Thread: 55 Wagon Progress

Hybrid View

-

09-10-2016 06:27 PM #1

Thanks for the comments guys. We had quite a few conversations over the work done on the wagon, looked at other's rides for onsite suggestions, a good time overall.

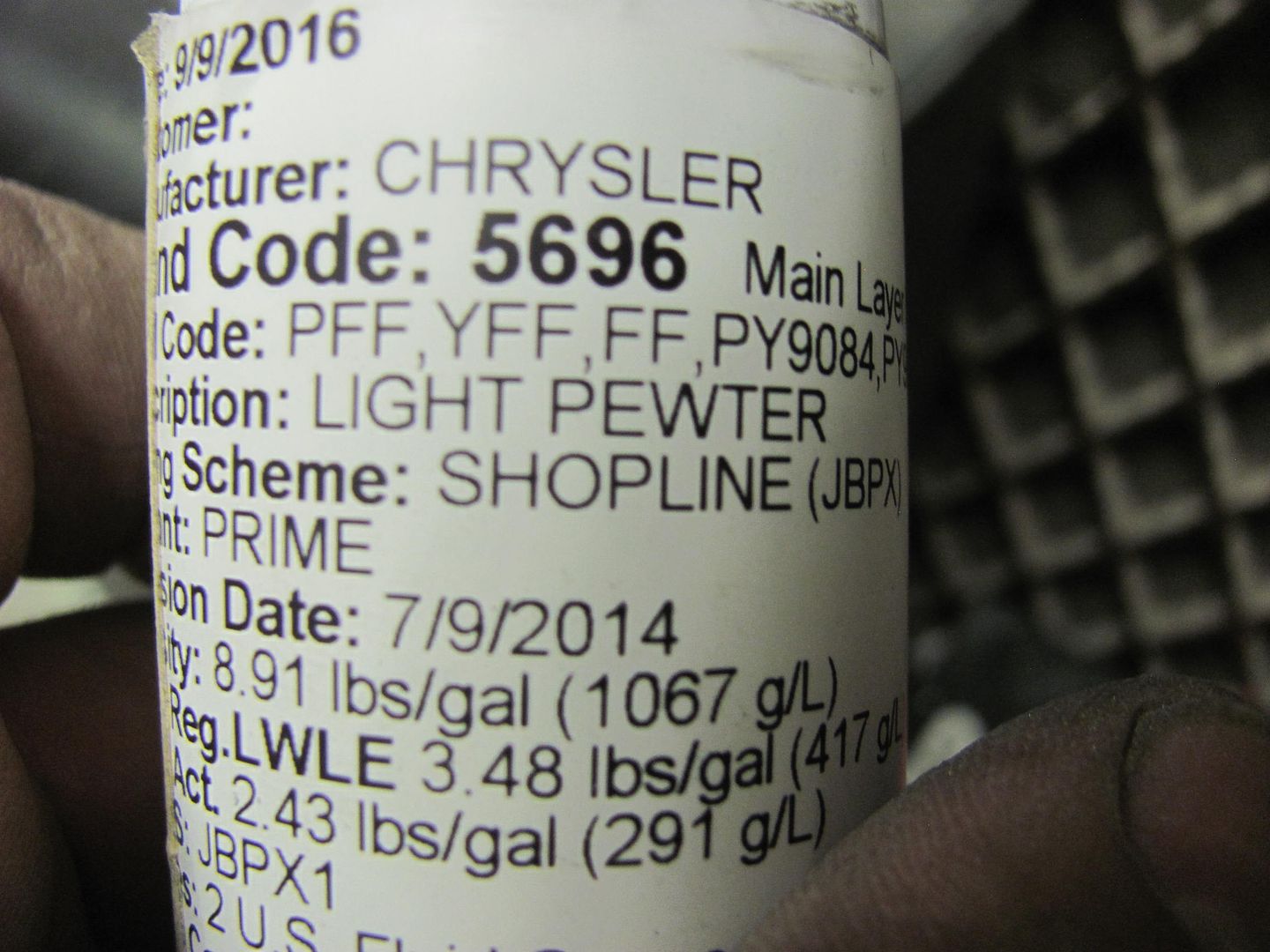

Today was more blocking on the 55, and moving forward to get it ready for the Linex that will go on the bottom side. We need to get seat brackets complete and welded into the floor, finish epoxy prime on cavities (rocker and inner quarter), install wheel houses, etc. Yesterday was a road trip to get a paint sample and other paint supplies. here's the proposed color for above the quarter...

With the H/K Organic Green Kandy basecoat on the quarters down. To better get a feel for the test sprayout of the Kandy, a panel was made to simulate the top of the quarter, so we can better see the effects in the sunlight...

Next, epoxy in the cavities. I had looked at cavity spraying wands and the like, and did not care for what was available. So lets get basic, after all it is unseen when complete..

This area doesn't have to be pretty, so picked up this goodie at the local hardware store..

.....which should get enough on the inner quarter to seal things up..

