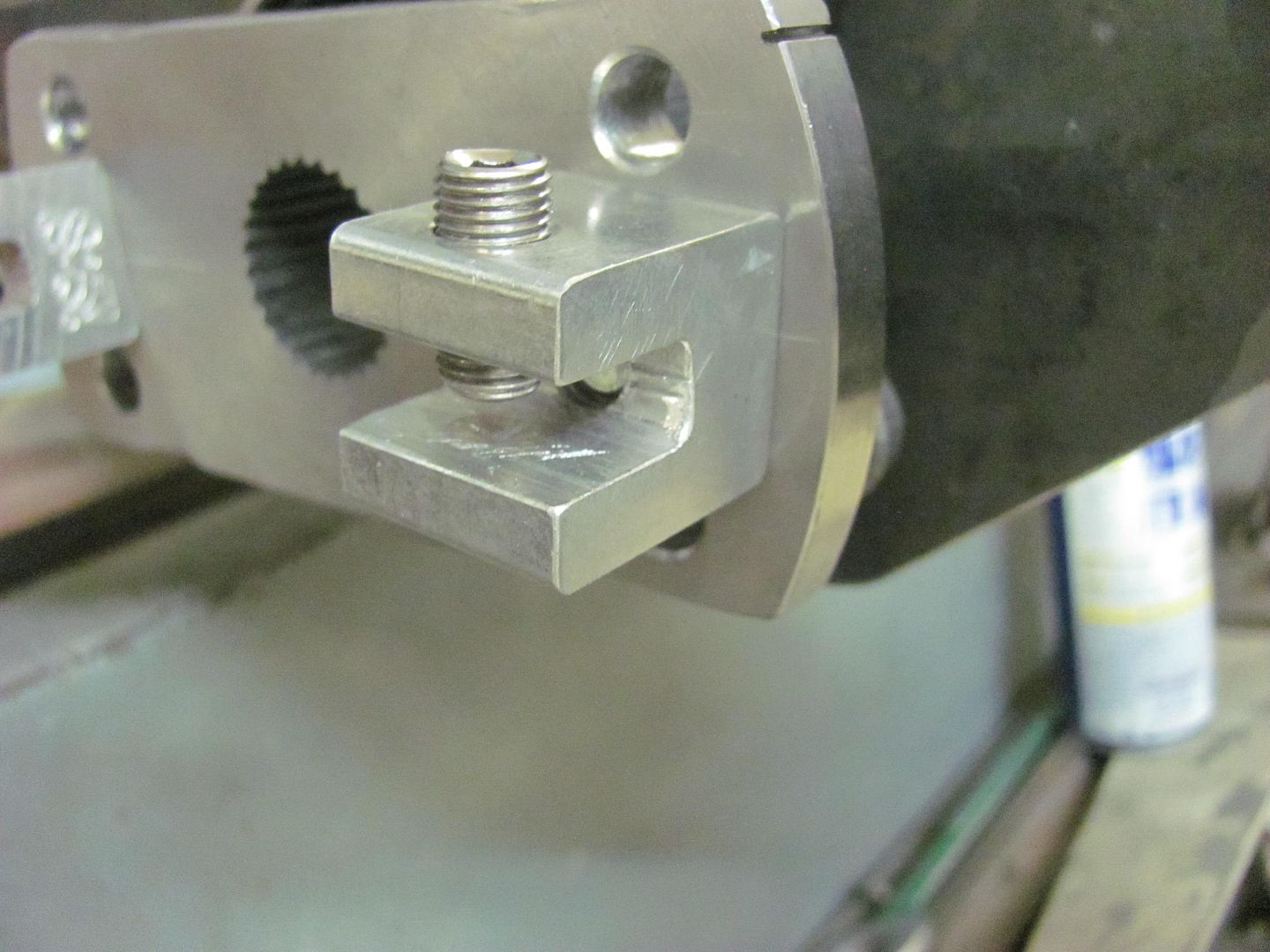

Kyle cutting an inside lip off the clamp before cutting it in half..

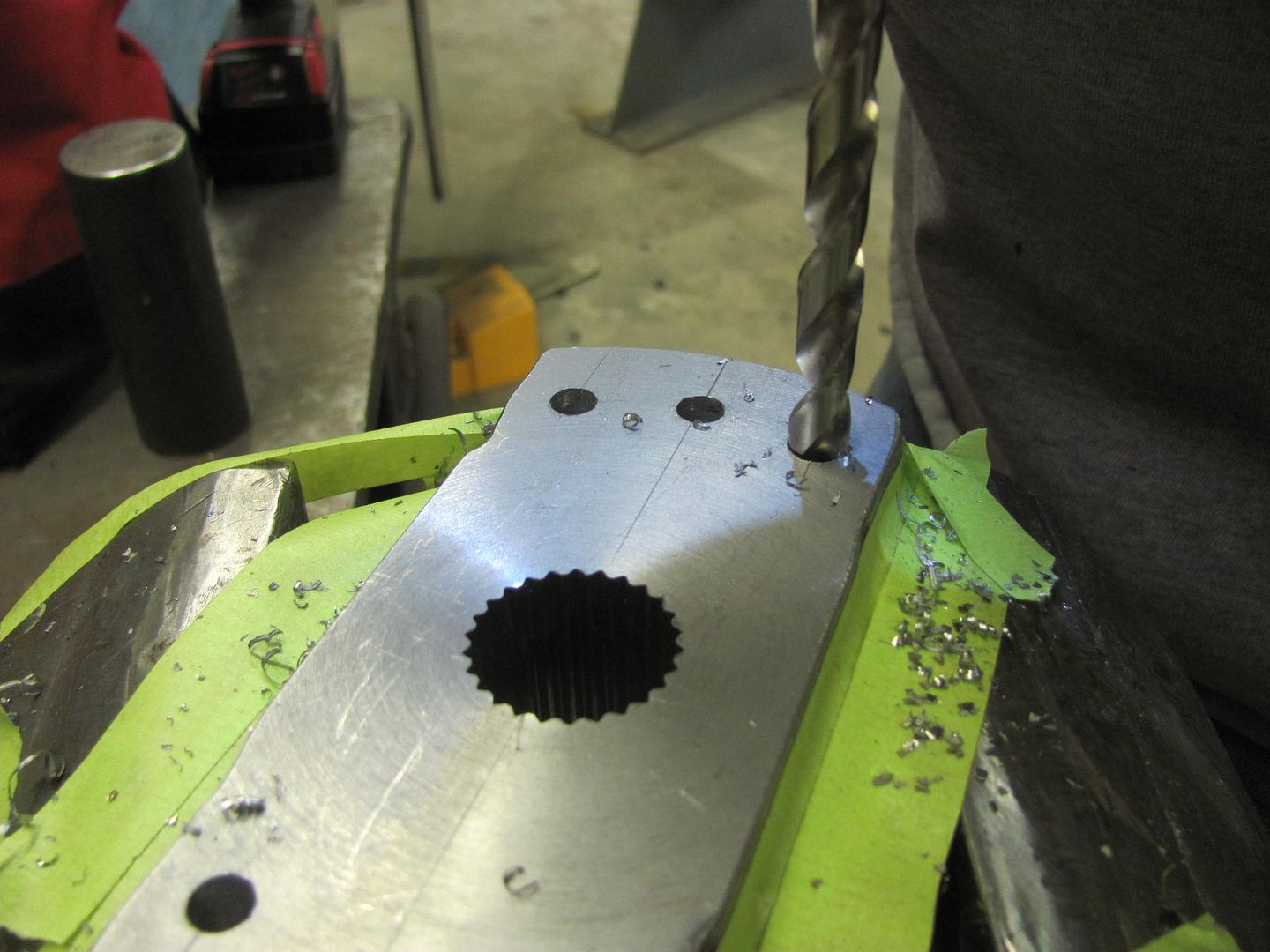

Meanwhile I got the holes (and some spares for height adjustment) drilled in the wheel hub flange...

