Thread: 55 Wagon Progress

Results 1 to 15 of 1865

Threaded View

-

03-28-2021 08:47 PM #11

Thanks gents!!!

Progress from yesterday, while Jared was blocking out some of the window garnish moldings, I worked on the door panel stainless trim to ready them for stud welding. Mike had used the trim repair tool to remove the dings, which were then filed smooth.

The last 65 years had left their mark; we had numerous scratches needing removal as well. We started with 320 grit on the fine pattern palm sander, and progressed our way up to 8000 grit trizact..

This is the final using the 8000 grit, and we'll start the buffing process once the stud welding had been completed..

https://www.youtube.com/watch?v=n5YYWcQgIRg

With the stainless prepped, we turned attention to the window garnishes. They were sprayed with three coats of SPI epoxy.

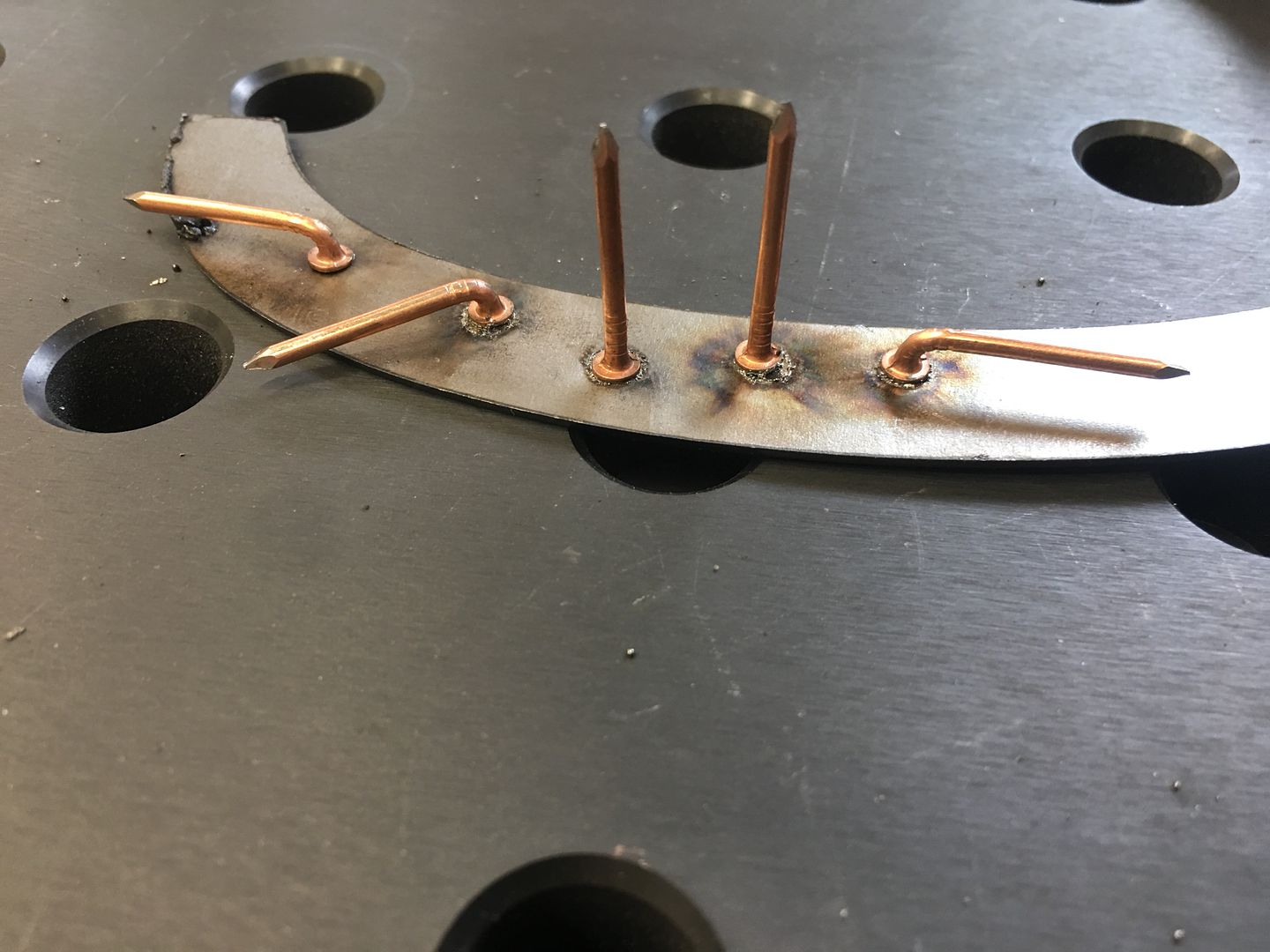

Today we went to A&A Metalworks in Ridge MD to get the studs welded in place. This sample shows the studs, where three have been folded over to a 90. This is how the factory held them onto the door panels as well. Note the back side shows no heat pattern with the Capacitive Discharge welder.

Welding the studs onto the stainless trim...

https://www.youtube.com/watch?v=7WZ25tqOXos

Our results...

https://www.youtube.com/watch?v=YXQCJe1hma8

A test to check the heat the welder introduces into the panel..

https://www.youtube.com/watch?v=DkDRJXstvH4

This shows these welders make a good choice to use where cases of heat sensitivity may be an issue.Robert

3390Likes

3390Likes LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote

I'm happy to see it back up, sure hope it lasts.

Back online