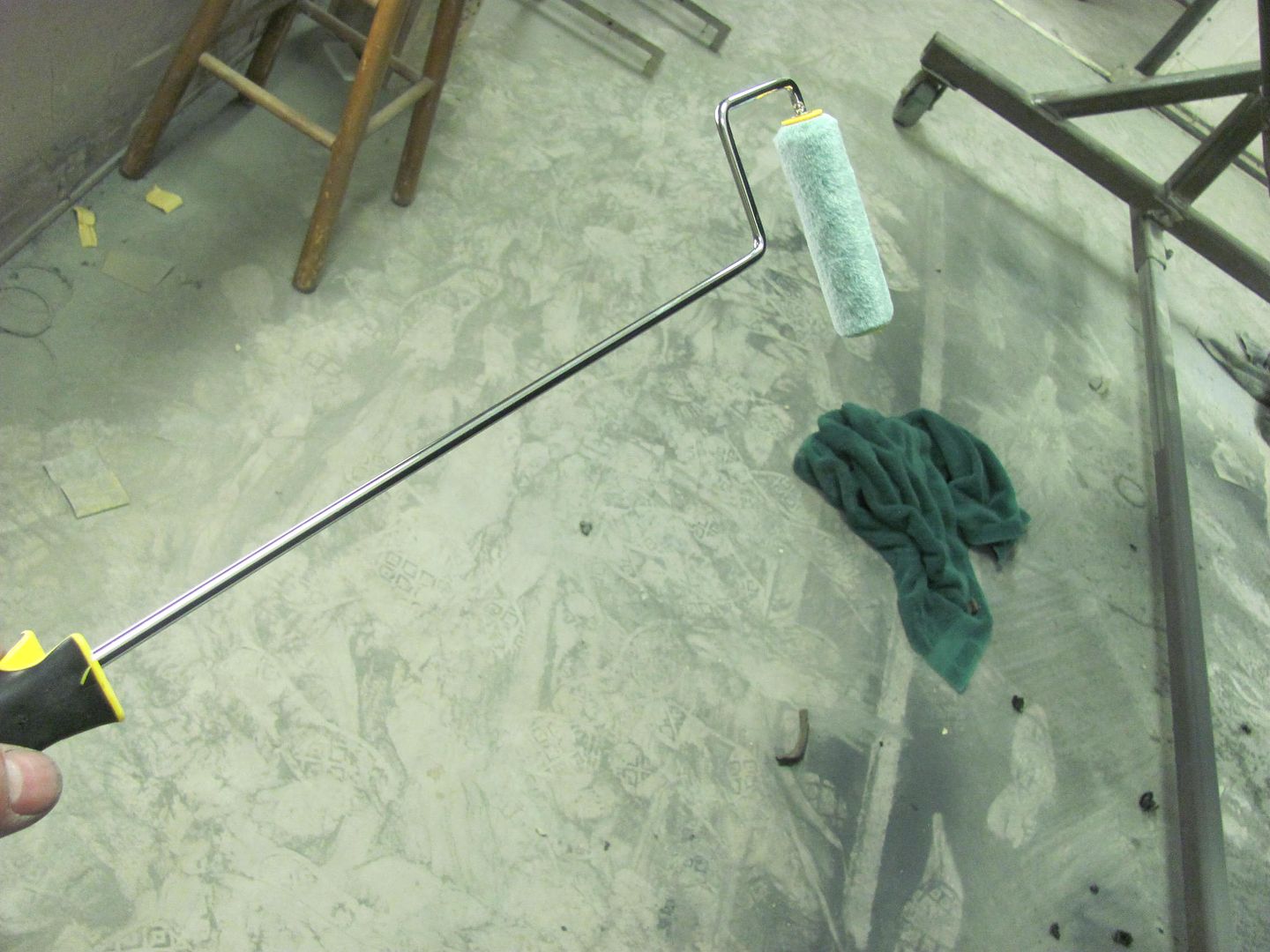

For the rocker, needed a bit more reach, both to scuff things up and roll on some paint. Here's the new multi-tool, with a 4' lift kit.

Scuffing attachment

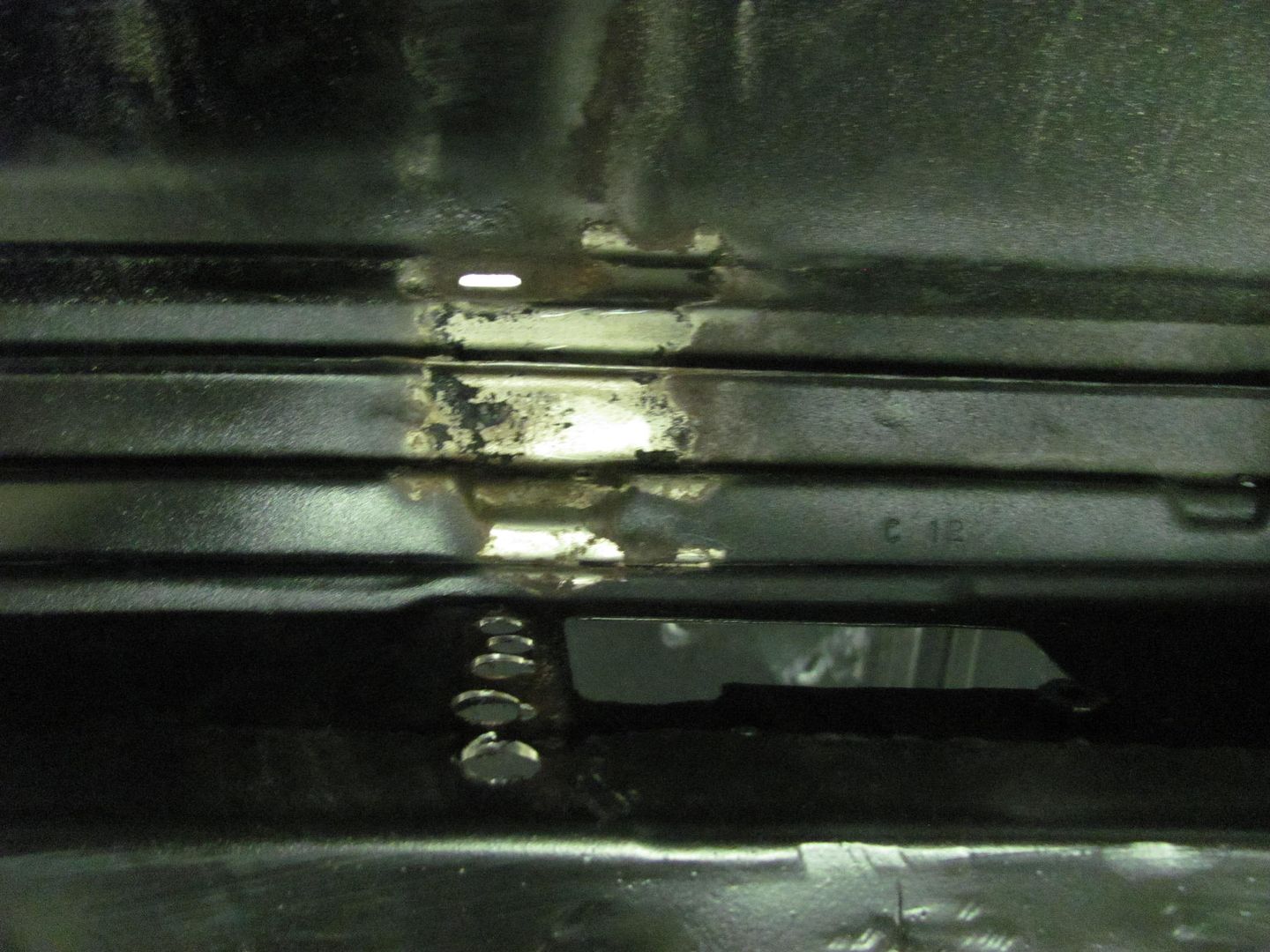

Target area..

These dividers sit above the wheelwells inside the top of the quarter, and a bottom flange serves as a welding anchor for the top of the wheelwell. If they both had a bottom flange..

On top of those was a nice foam seal, which also served to trap water and cause one of our pits in the original quarter that we removed.

So the thought is to replace these with new ones made of 16 gauge, using a bulb seal at the top for less water absorption/retention...

With these now removed, you can see the still bare 1955 sheet metal that we'll also get covered with epoxy prior to installing the new brackets..

After all this fun, we loaded up one of the Biederman fenders and took it over to Saufley Sandblasting to get a quote on those. We'll get all the parts blasted individually, then sealed in epoxy primer, then assembled. After assembly, one more dose of Epoxy and they're off to the painter..Robert

-

09-12-2016 03:00 PM #2

- Join Date

- Apr 2011

- Location

- Prairie City

- Car Year, Make, Model: 40 Ford Deluxe, 68 Corvette, 72&76 K30

- Posts

- 7,301

- Blog Entries

- 1

More awesome work. Your tools to get in the quarter should work very nicely.Ryan

1940 Ford Deluxe Tudor 354 Hemi 46RH Electric Blue w/multi-color flames, Ford 9" Residing in multiple pieces

1968 Corvette Coupe 5.9 Cummins Drag Car 11.43@130mph No stall leaving the line with 1250 rpm's and poor 2.2 60'

1972 Chevy K30 Longhorn P-pumped 24v Compound Turbos 47RH Just another money pit

1971 Camaro RS 5.3 BTR Stage 3 cam, SuperT10

Tire Sizes

-

09-17-2016 07:59 PM #3

Working today on fitting up the wheel wells. The front half is re-popped and uses the same part as the sedans, the rear part is not available. Fitting the front, notice the right lower corner (as shown) tapers up with less overlap for plug/spot welding.