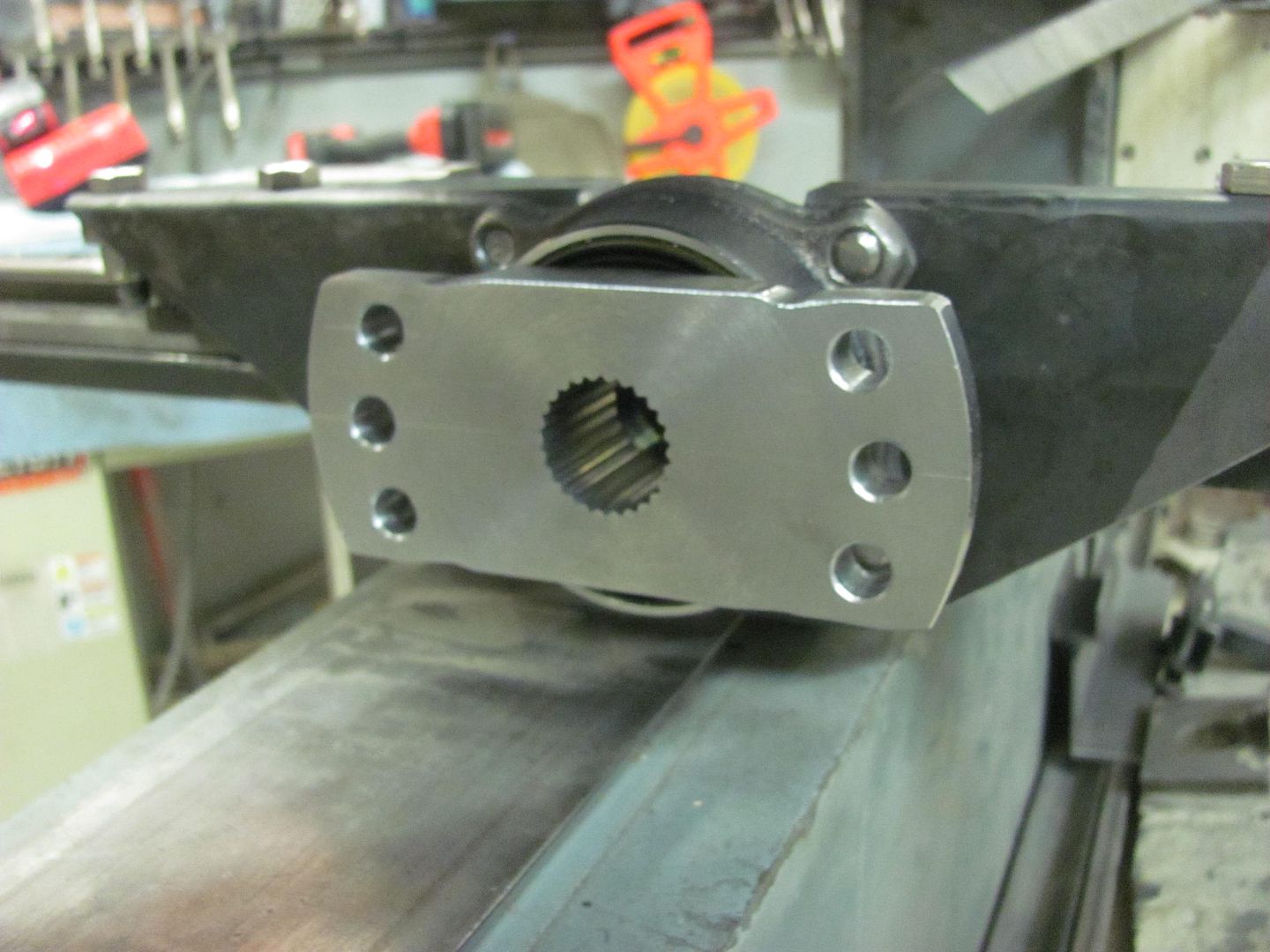

Clamps added...

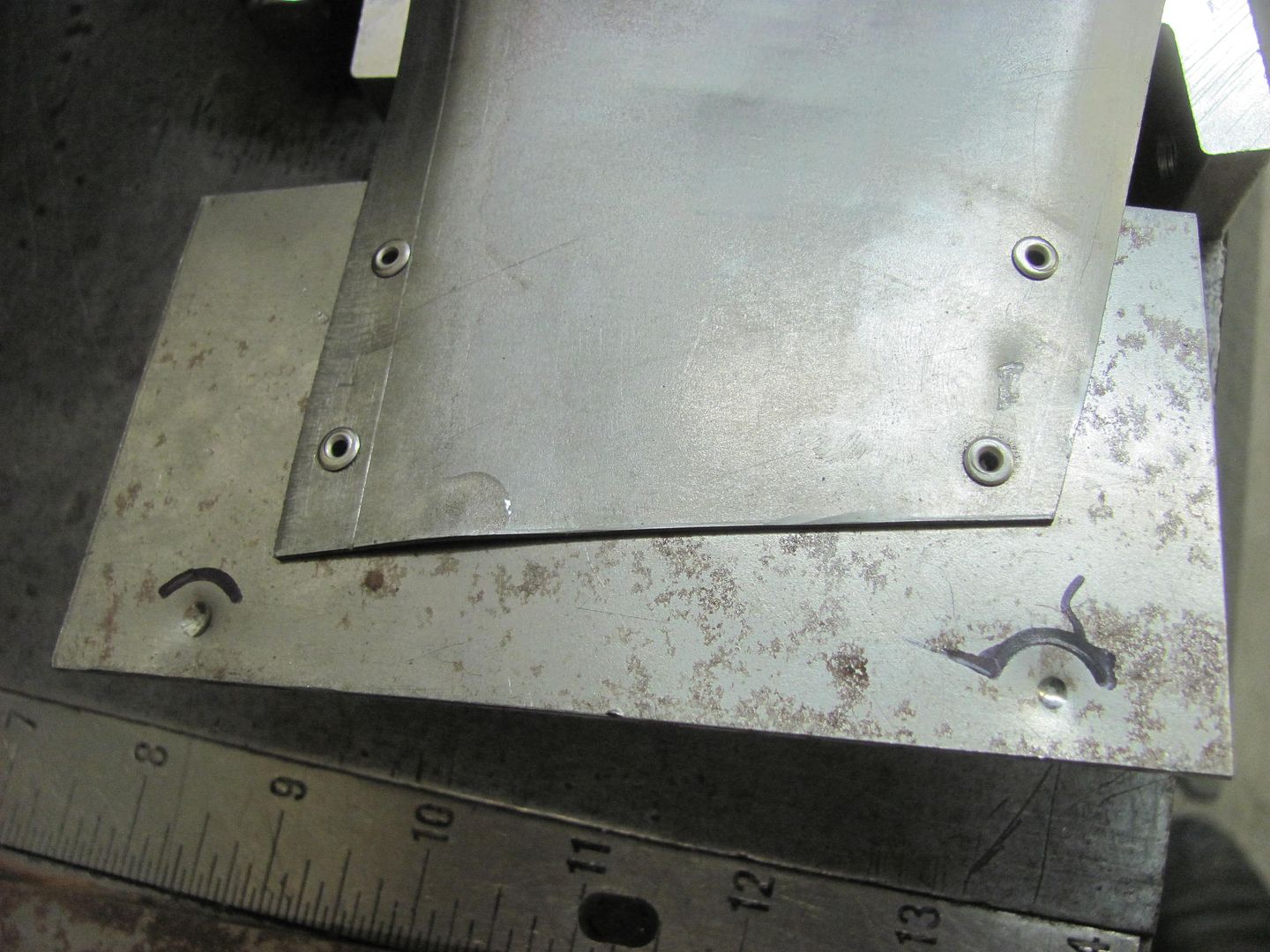

We used a "squaring plate" to align the panel for louver angle..

