Thread: 55 Wagon Progress

-

03-28-2021 09:47 PM #1606

Thanks gents!!!

Progress from yesterday, while Jared was blocking out some of the window garnish moldings, I worked on the door panel stainless trim to ready them for stud welding. Mike had used the trim repair tool to remove the dings, which were then filed smooth.

The last 65 years had left their mark; we had numerous scratches needing removal as well. We started with 320 grit on the fine pattern palm sander, and progressed our way up to 8000 grit trizact..

This is the final using the 8000 grit, and we'll start the buffing process once the stud welding had been completed..

https://www.youtube.com/watch?v=n5YYWcQgIRg

With the stainless prepped, we turned attention to the window garnishes. They were sprayed with three coats of SPI epoxy.

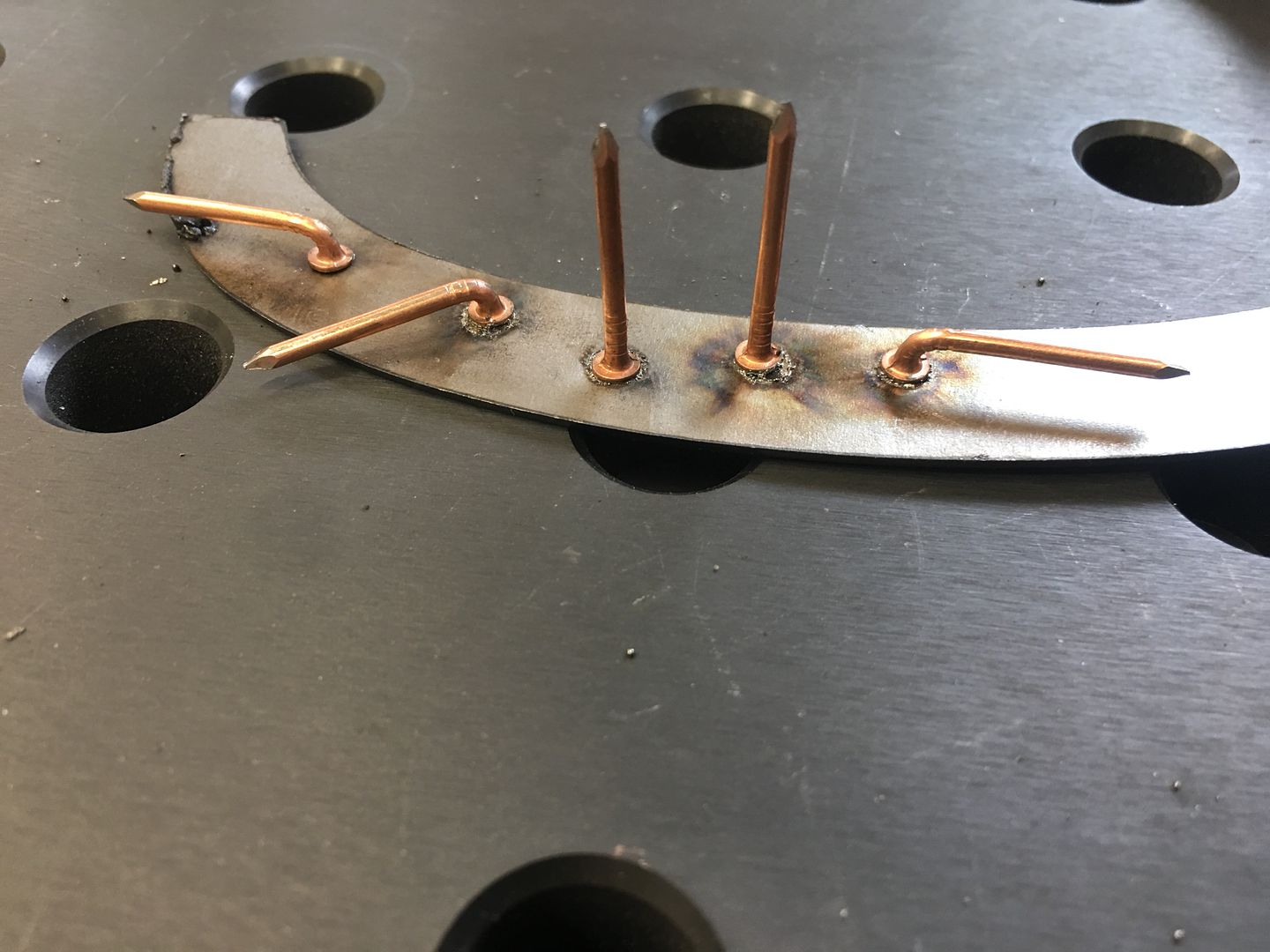

Today we went to A&A Metalworks in Ridge MD to get the studs welded in place. This sample shows the studs, where three have been folded over to a 90. This is how the factory held them onto the door panels as well. Note the back side shows no heat pattern with the Capacitive Discharge welder.