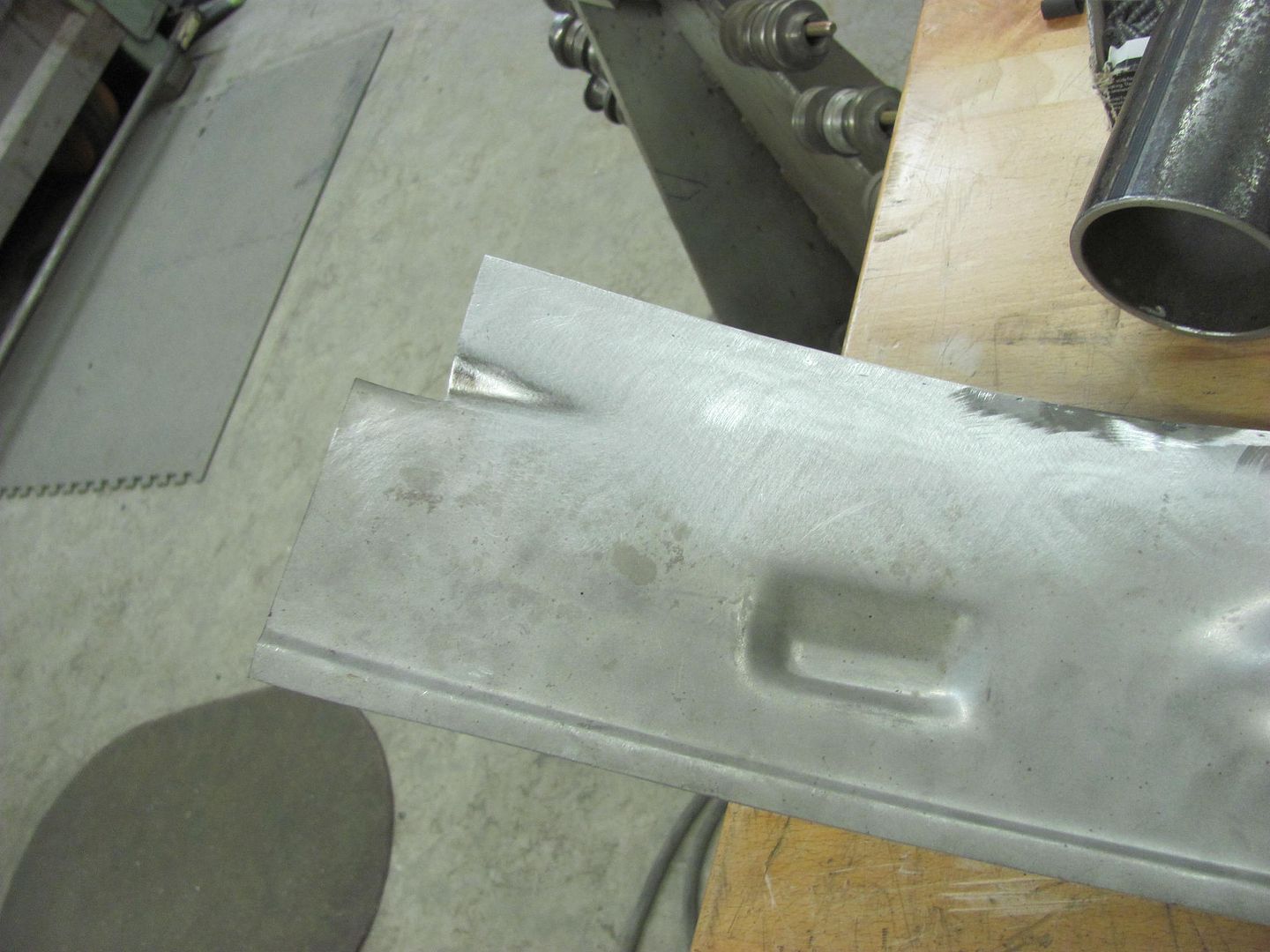

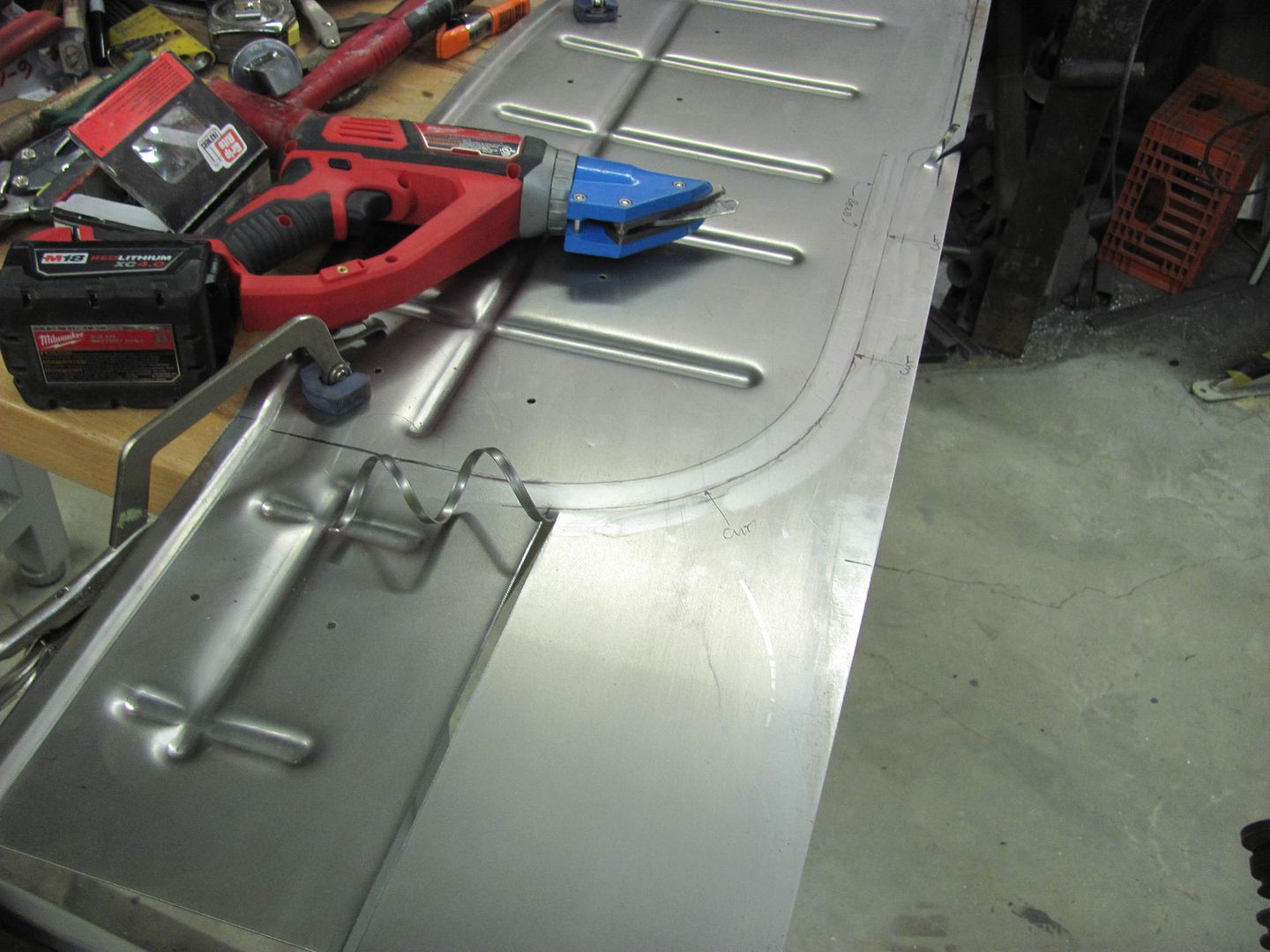

The rear section is NOT available in reproduction, and the notch you see there is for routing the fuel fill on a wagon tank. We've switched to a sedan tank to make room for dual exhaust, and given the widened wheel tubs and tires being used, no need in leaving such a gaping hole. So new parts it is.. The lower flap I'm holding is a separate piece that is spot welded on. In an effort to minimize moisture traps/rust generators in the future, we'll make this in one piece.

To fix our front repop, a piece of 18 gauge is TIG welded to give us a square corner...