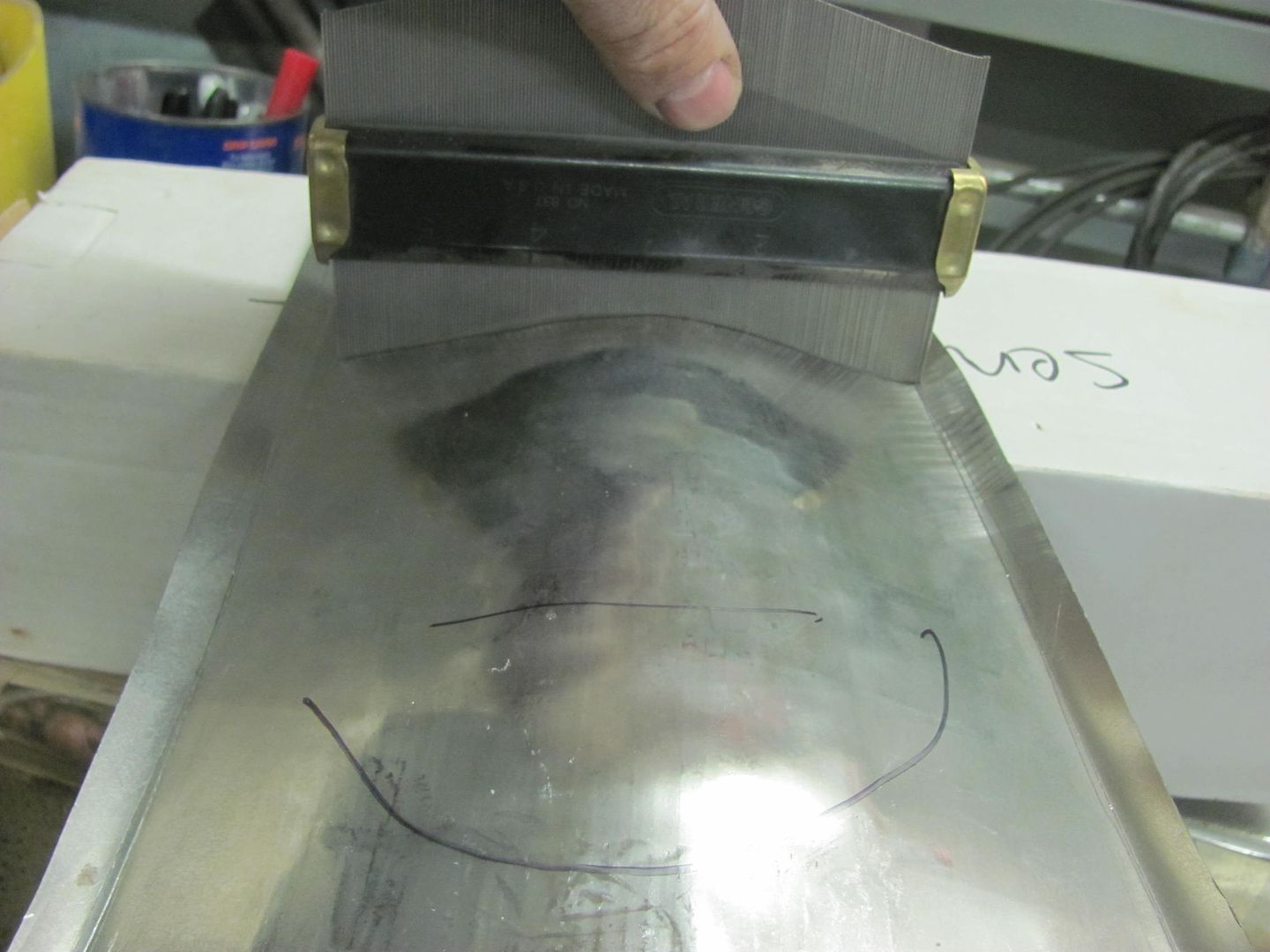

The punch needed some relieving to insure the corners didn't hit the inside radius of the panel...

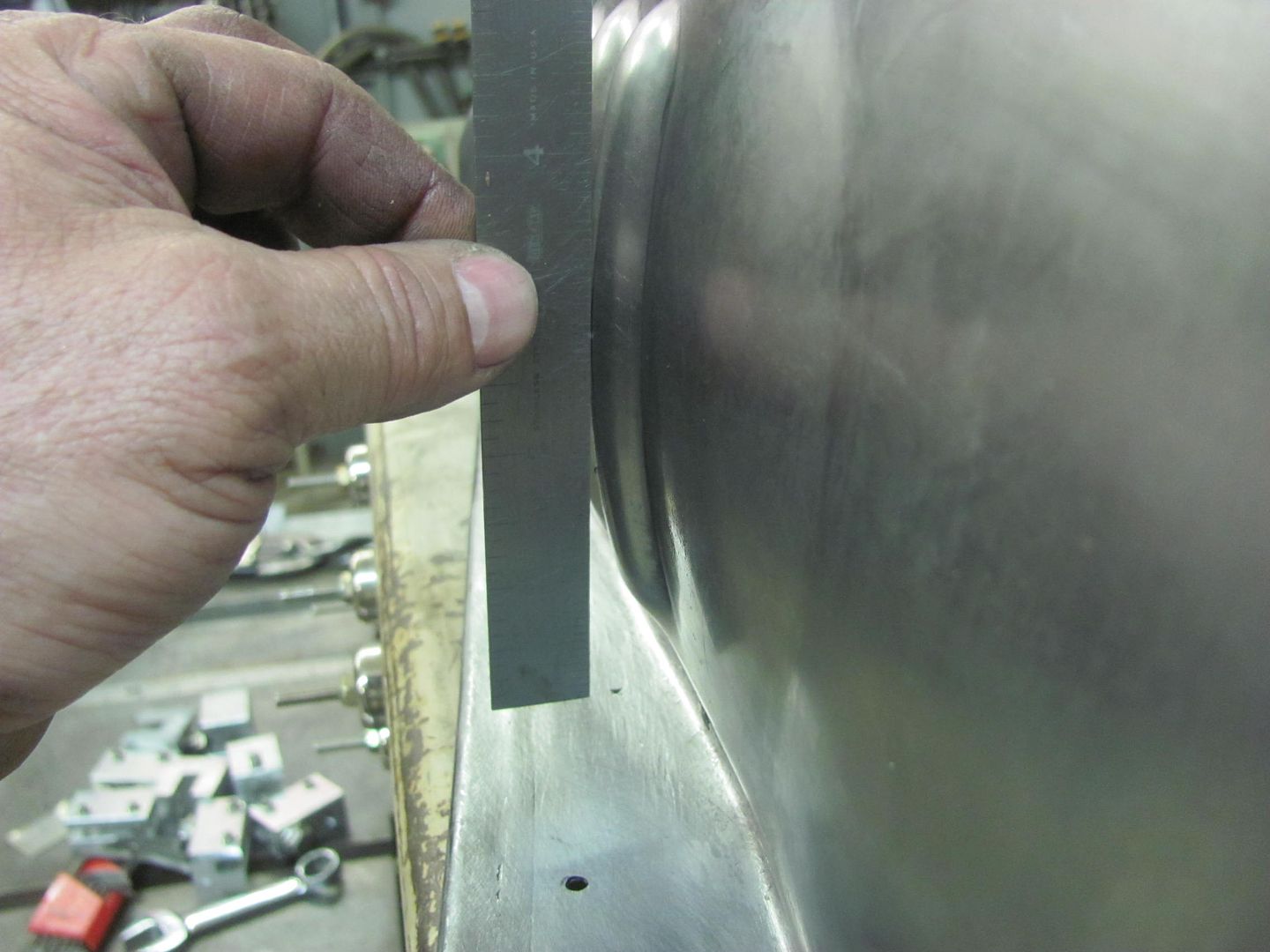

Cleaned up the grinder marks with a Scotchbrite pad..

Looking at the louvers...