Welding the studs onto the stainless trim...

https://www.youtube.com/watch?v=7WZ25tqOXos

Our results...

https://www.youtube.com/watch?v=YXQCJe1hma8

A test to check the heat the welder introduces into the panel..

https://www.youtube.com/watch?v=DkDRJXstvH4

This shows these welders make a good choice to use where cases of heat sensitivity may be an issue.Robert

-

Advertising

- Google Adsense

- REGISTERED USERS DO NOT SEE THIS AD

-

03-29-2021 11:18 AM #1607

Very cool polishing and welding, you guys are great for taking the time to post the process"  "No matter where you go, there you are!" Steve.

"No matter where you go, there you are!" Steve.

-

03-29-2021 12:58 PM #1608

Robert.. as always. WOW, just WOW! I'll echo Steve, thanks for teaching and posting.

-

03-30-2021 09:41 PM #1609

Thanks guys. When we started I wasn't sure we could reuse these pieces of trim as they were missing a good half of the studs. We tried these and had good luck with the Capacitive Discharge welder in not introducing any heat to speak of (and thus heat damage that you'd see from a normal welder) it was too good a result not to share in case someone else needs such a repair. I would say the welder costs about 2000+, so unless you need one REAL bad, find someone with such a machine to perform the welds for you. Allen did have quite a few of the studs left, as well as threaded ones from 4-40 up 1/4-20. If anyone needs such repairs I'd be happy to act as a go between if you couldn't find such a service locally.Last edited by MP&C; 03-30-2021 at 09:45 PM.

Robert

-

04-04-2021 09:43 PM #1610

Happy Easter everyone!

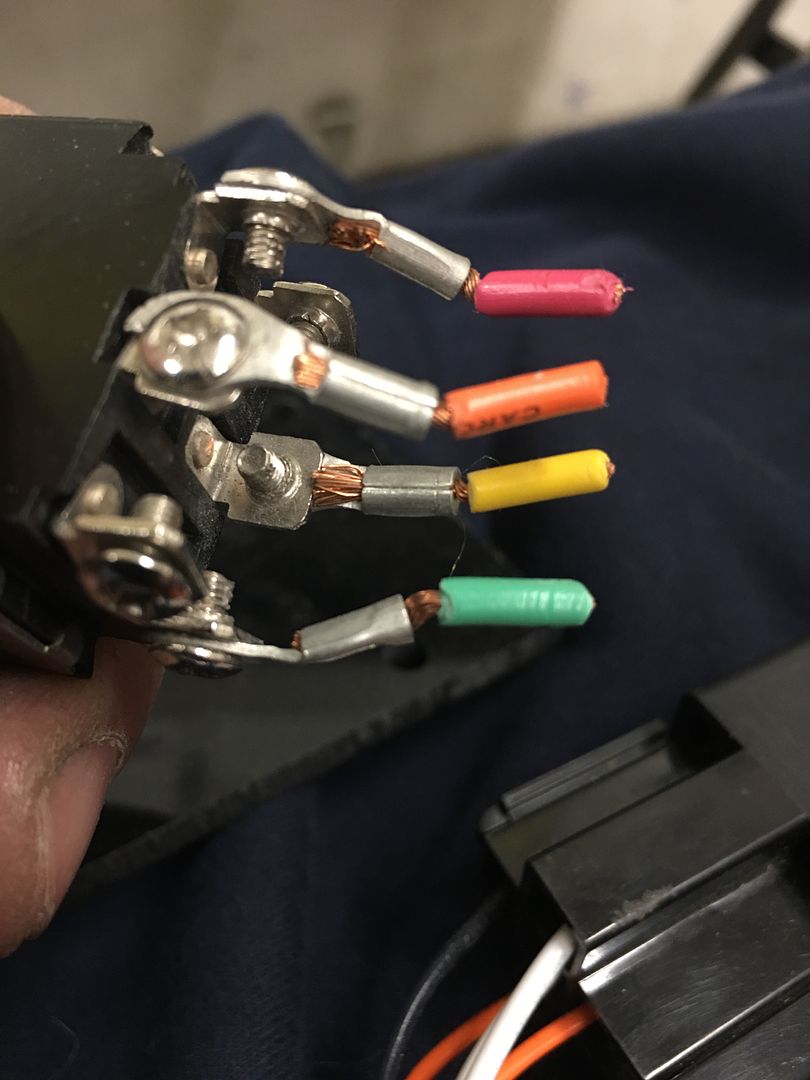

Our wagon progress from this weekend, we finished up the interior lights. Here wiring up the rear light. The included pigtails were discarded to eliminate a butt splice, and our newly installed wiring made use of new lamp base contacts (W crimp) from Repair Connector.