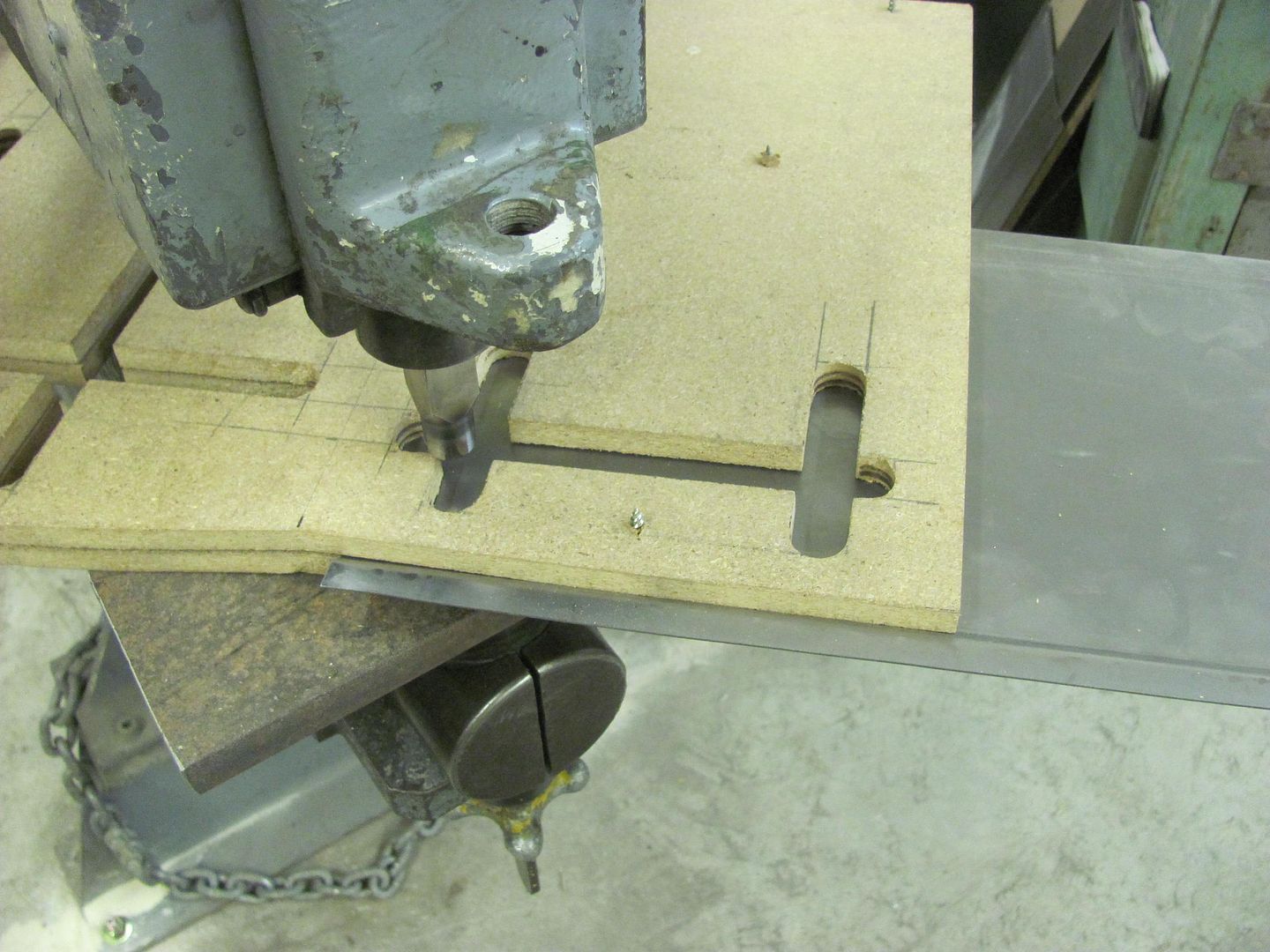

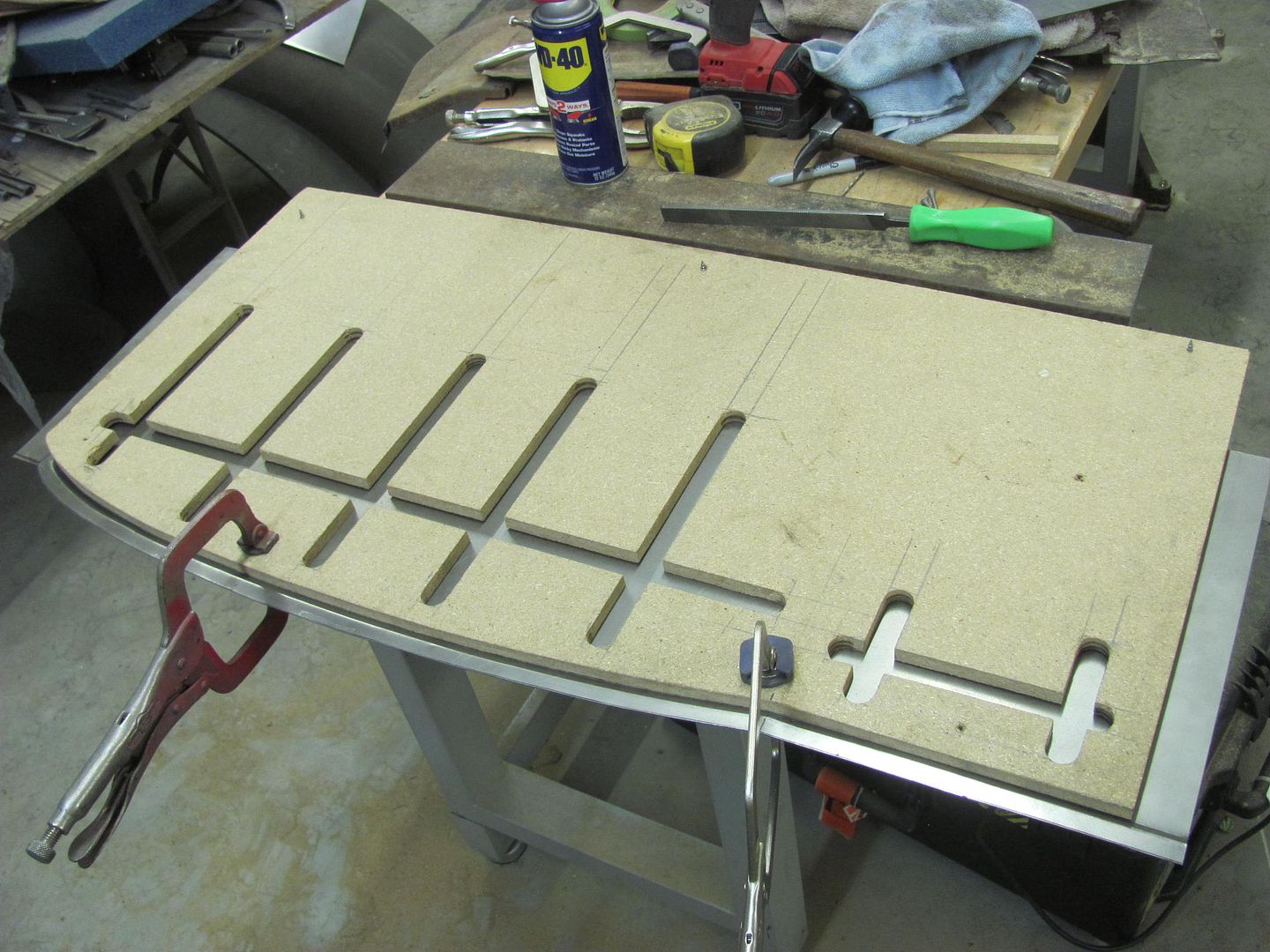

To make the new piece for the rear, we'll need a method to add beads that cross each other. This will entail a small table to use on the Lennox, an upper punch, and two pieces of matched MDF. Slots will be cut into the MDF, the top used as a guide for the punch, the bottom acts as our bottom die as it "rests" on the table..

The table will be supported in the lower tool holder using a 3/4 shank. The end is turned