Action shots:

https://youtu.be/EEyI10qb4BI

We have some more relieving to do on the tooling to eliminate some marking, then we'll do one more practice piece before breaking into the good stuff..Robert

-

Advertising

- Google Adsense

- REGISTERED USERS DO NOT SEE THIS AD

-

03-01-2016 09:07 PM #767

Send me your practice pieces. I'll find something to do with them..

Education is expensive. Keep that in mind, and you'll never be terribly upset when a project goes awry.

EG

-

03-02-2016 05:32 AM #768

You should see the scrap pile...

Robert

-

03-02-2016 07:51 AM #769

Does relieving the tooling effect the dies for use on flat surfaces?

Richhttp://www.clubhotrod.com/hot-rod-bu...del-coupe.html

-

03-02-2016 08:02 AM #770

Rich, I don't think I'm that close to affect it, but then I haven't tried it yet either. :fingerscrossed:Robert

-

03-03-2016 08:00 PM #771

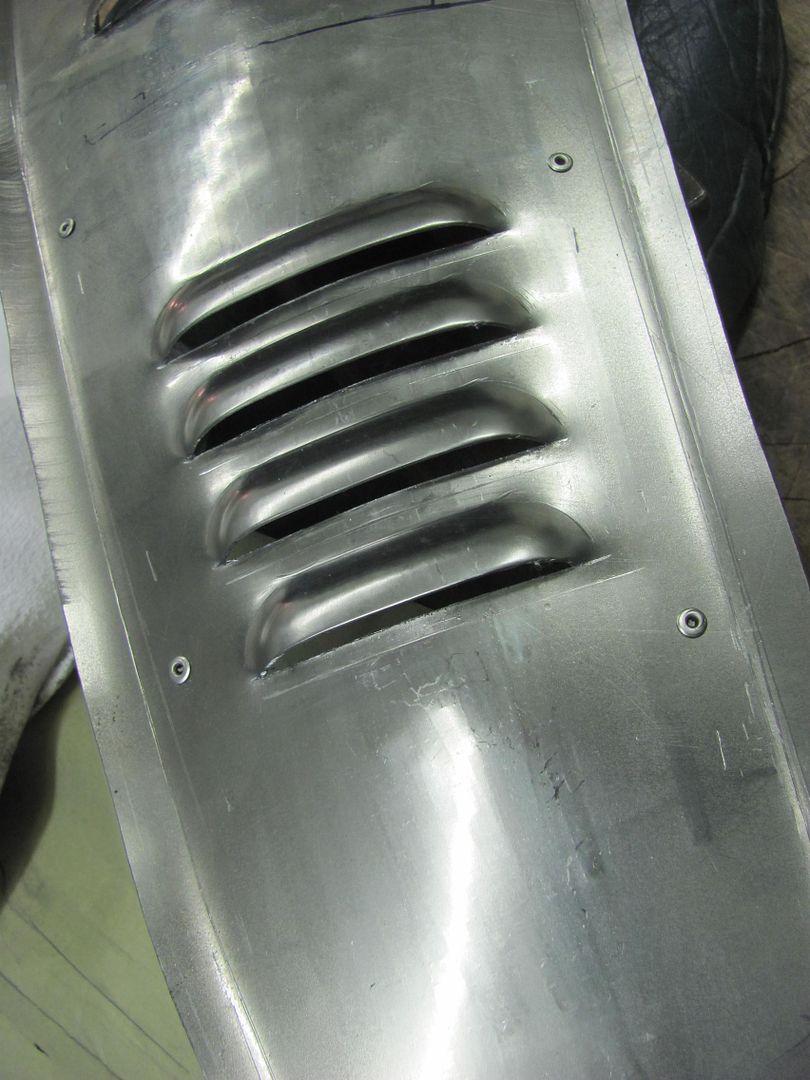

Here's the next practice panel as compared to Cody's inner fender panel..

Punching the louvers in the practice panel..

https://youtu.be/n3NVTILslbE

https://youtu.be/sHr2P60cqt8

Here's the moment of truth, the inner fender ready for punching...

Looks like our crown still exists!

another view....

https://youtu.be/7tcYNZ29WTg

One down, one to go..Robert

-

03-03-2016 08:46 PM #772

Awesome work. I had a '72 Chevy pickup with louvers everywhere, and always wondered how the builder did it.Jack

Gone to Texas

-

03-05-2016 04:31 PM #773

Jack, if all your louvers were of the same size, that would have been a single punch per louver rather than a reciprocating machine like we used..

Finished the driver's side inner fender this morning..

