Thread: 55 Wagon Progress

Hybrid View

-

03-20-2021 04:23 AM #1

As I'm flipping through your pictures from the last few posts... my brain is screaming "Are you Nuckin' Futs???"

Cutting on brand new paint? to fit a bumper... it's not even my car or job and my heart is in my throat!

While I would never doubt your skills or talent... dang that was painful to review.. LOL..

-

03-23-2021 11:22 AM #2

Not my favorite back up and punt moment, I have to admit..

So we've started on our wiring, what can go wrong? First item on the list is the interior lights, we had run the wires before the headliner went in. We had installed a second light just behind the rear seat and the plans were to gang it to the front light by putting two wires into a 12 gauge pin in the weatherpack connector. This should be a 5 minute job.

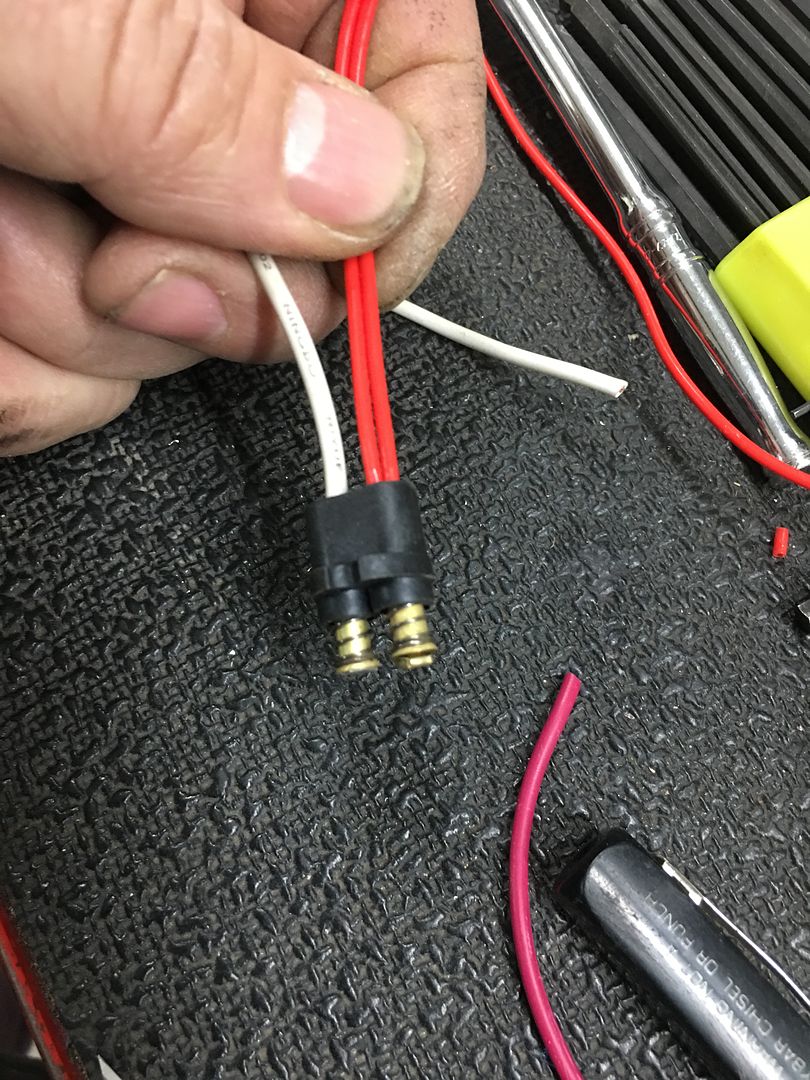

Only the weatherpack connector would not fit inside the void in the ceiling. Since we don't intend on using butt splices, we had tried installing two wires previously into the w-crimp lamp base contacts as shown:

This sample we did using the red Teflon insulation fit inside the brass "tubes" of the lamp base perfectly. But the insulation on AAW wiring is much thicker. Ahhh, the dominoes they do fall. So let's see what we can do to modify the brass tubes to better accept the wiring going in. Our local Ace hardware has a good selection of "model" tubing in aluminum and brass, so with fingers crossed, we picked up the 3/16 size.

The ID measured out to .154, about .010 larger than what the lamp base came with. The outside diameter of the tube was turned down on the lathe to a size that would play nice inside the plastic housing and not bind on the spring.

Some aluminum bar stock was drilled with a tight clearance hole for our new tube, and served as a fixture to swage one end for spring retention. Sorry, missed pictures of some of the details (fire the photographer). The opposite end was swaged after insertion into the housing..

With the tubes now sized for two wires, we got the front light installed. The rear light and its single wires should now be a breeze.

Robert

3390Likes

3390Likes

LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks Reply With Quote

Reply With Quote

Right after I posted yesterday it was down again, I don't think it's getting better.

Where is everybody?