Thread: 55 Wagon Progress

-

06-08-2014 09:43 PM #226

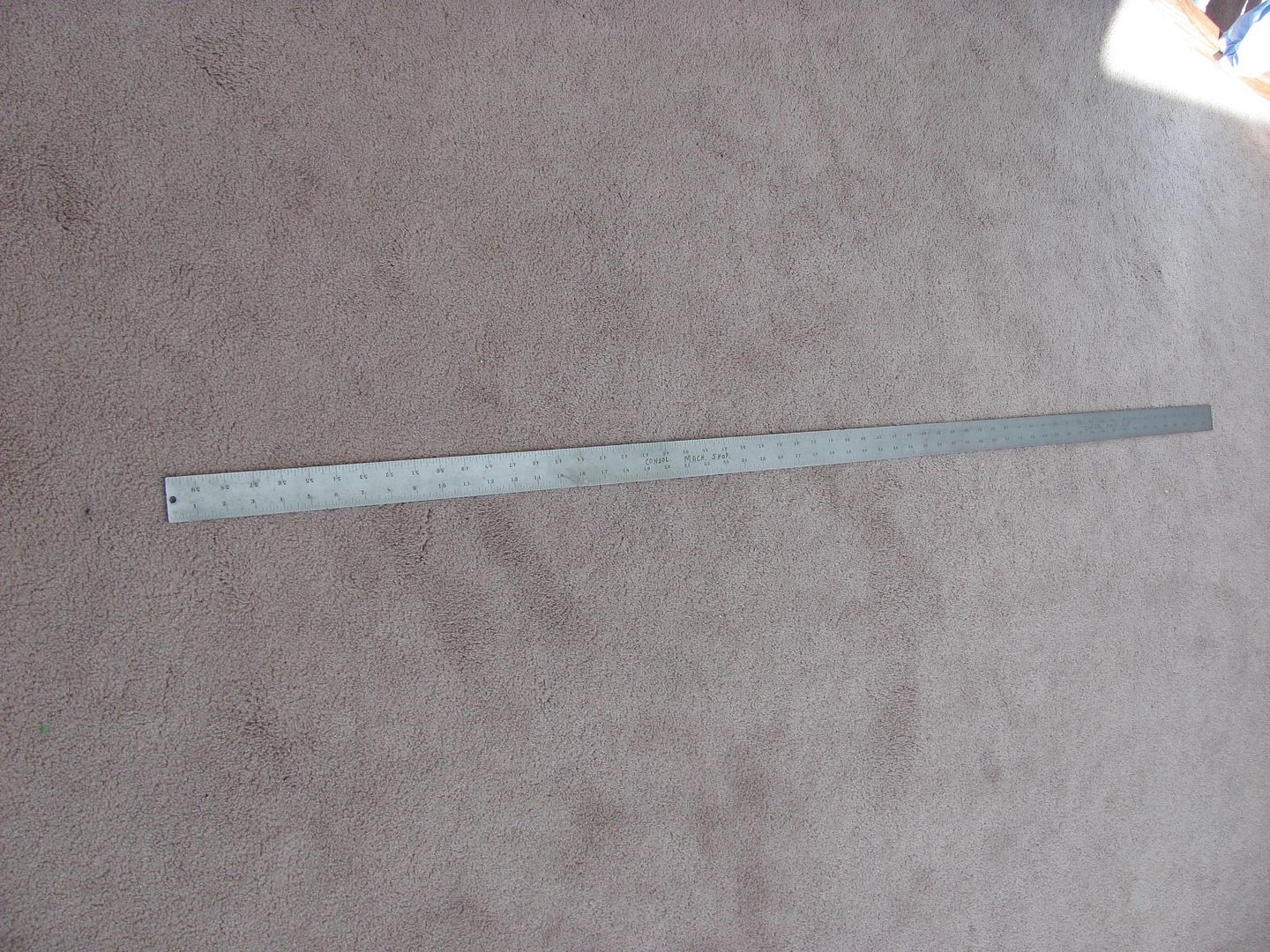

A few months ago, I had bought a 60" Starrett rule.

One of the first things I checked with it was the vertical weld that joined the 4 door NOS quarter on the drivers side of the 55. Previous to this the largest rule I had was a 24", which did not show the deflection as well. When the 60" rule spanned the joint, it showed a pronounced high spot at the vertical weld instead of the gradual crown that the panel should have. I'm not one to overload something with bondo to cover up something like this, so the vertical weld as well as part of the horizontal was sliced open to re-adjust the panel and get the correct contour.

After the slicing was complete, despite the panels coming together slightly, the gap was slightly wider than the first time welded. The butt weld clamps did not work all that well in keeping the panels where they needed to be, and after about the third time of the square peg falling out of the hole, I made a slight modification to better keep the peg from falling out. About one third the way down, the peg was punched on all four sides to keep from falling out.