Now to get them back to Cody so he can do some more re-assembly..Robert

-

03-05-2016 05:03 PM #774

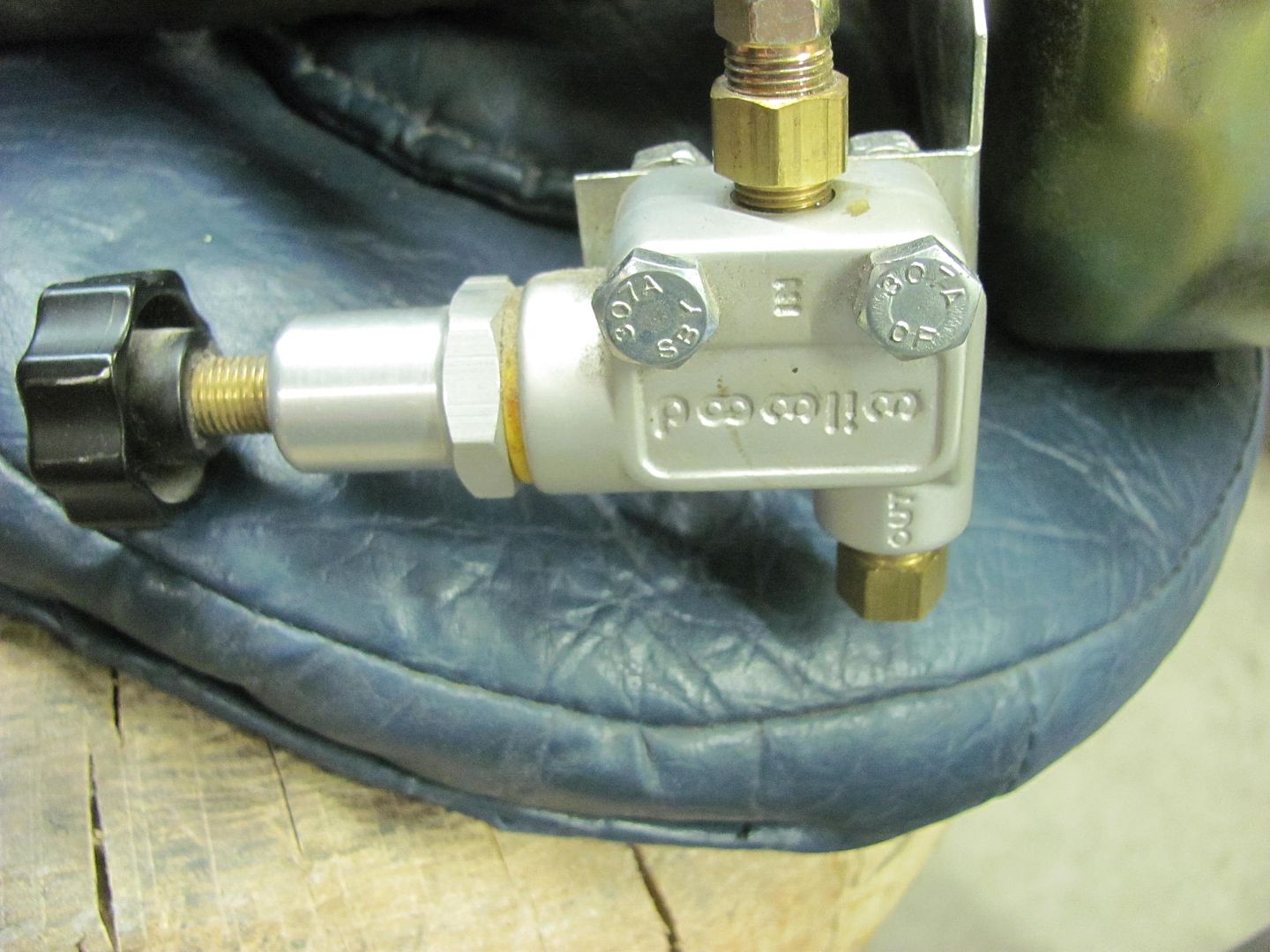

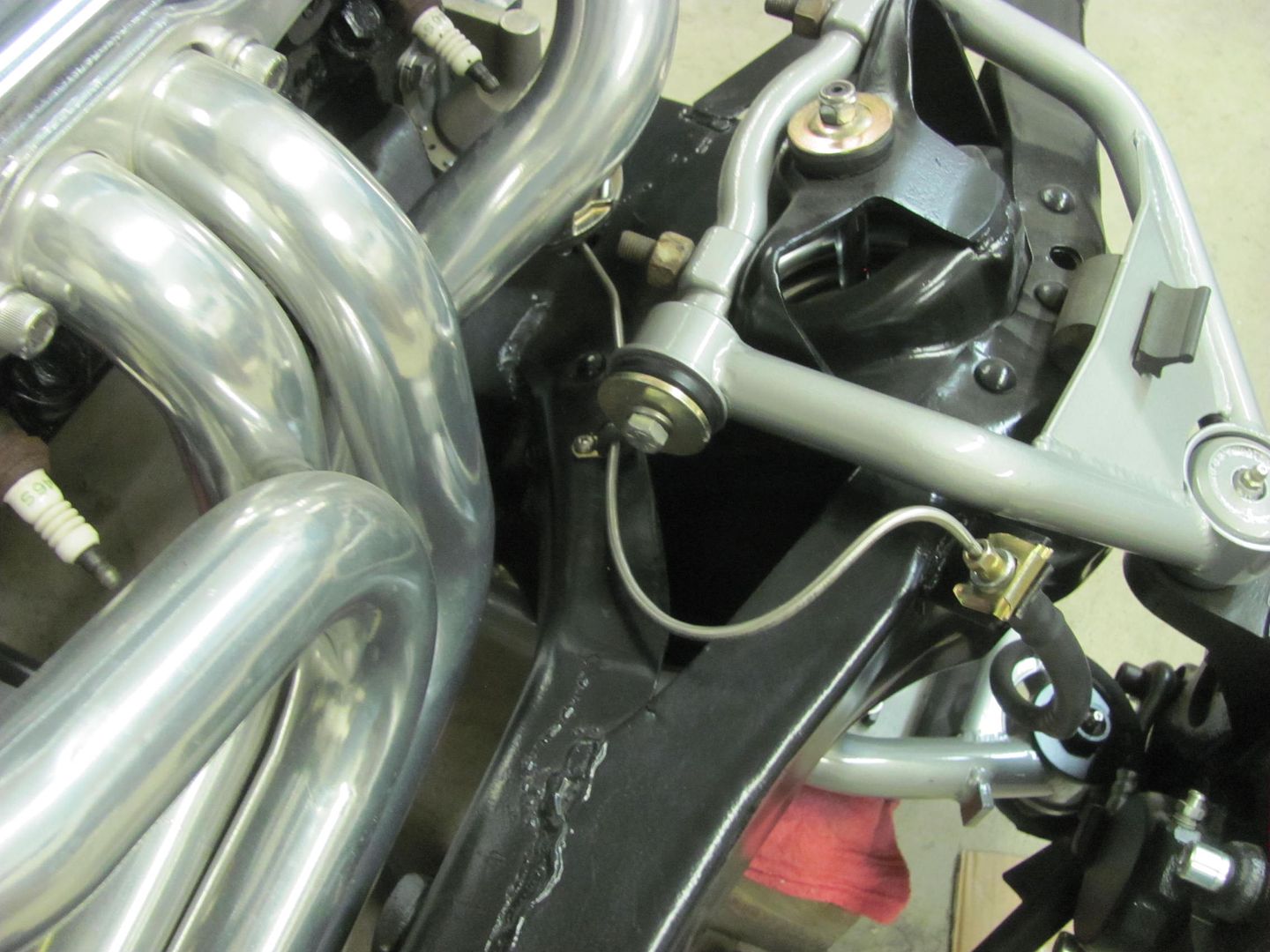

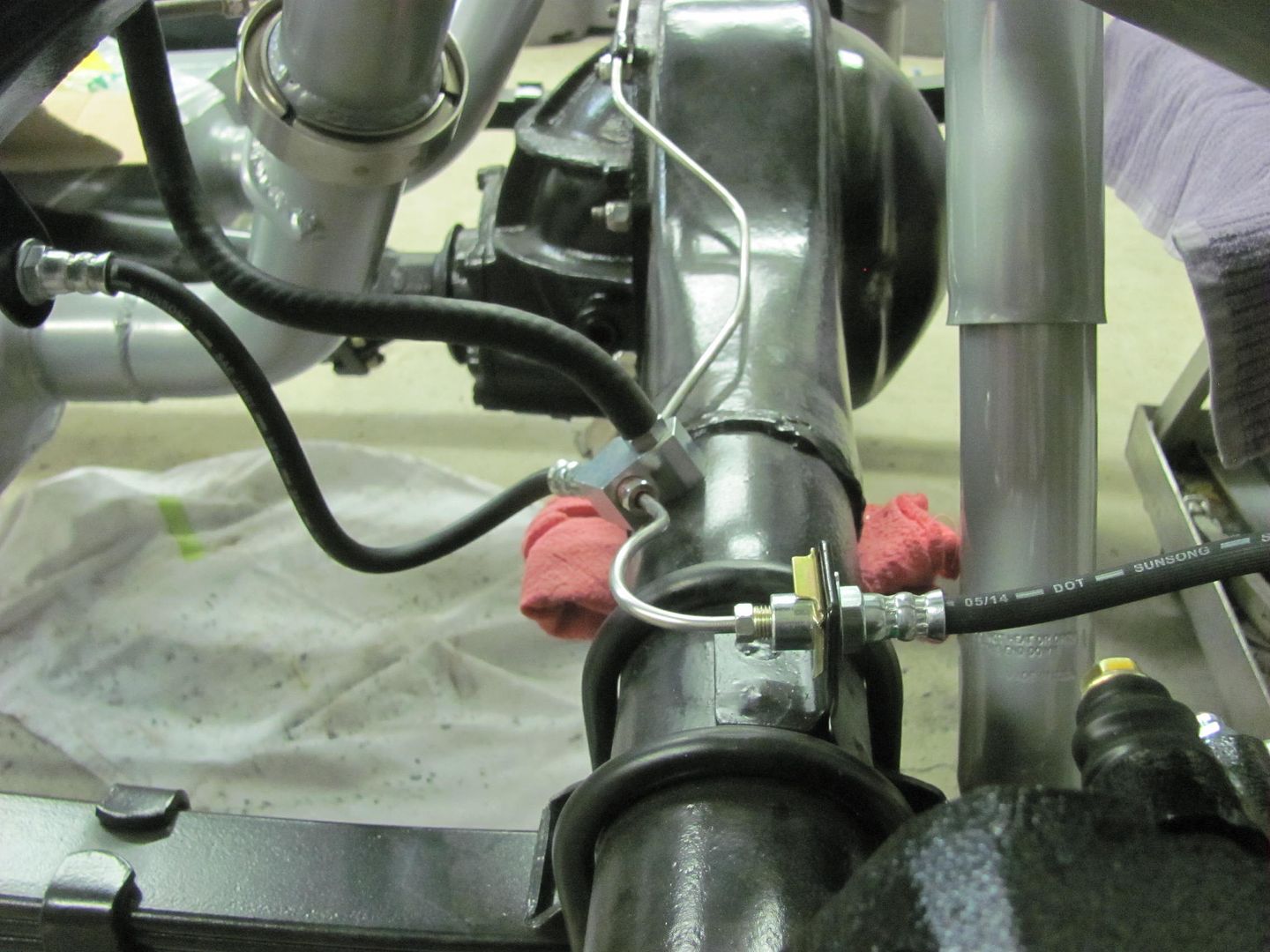

After finishing the louvers this morning, we turned our attention back to the wagon. We started installing the brake lines and found the "kit" the owner had purchased was far from a direct fit. here's the booster and master cylinder we're using...