down to 1/2" to mate into a 1/2" hole in the 4 x 12 table, which is then plug welded.

For an upper punch, we'll use some 3/4 oil hardening 4140, making it less pointed than the original just in case we want to use it for something besides the 55.

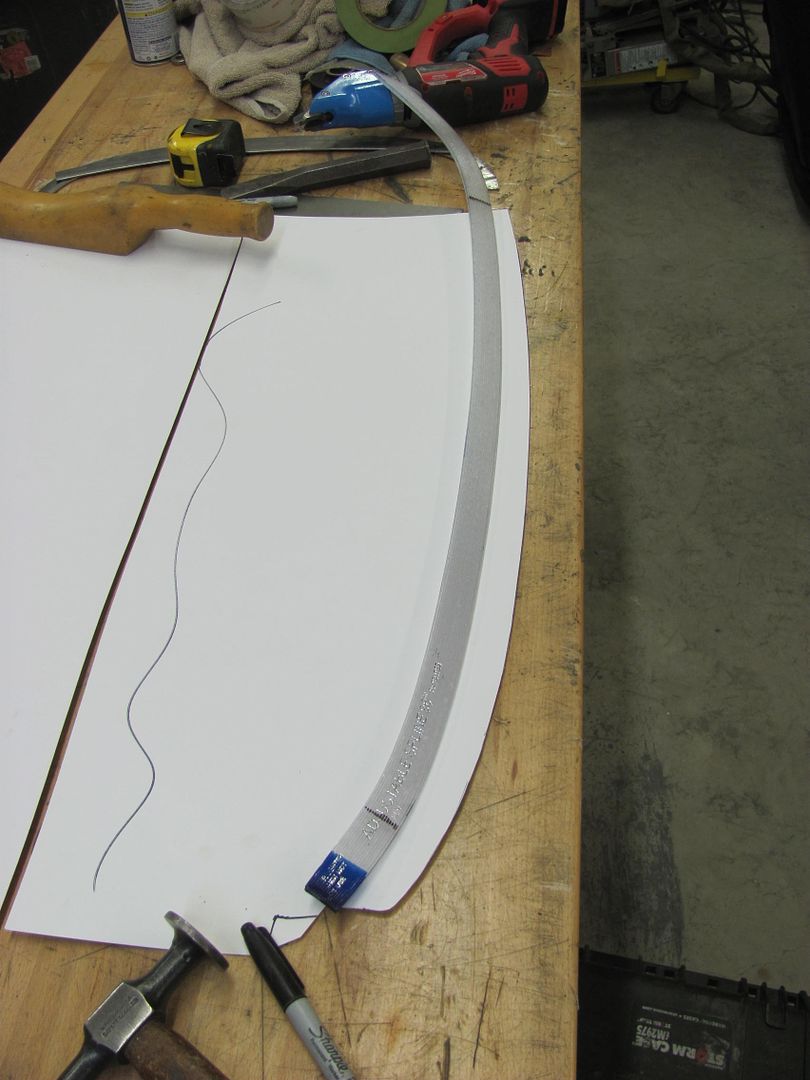

For a bead guide we first need to get a good template of the inside of the quarter. The adjustable spline comes in handy...

MDF is screwed together and then the edge profile cut..

Cutting our bead pattern..