The lens used in light fixtures like these are typically plagued over the years by overheating and then cracking, so we opted for a 1004 LED replacement. Should keep things cooler for longer lens life, and brighter!!

Onto more electrical issues, the "hidden fuel door" we had purchased was so intermittent in operation that when we had dropped it off at Absolute Rod & Custom Paint to test fit to the car when they were fine tuning the bodywork, we were second guessing whether we should use it at all.

https://www.youtube.com/watch?v=848V2PbuQJw

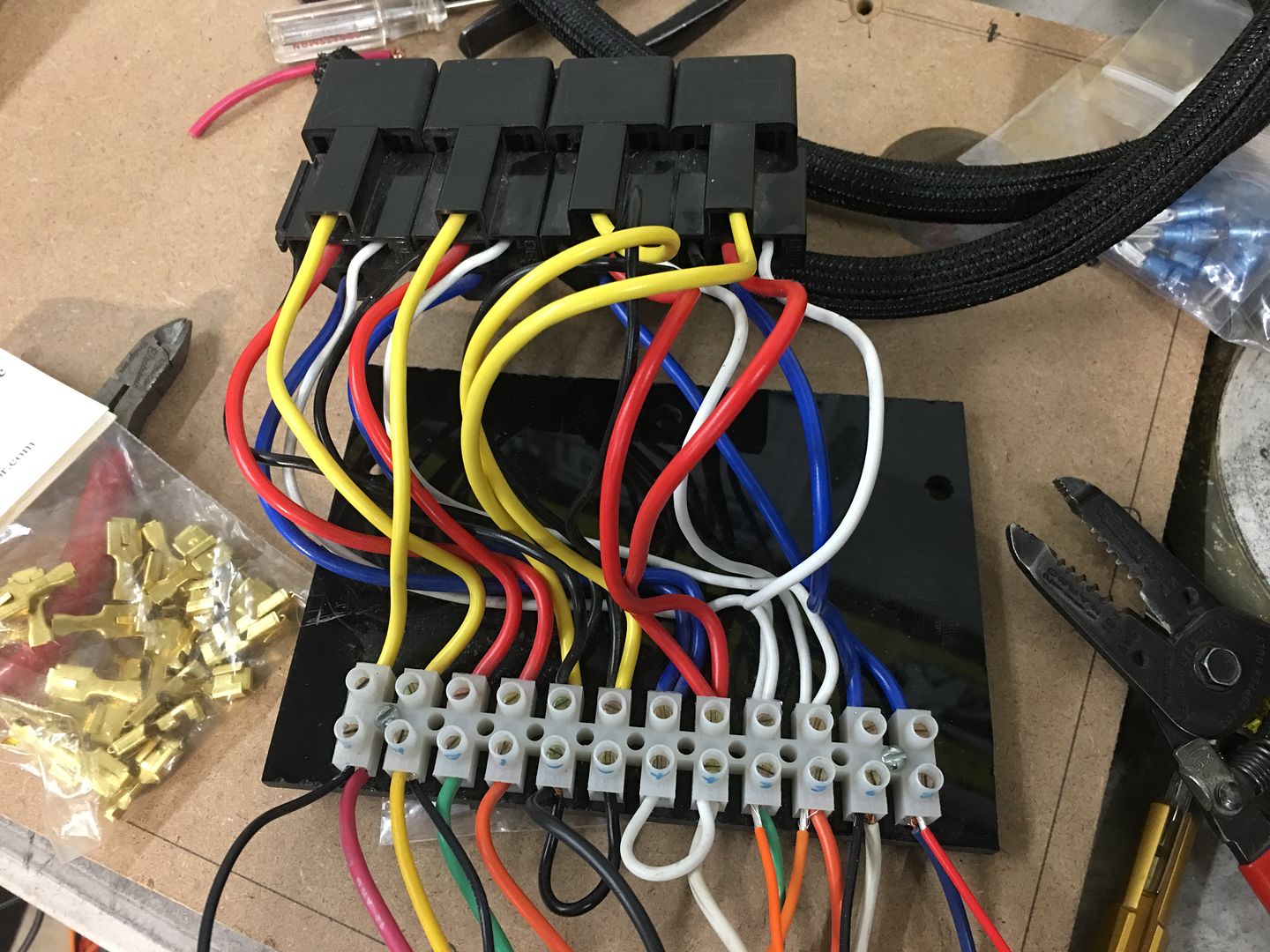

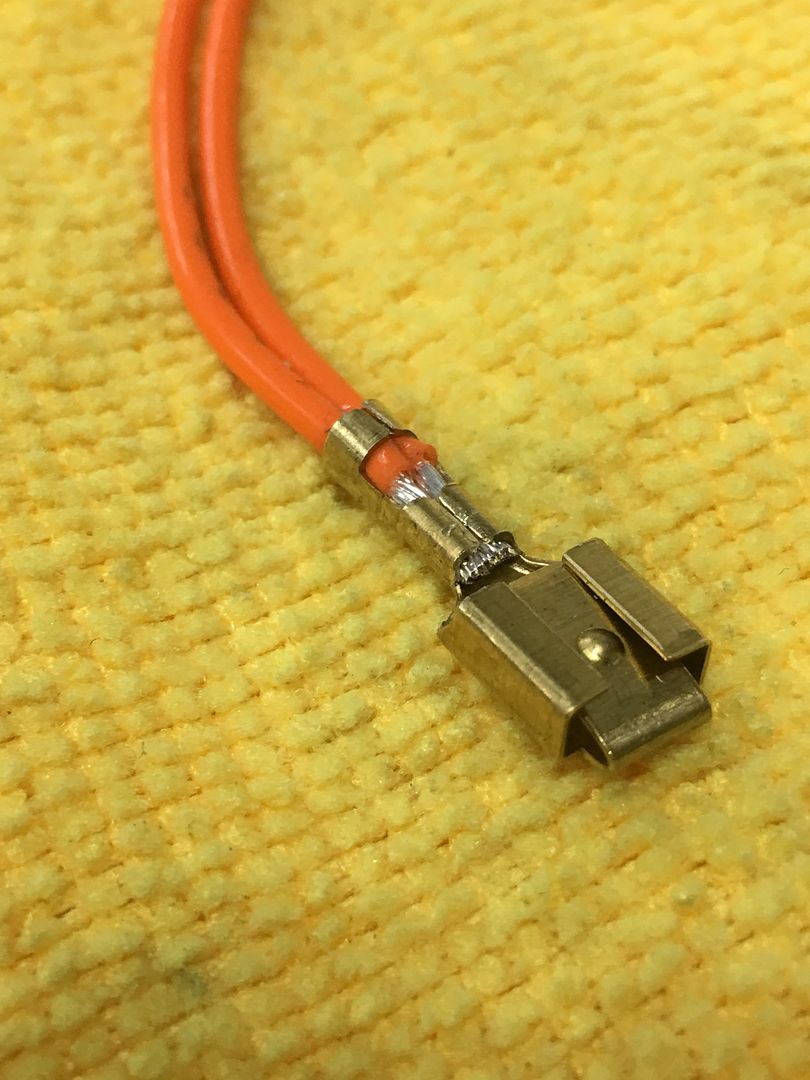

All the harnesses came into a terminal board with wires going to the relays on the opposite side. Some of the terminals had as many as three wires in them, and Mike Flores found about 6 loose wires. Splices didn’t carry the same wire color through, making trouble shooting a bit of a challenge. The toggle switch (which should have been momentary contact but was not) had some home-made fork terminals. This thing was looking more sketchy with everything we looked at next. For a store-bought product intended for an automotive environment, they should find someone more competent in wiring.