As the kit had no lines to fit a 9" rear, we used a stick of stainless tubing that was left over from the Fairlane job and bent our own.

Robert

-

03-05-2016 05:10 PM #775

Wow, those louvers came out perfect, your problem solving on that project was amazing!

Richhttp://www.clubhotrod.com/hot-rod-bu...del-coupe.html

-

03-07-2016 09:50 AM #776

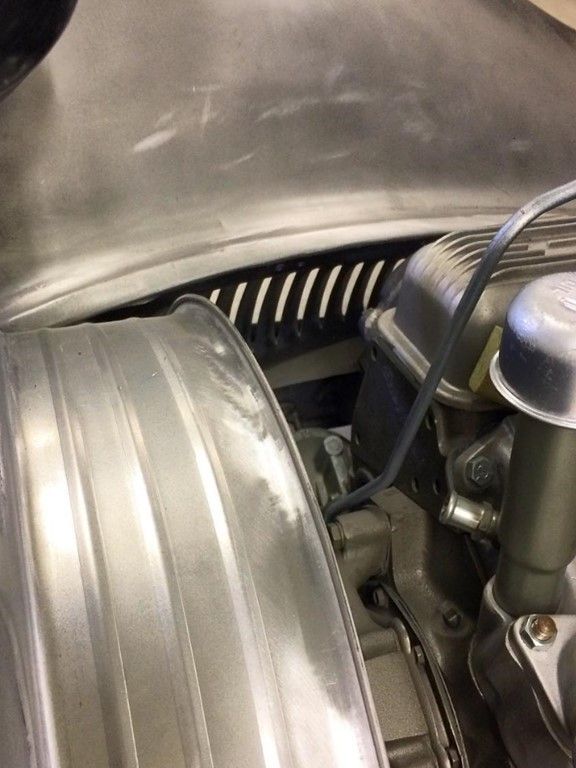

Thanks Rich! Well most small jobs I do like this you never see the part installed (like the Studebaker dash parts) so I was happy to see Cody post up some pictures this morning. Here's a shot of the passenger side installed.. It was nice to take on a challenge like this and see it actually work..

I think Kyle enjoyed the break from blocking epoxy primer.. Now back to the old grind..Robert

-

03-07-2016 11:43 AM #777

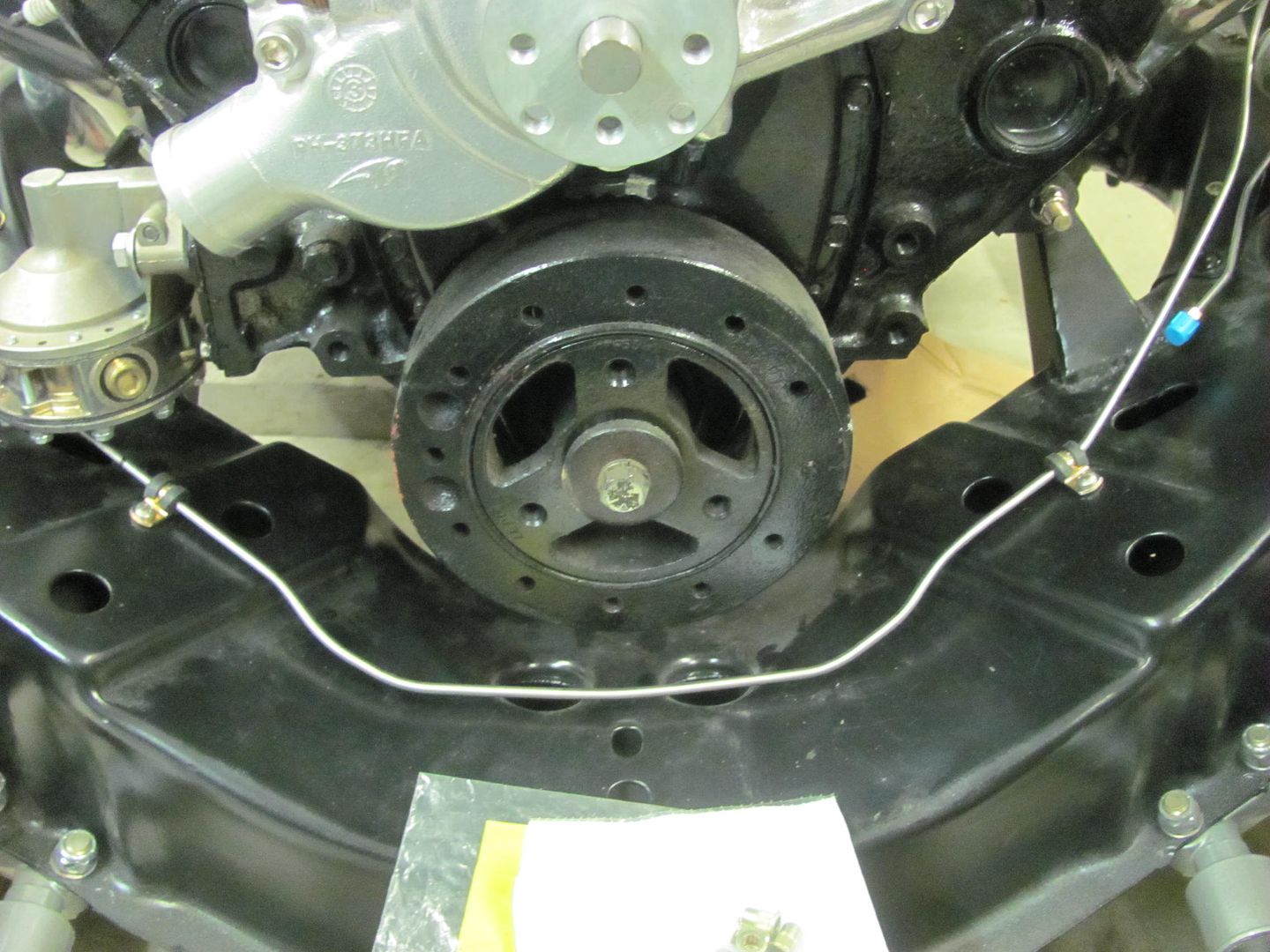

never seen a front drum like that or is it in front of a disc? to cool?"  "No matter where you go, there you are!" Steve.

"No matter where you go, there you are!" Steve.