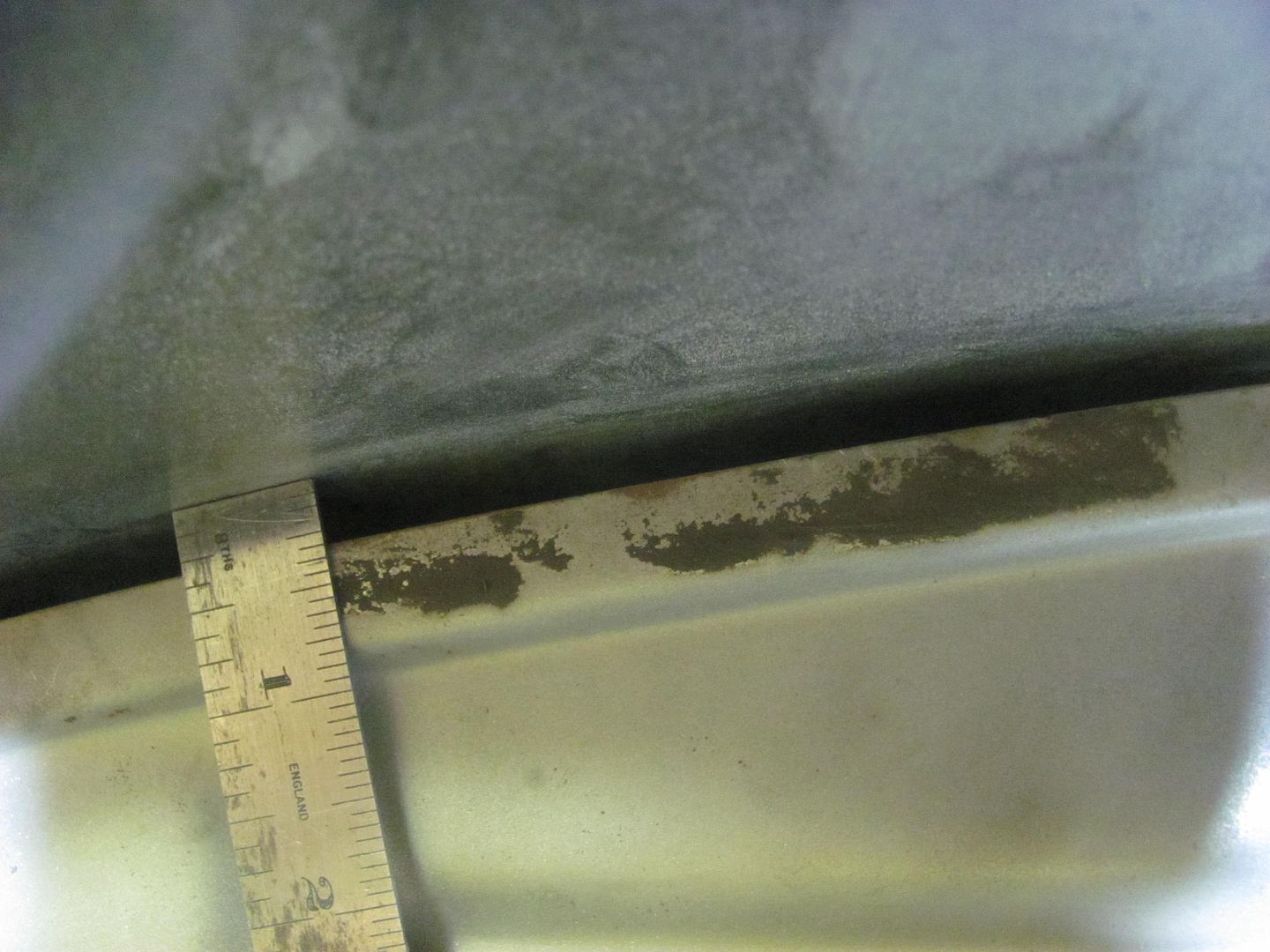

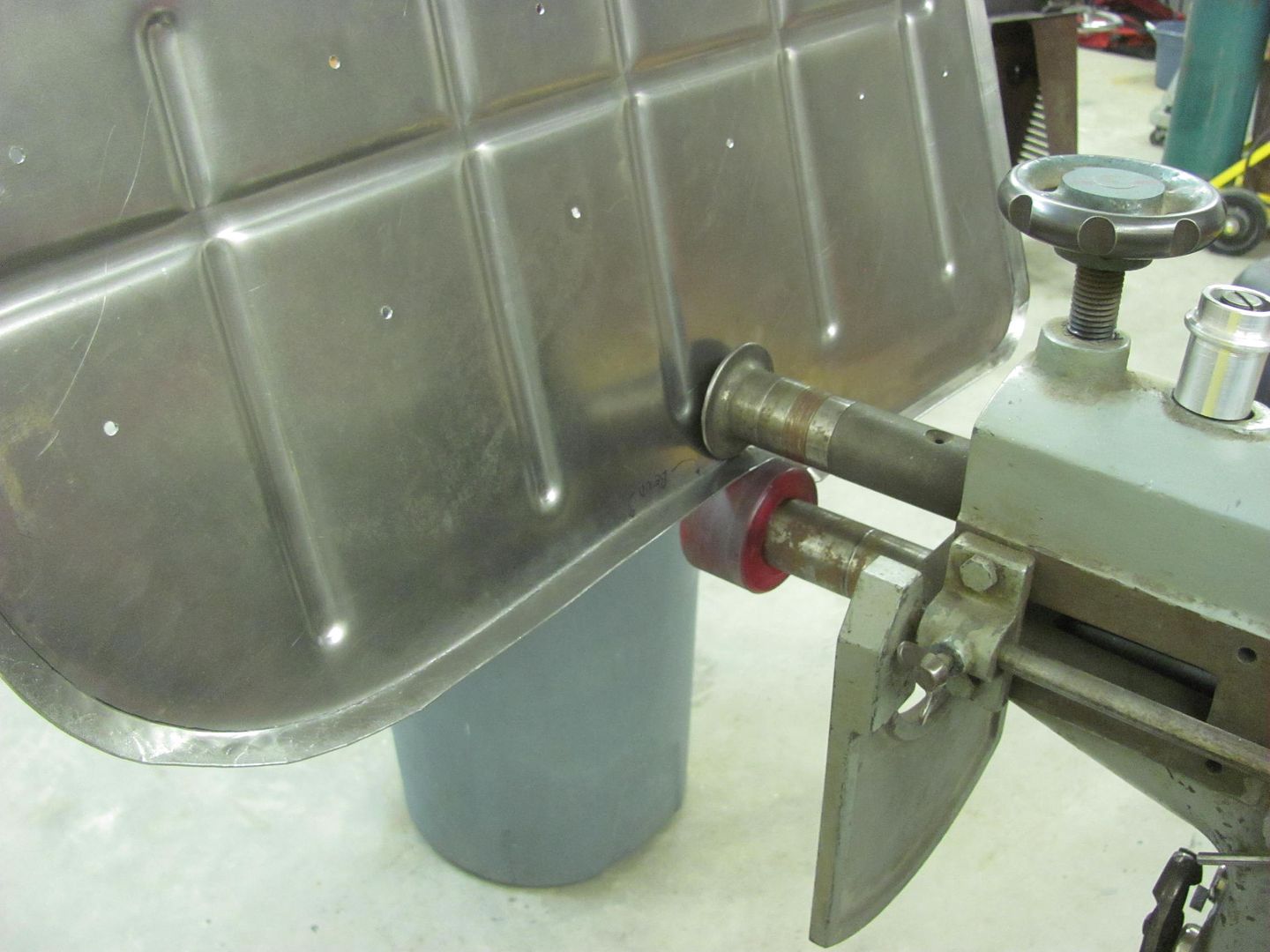

The offset of the original for the quarter seal is added using a tipping die in the Lennox, slight modification on the backstop for the correct width..

New matches the repop....

This seal will be used against the inside of the quarter..

Running a test pattern... The table height is adjusted to set the punch depth...

All clamped up, ready to go. Kyle has already left for the day so we'll finish up next time..

Last edited by MP&C; 09-21-2016 at 06:54 AM.

Robert

-

09-18-2016 02:47 AM #4

I know we always say thank you for stopping to get pictures for us, and it really must slow down your productivity!

But, from one of the "students"... Thank You! I really do appreciate the education and it's enjoyable watching a master work.

Tell Kyle the "class" says Hi... lol..

-

09-20-2016 08:32 PM #5

Thanks!

Made our table slightly larger to better hold the panel level for punch depth consistency..

More holes for screws added to keep things snug

A few holes to fill, we'll get the other side done and weld them all in one sitting.