Although I didn't get pictures of this part, the modified clamp worked especially well in gapping the horizontal weld joint to better fit the profile template for the crown of the panel. Basically with the peg no longer falling out, the portion of the butt weld clamp shown above was used to pull out on the panel until it filled the profile template, then the panels were tacked at that point. Move another couple inches, repeat. This got the vertical crown back where it should be. This was process was repeated for the vertical weld to correct the horizontal crown along the length of the quarter, checking across the vertical seam with the 60" rule. This picture was taken afterwards with the smaller rule so I could hold all the components and the camera, but gives an idea how the "partial clamp" was used to get the panel's crown correct.

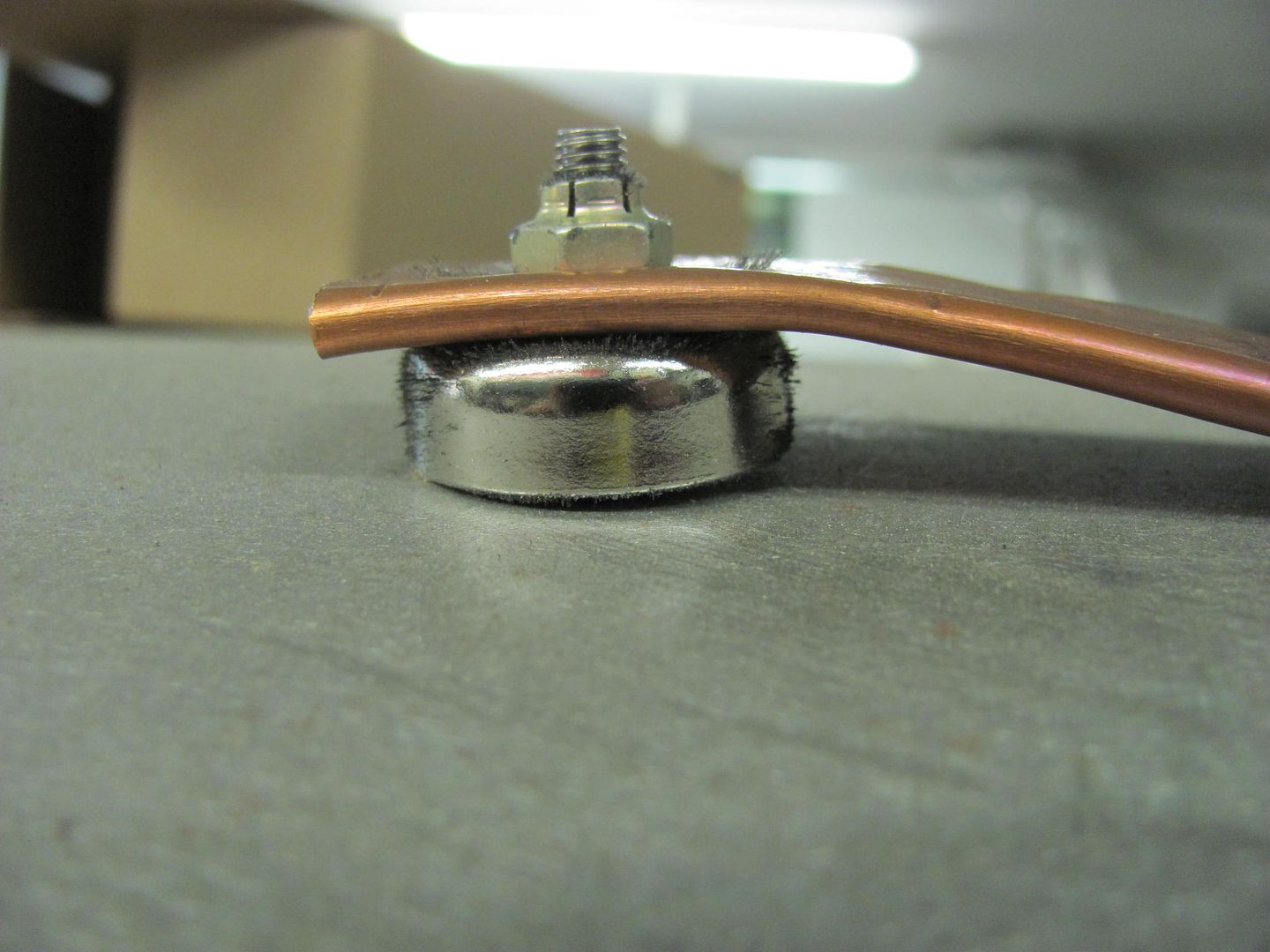

I don't typically used gaps in welding panels, was kinda forced into this to get the crown corrected, so I needed to make a copper backing tool. I had some rare earth magnets so I used one along with some flattened copper pipe. Note the magnet is ever so slightly raised to insure the copper is pulled good and snug to the panel..