-

03-07-2016 11:56 AM #778

TMK it's a disc coverRobert

-

03-08-2016 06:54 PM #779

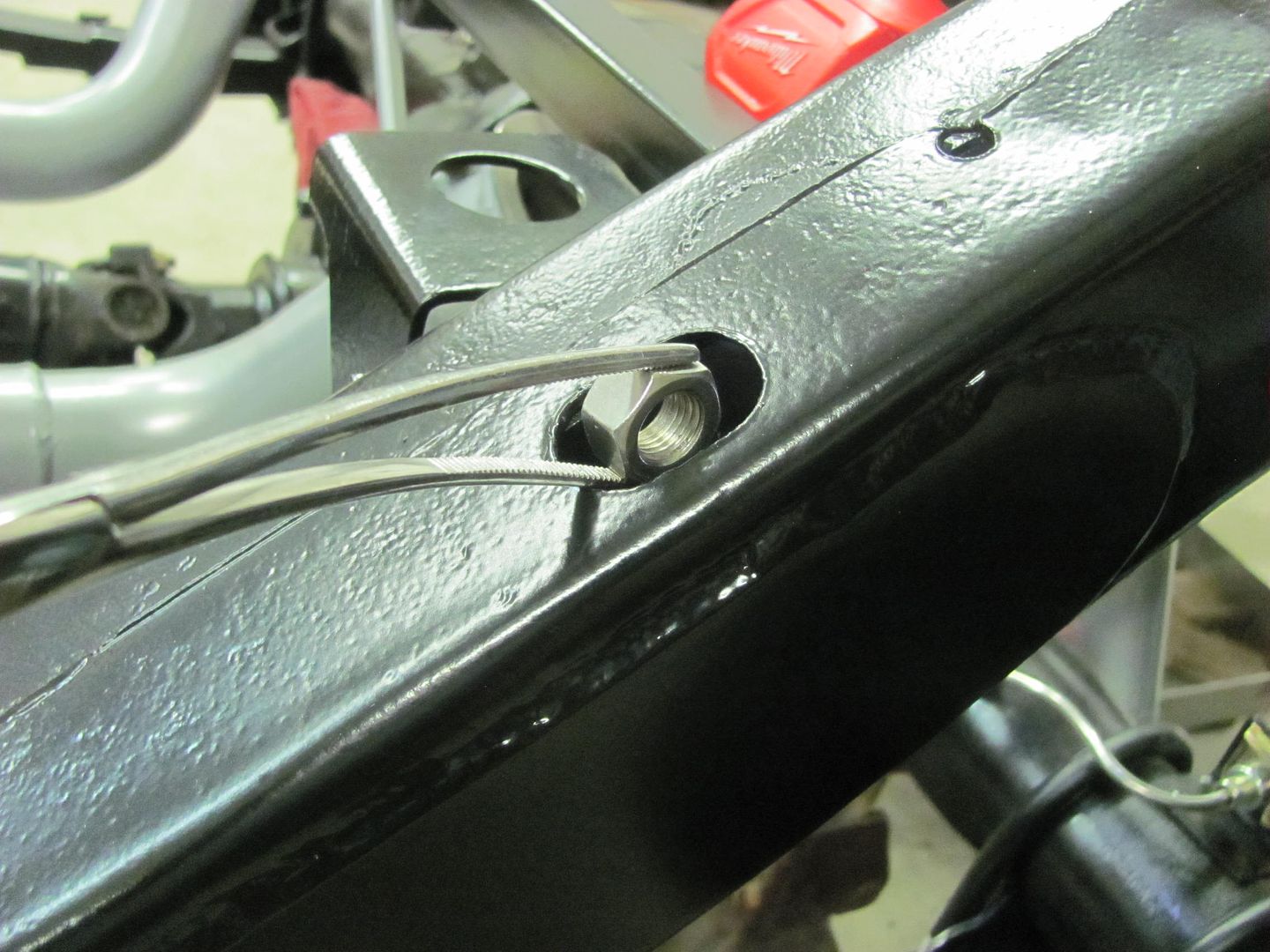

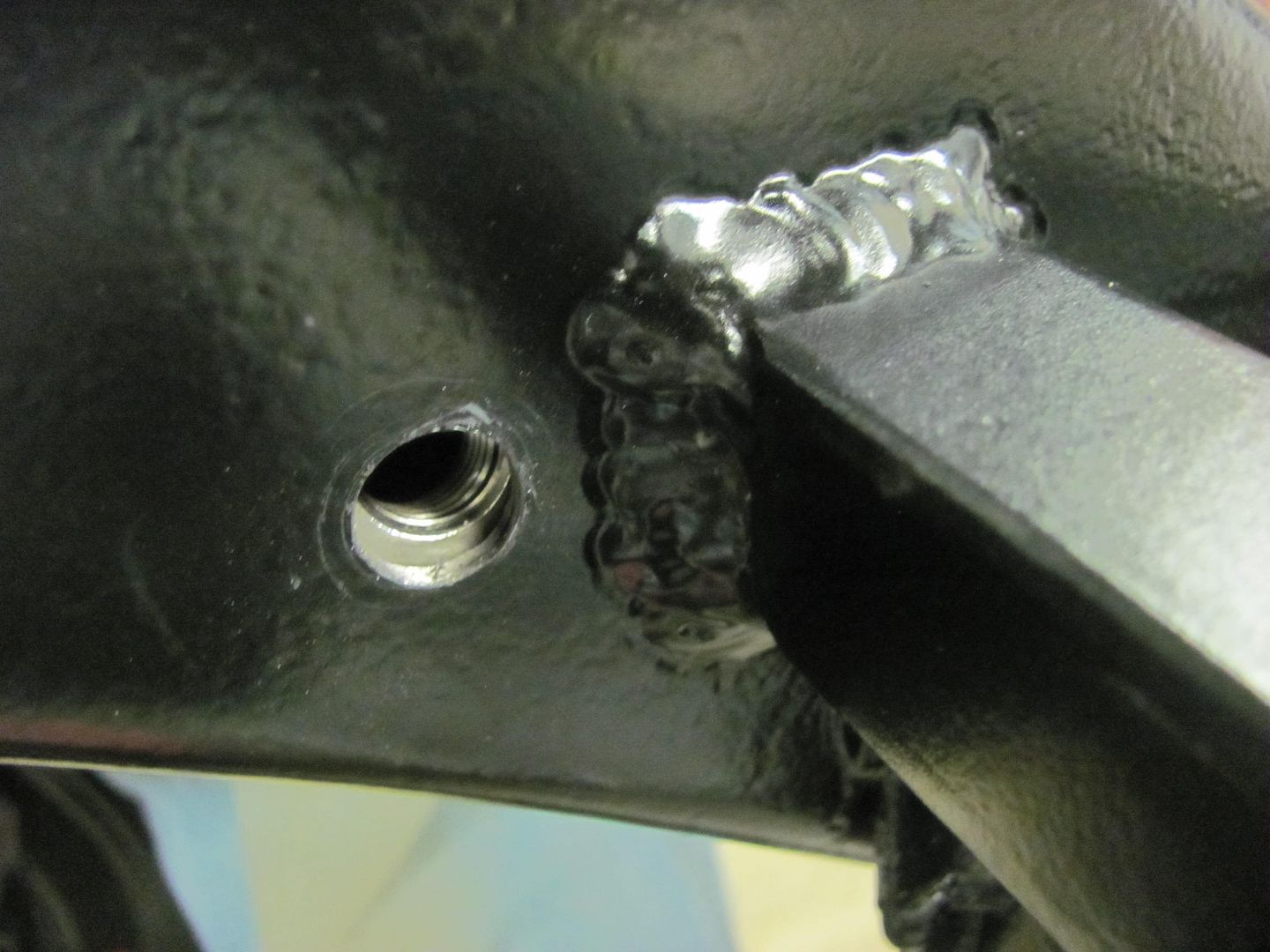

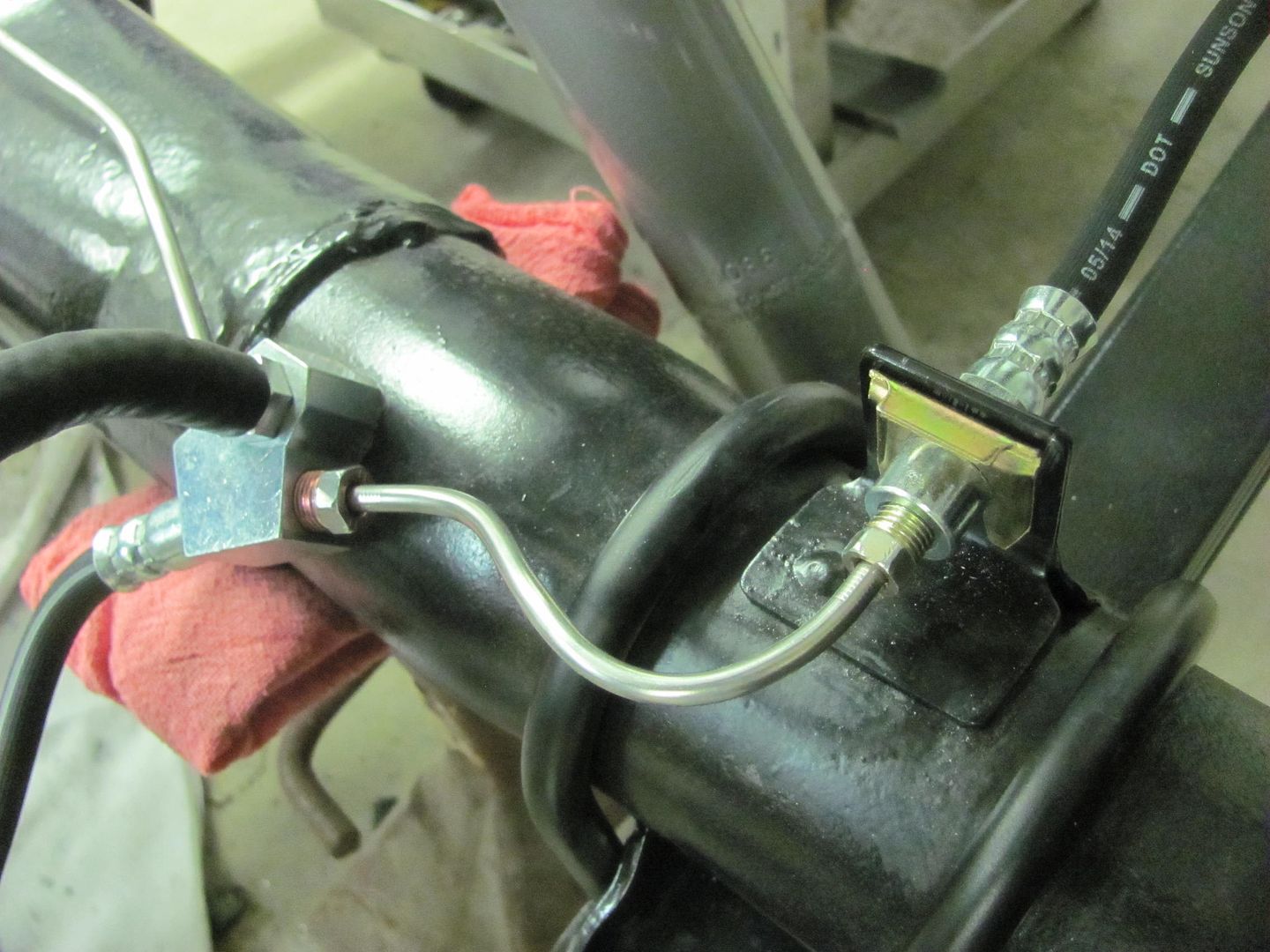

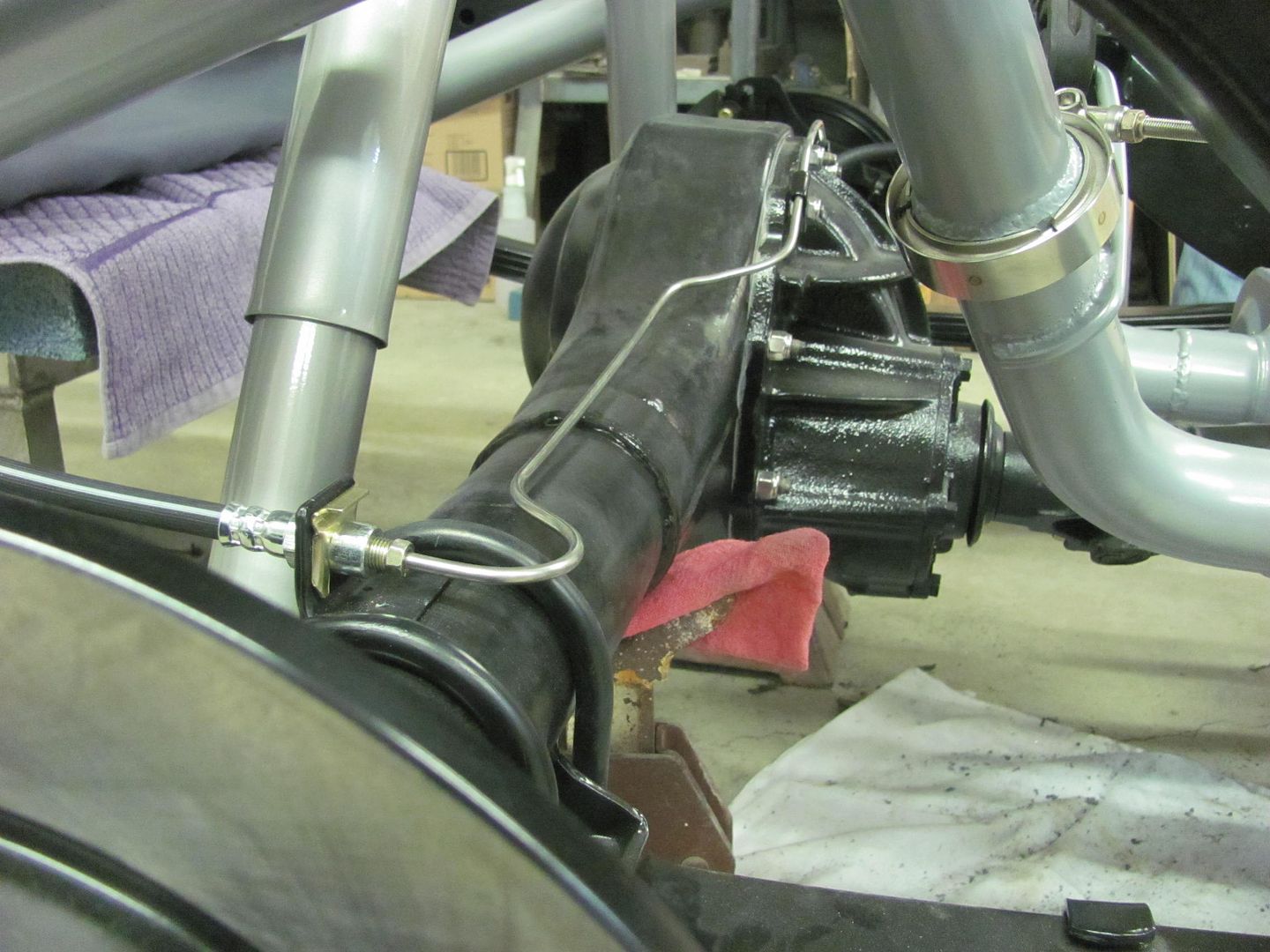

Adding the rear axle vent hose, we needed a spot to anchor the second vent fitting to keep the hose from flopping around...

Which is threaded with a 7/16-20 thread

With Loctite added to the threads...

More SS brake lines...

With the rear brake lines complete, the rear wheels were bolted back up..

And for our lessons learned, this is what happens when you cut 12 gauge steel with a square on the other end of the shear. Dan, the blades are still sharp!

Robert

-

03-08-2016 07:54 PM #780

Weld it back together.

It'll be alright.

johnboy

Mountain man. (Retired.)

Some mistakes are too much fun to be made only once.

I don't know everything about anything, and I don't know anything about lots of things.

'47 Ford sedan. 350 -- 350, Jaguar irs + ifs.

'49 Morris Minor. Datsun 1500cc, 5sp manual, Marina front axle, Nissan rear axle.

'51 Ford school bus. Chev 400 ci Vortec 5 sp manual + Gearvendors 2sp, 2000 Chev lwb dually chassis and axles.

'64 A.C. Cobra replica. Ford 429, C6 auto, Torana ifs, Jaguar irs.

3390Likes

3390Likes

LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks Reply With Quote

Reply With Quote

I'm happy to see it back up, sure hope it lasts.

Back online