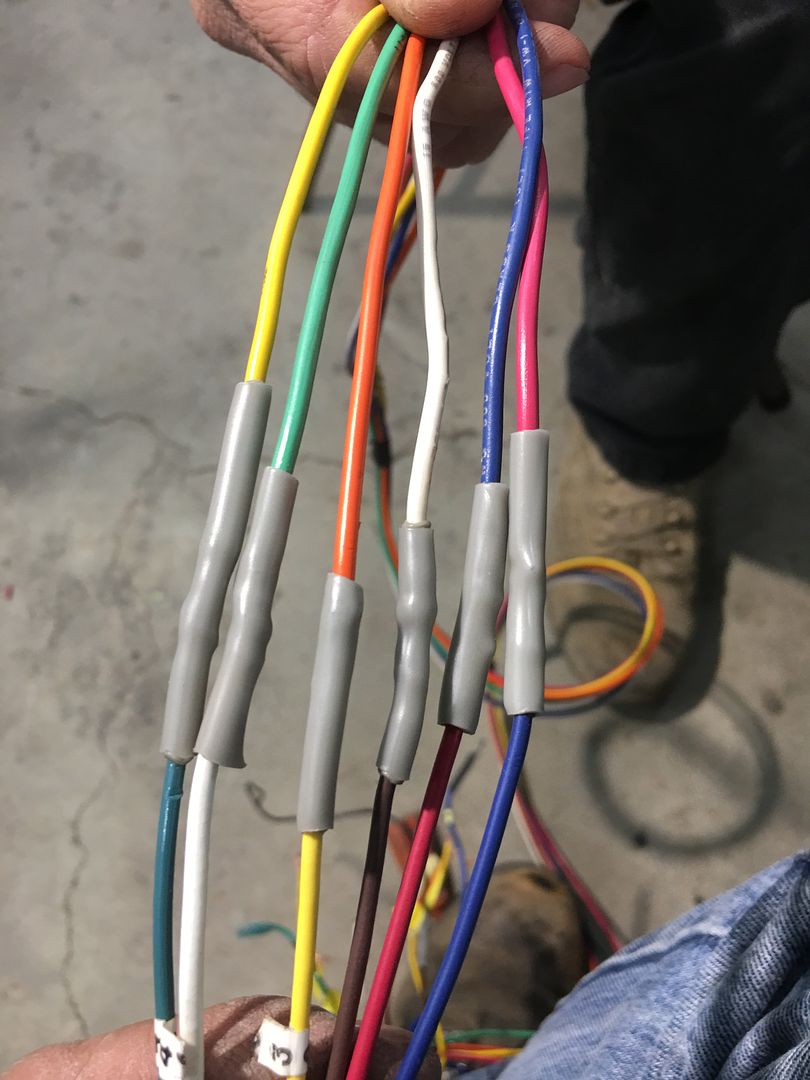

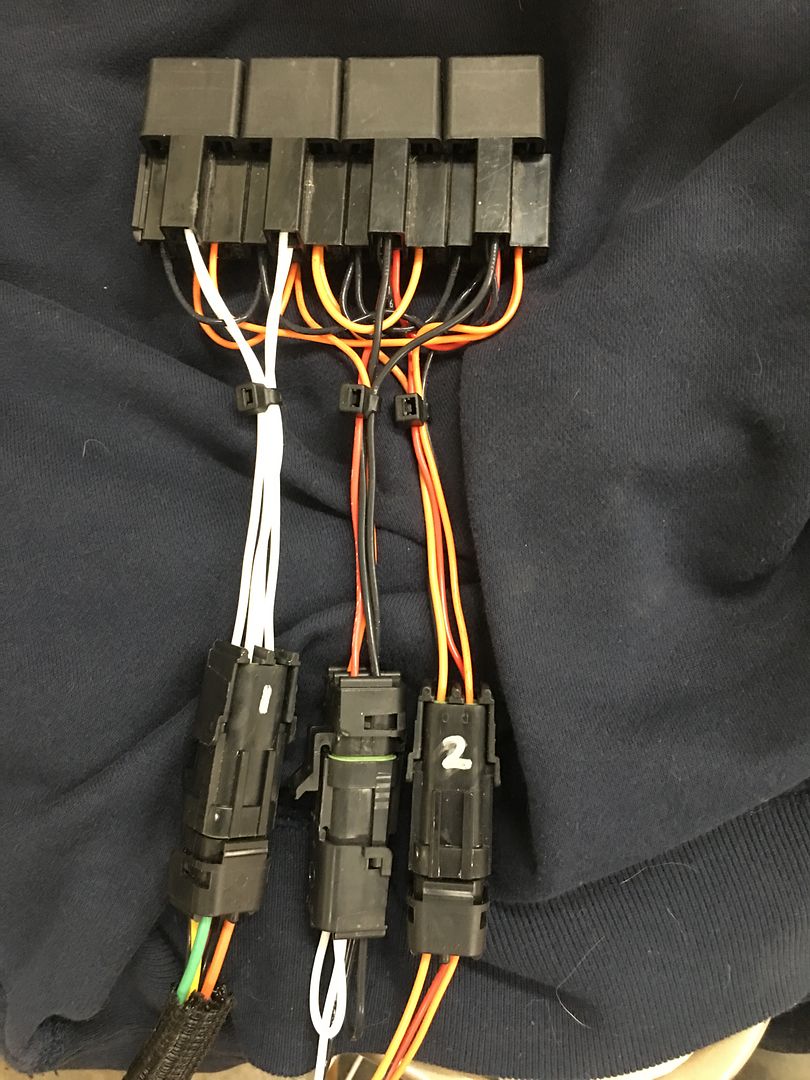

To get rid of the terminal board, we opted for weather pack connectors, one to each of the end terminations (switch, fuel door, power source). We eliminated the triple wires to single terminal by jumpering, making use of two wires in a single pin, and jumpered as required.