Motion picture version:

https://www.youtube.com/watch?v=KCIv27b4dPs

.Robert

-

09-23-2016 10:49 AM #6

Last night we used the poster board template to check the fit of our pattern to the passenger side. Only a slight shave in the middle for a good snug fit. Then we test fit the repop front section of wheel well, which was horrendous. if we were to trim it to fit there wouldn't be enough step flange left over for the seal. So, Kyle added a 1/2" strip of 18 gauge cold rolled to the outside so we will have enough to trim for a proper fit. Still needs to add that corner on this side as well.

https://www.youtube.com/watch?v=DNiSM9Oyp2s

While he was welding away, I trimmed the second panel for the passenger rear wheel well, used the Lennox with the tipping die to add the step flange for the seal, and got it prepped for the bead detail work, which we'll get to on Saturday.Robert

-

09-23-2016 01:14 PM #7

I wish I could tig as fast as Kyle! LOL...

-

09-23-2016 02:51 PM #8

Me too. He just runs circles around me..

Robert

-

09-23-2016 03:31 PM #9

- Join Date

- Apr 2011

- Location

- Prairie City

- Car Year, Make, Model: 40 Ford Deluxe, 68 Corvette, 72&76 K30

- Posts

- 7,301

- Blog Entries

- 1

More great work you 2!Ryan

1940 Ford Deluxe Tudor 354 Hemi 46RH Electric Blue w/multi-color flames, Ford 9" Residing in multiple pieces

1968 Corvette Coupe 5.9 Cummins Drag Car 11.43@130mph No stall leaving the line with 1250 rpm's and poor 2.2 60'

1972 Chevy K30 Longhorn P-pumped 24v Compound Turbos 47RH Just another money pit

1971 Camaro RS 5.3 BTR Stage 3 cam, SuperT10

Tire Sizes

-

09-24-2016 07:00 PM #10

Thanks Ryan!

Here's a test fit of the reproduction wheel well for the 55, this is the front section. Note the poor fit to the rear side of the quarter panel. I don't know if these are an EXACT reproduction of OEM, but have heard others having similar "gaping hole" issues with their original cars.

This is the driver's side:

video version....

https://www.youtube.com/watch?v=WiSaQXkkowc

This is the passenger side we modified Thursday, adding a 1/2" filler strip and then trimming to fit to the quarter panel....

.......and shown here with seal in place...

Here Kyle is adding the 1/2" filler strip to the driver's side reproduction wheel well.

https://www.youtube.com/watch?v=penIygidVUc

With the rear section not available in reproduction (blessing in disguise), here is the final layout and trim of our version..

Flanges are tipped using the Fasti swaging machine..

Test fit of the driver's side wheel wells. The front reproduction piece has the filler strip added but still needs trimming, the rear section is a much better fit than what came out from the factory..

Video version:

https://www.youtube.com/watch?v=9BvNqdKQf3U

Once the front section has been trimmed for proper fit, we will butt weld the front and rear section together to eliminate another overlap rust trap.Robert

-

09-26-2016 02:05 PM #11

- Join Date

- Apr 2011

- Location

- Prairie City

- Car Year, Make, Model: 40 Ford Deluxe, 68 Corvette, 72&76 K30

- Posts

- 7,301

- Blog Entries

- 1

More great work and attention to detail no one will see. But, that will help keep that car around for another 100 years or more!Ryan

1940 Ford Deluxe Tudor 354 Hemi 46RH Electric Blue w/multi-color flames, Ford 9" Residing in multiple pieces

1968 Corvette Coupe 5.9 Cummins Drag Car 11.43@130mph No stall leaving the line with 1250 rpm's and poor 2.2 60'

1972 Chevy K30 Longhorn P-pumped 24v Compound Turbos 47RH Just another money pit

1971 Camaro RS 5.3 BTR Stage 3 cam, SuperT10

Tire Sizes

-

10-01-2016 08:07 PM #12

Haha, so true. Thanks Ryan.

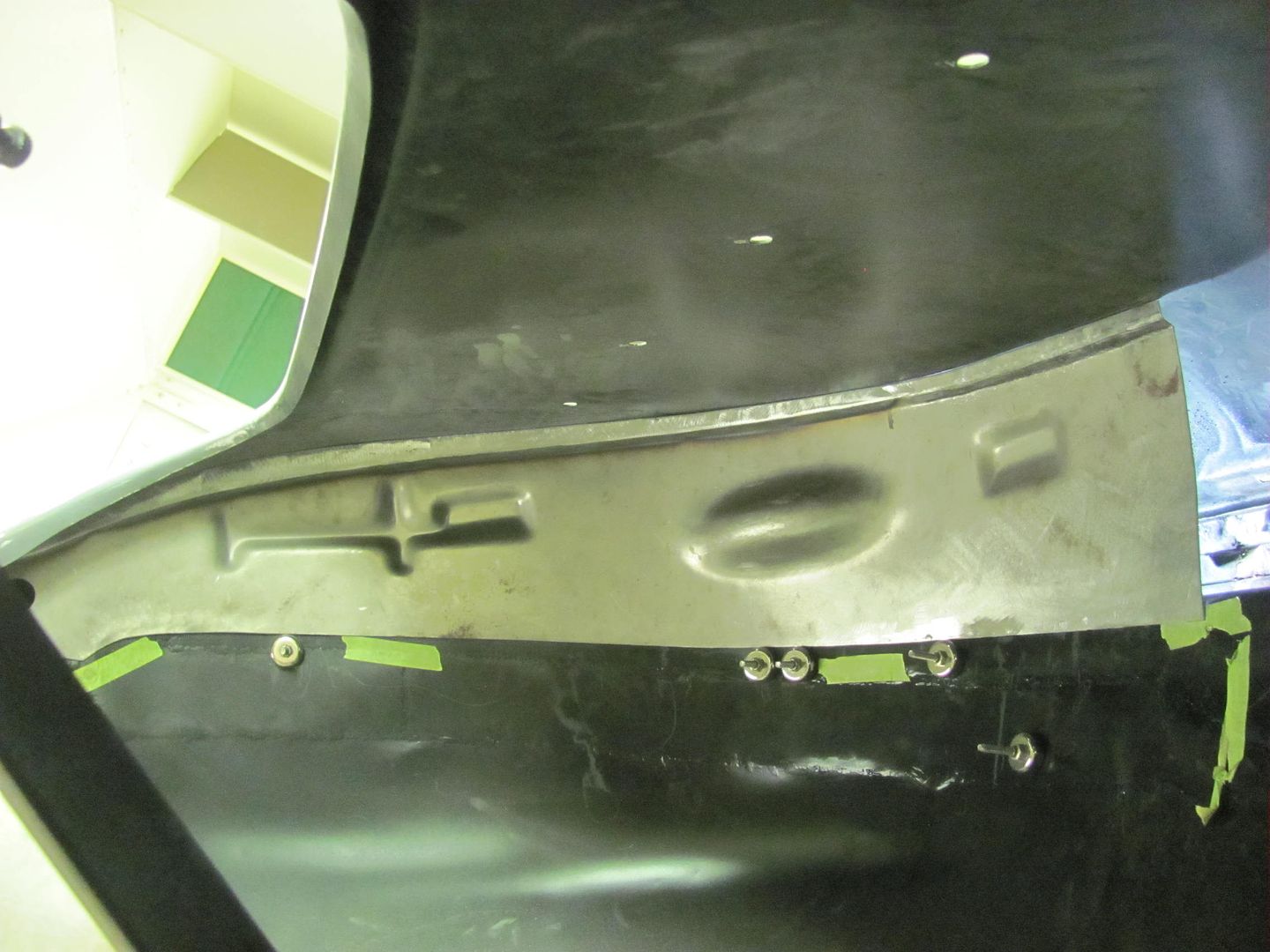

Finishing up on our drivers side wheel well today. The front "modified" reproduction is trimmed and fitted. A light is put behind it to check for gaps...