Each use will tend to leave the copper soot covered, so I used a welding brush to clean the copper between each weld.

Welds all complete, just a few left to planish and dress, then some panel bumping and we should have one more thing crossed off the list..

Robert

-

Advertising

- Google Adsense

- REGISTERED USERS DO NOT SEE THIS AD

-

06-09-2014 05:38 AM #227

Now that's Master Metalcrafting! I'd say 99/100 would have hit that panel with a skim coat of filler, sanded it smooth and shot it with Hi-Build primer.Roger

Enjoy the little things in life, and you may look back one day and realize that they were really the BIG things.

-

06-09-2014 05:55 AM #228

-

06-09-2014 06:02 AM #229

I use to wonder what all the differences were between a $20K car and a $150K car. After years of building things I know I still lack the integrity, I would have filled and moved on. One day perhaps I will get myself to find that zone consistently. Great post! It has been like reading an advanced Auto-body text book, only with more information.The truth is incontrovertible. Malice may attack it, ignorance may deride it, but in the end, there it is.

Winston Churchill

-

06-09-2014 06:46 AM #230

I like the magnet on the copper that's a GREAT idea. I wind up proping something on the inside or get someone to hold it Again great idea ThanksCharlie

Lovin' what I do and doing what I love

Some guys can fix broken NO ONE can fix STUPID

W8AMR

http://fishertrains94.webs.com/

Christian in training

-

06-09-2014 10:03 AM #231

Very nice work sir!"  "No matter where you go, there you are!" Steve.

"No matter where you go, there you are!" Steve.

-

06-13-2014 05:23 AM #232

Thanks for the comments guys. Charlie, that was a rare earth magnet, super strong. I'm sure one made for a cabinet door at the local hardware store would work equally as well.

Back to some finish work on the driver's quarter, we do have a few low spots to address.

Where the wheelwell and rearward offers quite spacious accommodation for hammer work within the quarter, the window area forward of the rear wheel does not fall in the same category. So as much as it pains me, one of the Snap On body hammers was given a top chop..

Yeah, this will do the trick...

For a dolly on the outside, the small shot bag is used to promote small, controllable stretches.

After the hammer work, placing the rule at a slight angle across the seam to use as a profile gauge, the area is much better than before.

This should hold this spot until paint. For now, another item checked off the list...

Moving to the other side, got about half of the quarter's weld seam ground flush on the outside, more to come.

Robert

-

06-13-2014 06:01 AM #233

Thanks for adding to your day's work all the detailed photos and posts.The truth is incontrovertible. Malice may attack it, ignorance may deride it, but in the end, there it is.

Winston Churchill

-

06-13-2014 02:12 PM #234

- Join Date

- Apr 2011

- Location

- Prairie City

- Car Year, Make, Model: 40 Ford Deluxe, 68 Corvette, 72&76 K30

- Posts

- 7,301

- Blog Entries

- 1

More great work sir! You make it look easy!Ryan

1940 Ford Deluxe Tudor 354 Hemi 46RH Electric Blue w/multi-color flames, Ford 9" Residing in multiple pieces

1968 Corvette Coupe 5.9 Cummins Drag Car 11.43@130mph No stall leaving the line with 1250 rpm's and poor 2.2 60'

1972 Chevy K30 Longhorn P-pumped 24v Compound Turbos 47RH Just another money pit

1971 Camaro RS 5.3 BTR Stage 3 cam, SuperT10

Tire Sizes

-

06-13-2014 07:05 PM #235

Thank You Robert. It is appreciated!

-

06-14-2014 05:04 AM #236

Ya might consider having some harbor freight hammers for future specialty tools, I know cutting on that snap-on hurt you almost as much as it hurt the hammer!.

Education is expensive. Keep that in mind, and you'll never be terribly upset when a project goes awry.

EG

-

06-14-2014 08:29 AM #237

Just a guess here but I think the words harbor freight are not heard in Roberts' shop.

Jack.www.clubhotrod.com/forums/showthread.php?t=44081

-

06-14-2014 11:59 AM #238

Nothing that I've bought...

Robert

-

06-14-2014 03:41 PM #239

Everyone has a drawer where they keep there "special tools"Charlie

Lovin' what I do and doing what I love

Some guys can fix broken NO ONE can fix STUPID

W8AMR

http://fishertrains94.webs.com/

Christian in training

-

06-15-2014 12:17 PM #240

Yup! Got my retactable antennae magnet in there, and a wierd little snaking flashlight"  "No matter where you go, there you are!" Steve.

"No matter where you go, there you are!" Steve.

3390Likes

3390Likes

LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks Reply With Quote

Reply With Quote

Right after I posted yesterday it was down again, I don't think it's getting better.

Where is everybody?