Our new wires going into the relay connectors made use of new Packard 56 style female spade terminals from www.repairconnector.com (more W-crimp) These were also jumpered two wires to a pin where needed.

The toggle switch was replaced by an automotive grade MOMENTARY rocker switch from McMaster. Works flawlessly.

https://www.youtube.com/watch?v=wxGo6JU19kY

Not pretty, but much improved. The relays will be located behind the rear seat on the sub box, conveniently between all our end points. Just like our speaker grilles, black plastic really doesn't belong in plain view in a 55 Chevy. So our more highly functional rocker switch will be hidden inside the glove box..Robert

-

04-05-2021 12:04 PM #1611

Wow the details you fabricate/modify are NASA quality controlled! Amazing! Cool automated behind the headlight gas tank access. LEDs are a smart mod too. My house is 95% led, and things like the 89 Harley Benefit from the rear tail light having an LED that isn't affected by filament failure from vibration. I try to replace what I can as I am in need of a bulb with an led option. If only they meade leds that worked in range oven! Heat problems evidently are too hot of an environment for the led appliance bulb to work."  "No matter where you go, there you are!" Steve.

"No matter where you go, there you are!" Steve.

-

04-15-2021 05:15 AM #1612

- Join Date

- Apr 2011

- Location

- Prairie City

- Car Year, Make, Model: 40 Ford Deluxe, 68 Corvette, 72&76 K30

- Posts

- 7,301

- Blog Entries

- 1

Very nice work! The electrical is always over looked on most builds and can cause you the most trouble!