The baffle that sits above the wheel well is made differently as well, this time using a piece of 16 ga cold rolled steel, and trimmed to fill the void. We left a slight gap that we plan on sealing with seam sealer.

Shown here with bulb seal against the quarter....

The trouble with the factory version of sealing above the baffle is that the expanding foam encapsulates the surrounding area, to include surrounding the slot for trim hardware. It is here that water intrudes, and is held against the quarter causing rust.

Our version will leave this hole unobstructed so that any water intrusion that may occur will pass on through.

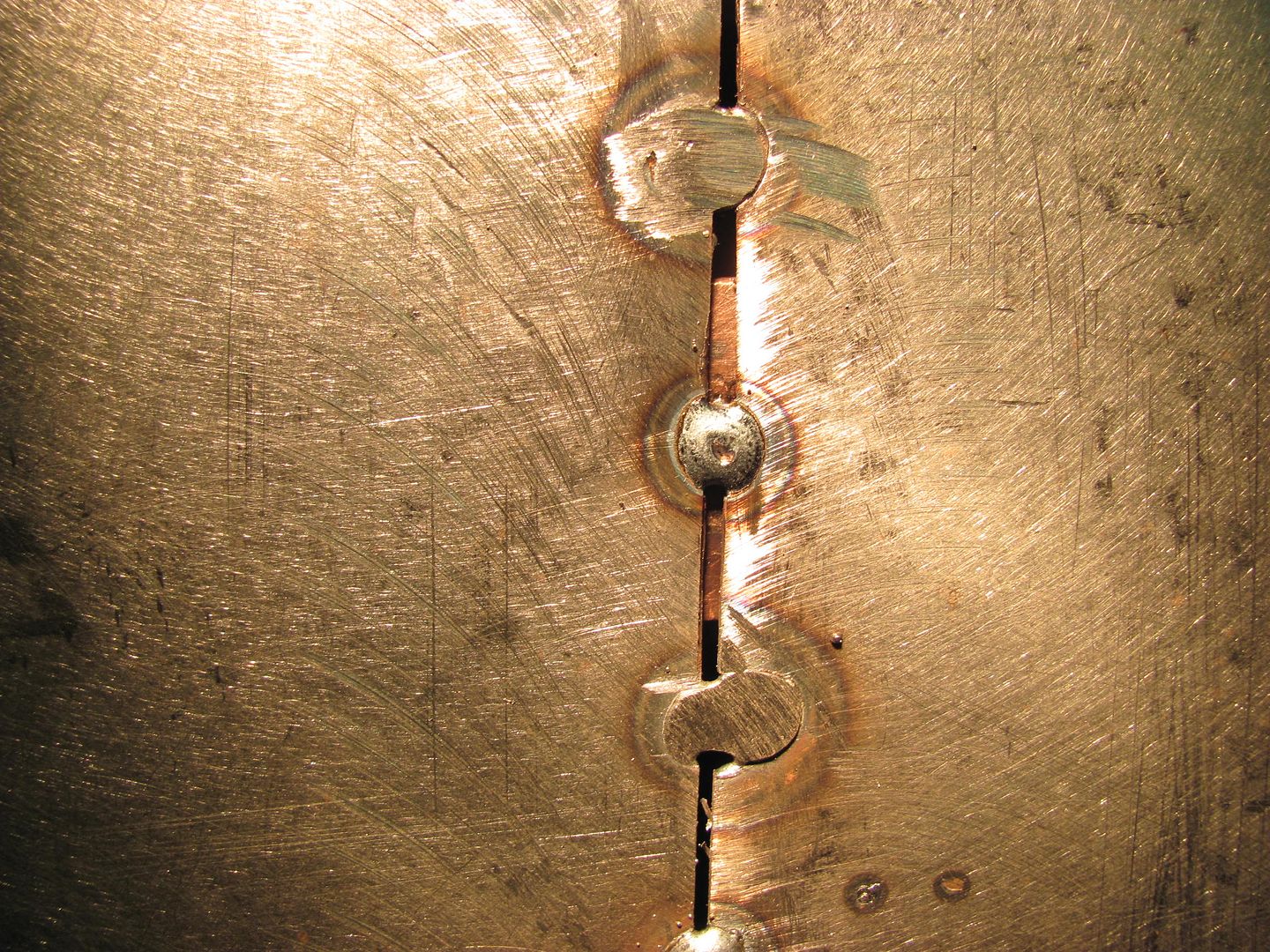

Now to fill in our screw holes that held together the "MDF Sandwich" that we used for beading the panel. A piece of 1/4" thick X 1" copper flat bar is used as a backer, I find it leaves the back side of the weld much cleaner than using flattened copper pipe.

Video version:

https://www.youtube.com/watch?v=H2k5_RqRnzc

With the front and rear sections having been fitted and trimmed for a butt weld, next we tack the panels together with the TIG..

Now we have a one piece wheel well, no overlap joints to trap moisture and start rust, as the originals had done.

One piece wheel well test fitted using the bulb seal....

https://www.youtube.com/watch?v=ViIPhYNsEb0

Moving on to the passenger side, both front and back are trimmed and test fitted. Some minor tweaks and we will be ready to trim for a butt weld and TIG these together next time..

Robert

-

10-02-2016 08:46 AM #13

Thanks Robert for the 1/4" copper backer tip. I've been using just any old piece of copper, usually just a thin piece of scrap lying around.

Jack.www.clubhotrod.com/forums/showthread.php?t=44081

-

10-02-2016 09:15 AM #14

Roger

Enjoy the little things in life, and you may look back one day and realize that they were really the BIG things.

-

10-02-2016 10:33 AM #15

Here's the flattened copper pipe using a rare earth magnet for hands free/clamp free operation..

Shown here as a backer for filling too wide of a gap..

The problem we found was that the back side of the weld, which was against the copper, gets a bit of contamination/porosity.

I've found that the copper buss bar (electrical) does not show this same issue. Not sure if the pipe has elements added to promote solder wetting, or what the issue is. But for the holes welded yesterday using the buss bar, the front and back looked the same. We have since stopped using the copper pipe. When we weld the holes in the passenger side wheel wells I'll have to get some comparison pictures. We also now have a section of the buss bar that's had offset bends added to the ends for attaching magnets where they will remain flush.Last edited by MP&C; 10-02-2016 at 10:41 AM.

Robert

3390Likes

3390Likes

LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks Reply With Quote

Reply With Quote

I'm happy to see it back up, sure hope it lasts.

Back online