.Ryan

1940 Ford Deluxe Tudor 354 Hemi 46RH Electric Blue w/multi-color flames, Ford 9" Residing in multiple pieces

1968 Corvette Coupe 5.9 Cummins Drag Car 11.43@130mph No stall leaving the line with 1250 rpm's and poor 2.2 60'

1972 Chevy K30 Longhorn P-pumped 24v Compound Turbos 47RH Just another money pit

1971 Camaro RS 5.3 BTR Stage 3 cam, SuperT10

Tire Sizes

-

05-05-2021 09:38 AM #1613

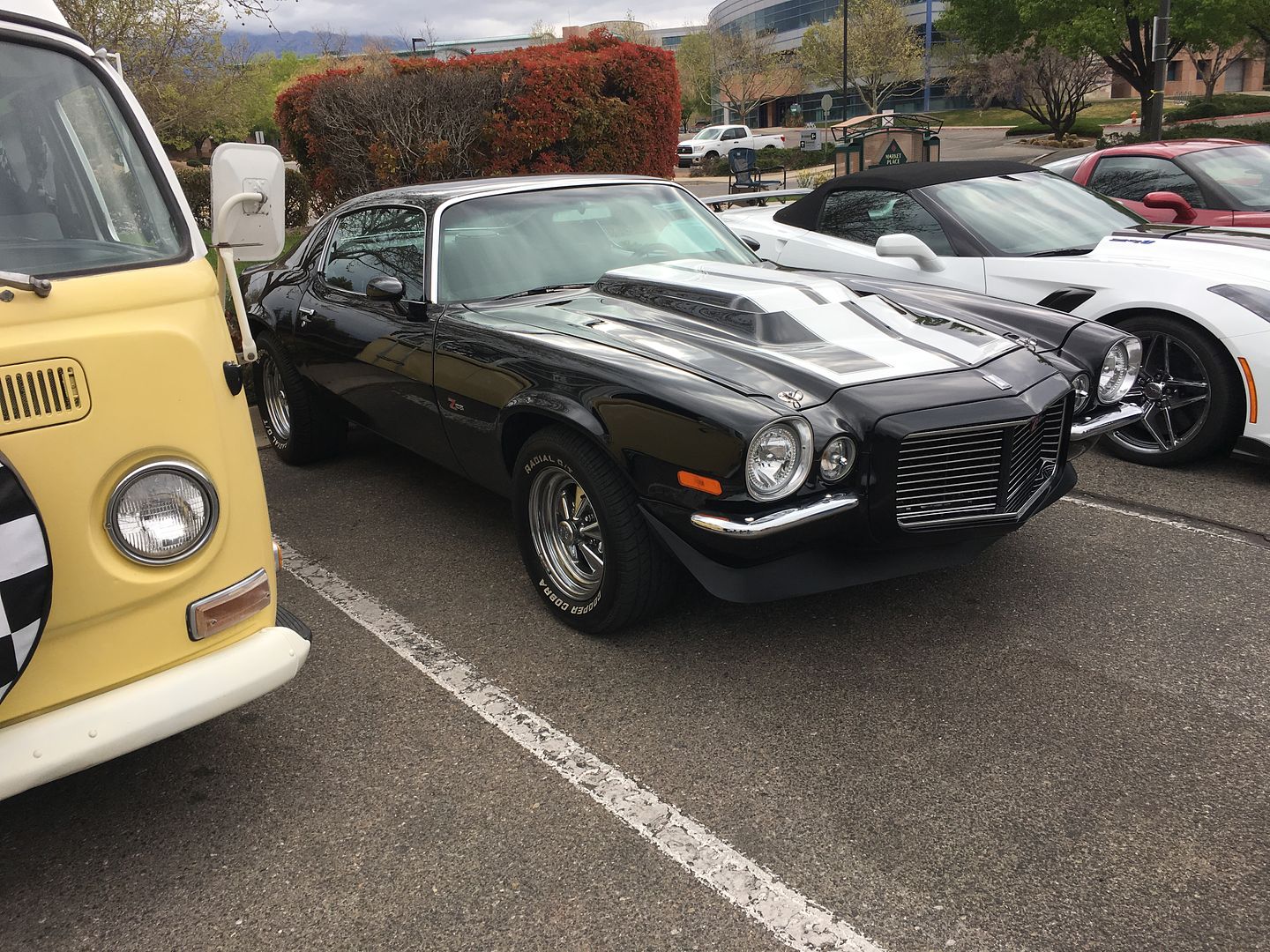

So now that I'm back from the short hiatus in Albuquerque, hanging TV's for the day job... We did get to see some sights, here's cars and coffee attendees on April 17th..

Later that same day we rolled past the car wash from Breaking Bad fame...

Robert

-

05-05-2021 09:45 AM #1614

The following weekend we ventured to Moriarity NM to the Lewis Antique Auto and Toy Museum. Heaven on earth...

The inside stuff....

a 427-8V powered 57 T-bird

Some of the treasures outside....

Give me the old stuff over the new...

Alas, all of these goodies were part of the museum and not for sale. We did spend about 4 hours there taking in the sights, even still...Robert

-

05-05-2021 09:56 AM #1615

Love the diverse dislay of cars spanning the decades! Thanks for sharing"  "No matter where you go, there you are!" Steve.

"No matter where you go, there you are!" Steve.

-

05-05-2021 06:28 PM #1616

That is fantastic! I got to put some of this stuff on my to-do list when Kari and I make our big trip with Rita!Seth

God cannot give us a happiness and peace apart from Himself, because it is not there. There is no such thing. C.S.Lewis

-

05-06-2021 07:29 AM #1617

- Join Date

- Apr 2011

- Location

- Prairie City

- Car Year, Make, Model: 40 Ford Deluxe, 68 Corvette, 72&76 K30

- Posts

- 7,301

- Blog Entries

- 1

Very nice trip there! That museum has a lot of awesome stuff outside. Too bad none of that is for sale. Definitely a lot of cool projects there! Did you happen to take any pics of the black split bumper camaro at the cars and coffee event? The Breaking Bad car, that is neat. I was surprised how good that show was. My father in law got me started watching it and I was sad when it ended.

.Ryan

1940 Ford Deluxe Tudor 354 Hemi 46RH Electric Blue w/multi-color flames, Ford 9" Residing in multiple pieces

1968 Corvette Coupe 5.9 Cummins Drag Car 11.43@130mph No stall leaving the line with 1250 rpm's and poor 2.2 60'

1972 Chevy K30 Longhorn P-pumped 24v Compound Turbos 47RH Just another money pit

1971 Camaro RS 5.3 BTR Stage 3 cam, SuperT10

Tire Sizes

-

05-06-2021 09:58 AM #1618

Thanks for all the pics! Way Cool museum too. I'll have to visit it when I'm out there later this year.

-

05-06-2021 10:21 AM #1619

-

05-13-2021 06:29 AM #1620

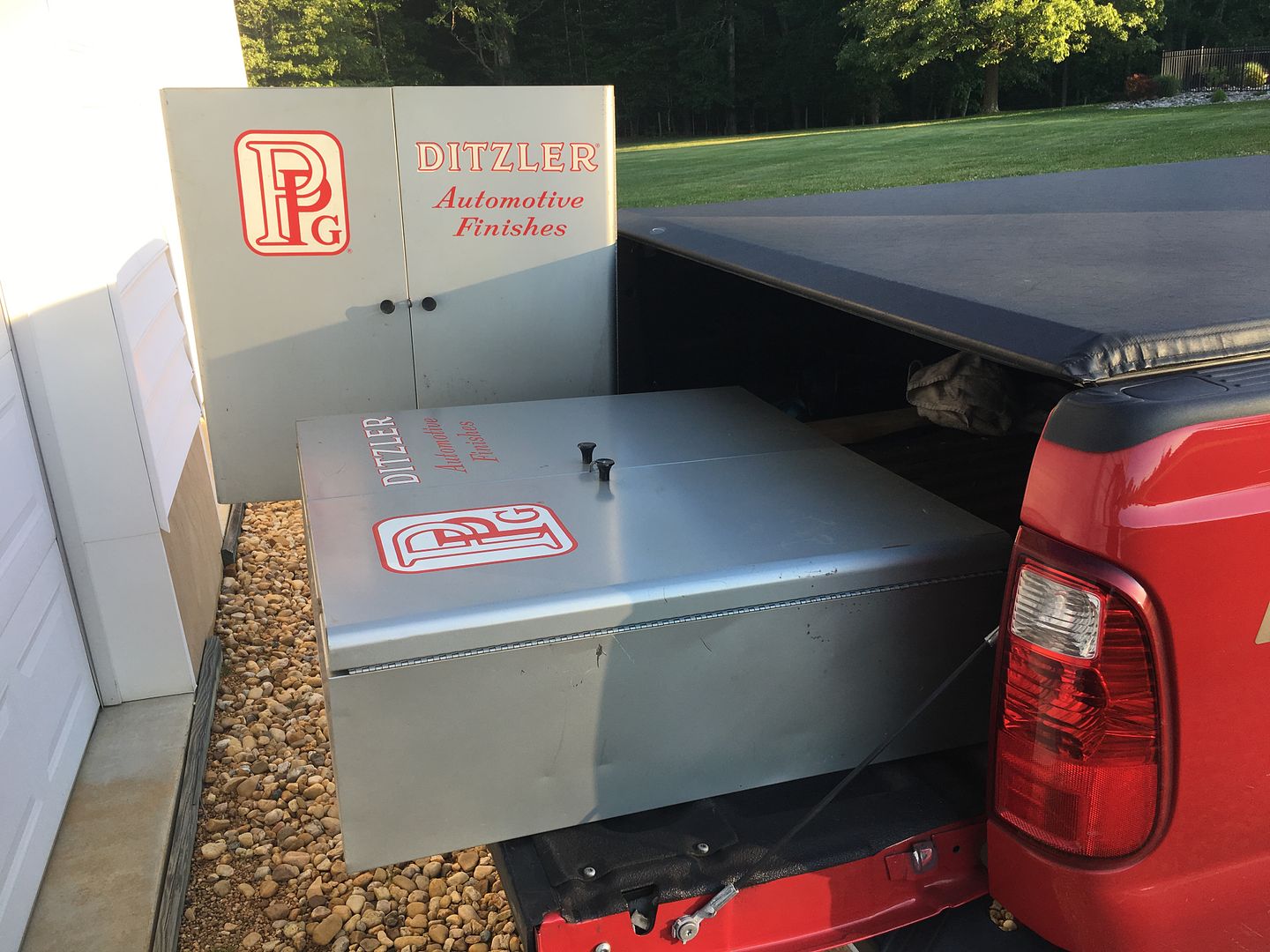

This past Saturday I went to the Jalopyrama show, held at the Talbot County Community Center in Easton, MD. I made a stop off at the parking lot of the Double T Diner in Parole, MD first though, had to finalize an online purchase of these two gems...

Should be some good overflow storage for the Lennox dies.. Here are some of the pictures from the show.. The Willys Woodie is a one of 6 made.

Cody Walls had two cars there in bare steel, badass to say the least. The Buick has been sectioned and roof pancaked, the 32 is heavily channeled.

This show is always a must see, and this year did not disappoint..Robert

3390Likes

3390Likes

LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote

Right after I posted yesterday it was down again, I don't think it's getting better.

Where is everybody?