Thread: 1940 Ford Tudor Build Thread

Threaded View

-

10-10-2017 07:26 AM #11

ďÖÖI had thoughts of purchasing all hot heads brackets and pullies a few months ago. Then I came back down to realityÖÖĒ

I hear you Ryan. Iím using the HH timing cover and lower double pulley and short BB water pump on the Hemi in the 57. I groused about the cost 10 years ago and they sure havenít come down in price.

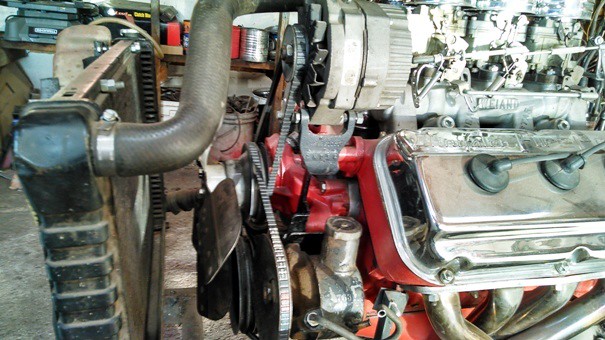

This is what Iím using for pulleys and brackets on my 37.

Iím using the stock early HEMI timing cover and Long BB Chevy water pump.

The upper pulley is a two groove SBC unitÖ..Iím using an original but the aftermarket chrome 2 grove units will also work and may save you some time hunting for an original. If you do eventually do go with the Hot Hemi heads stuff, this pulley will also work with their thin timing cover/lower pulley set up and is a lot cheaper than the HH aluminum one. The lower pulley Iím using is a 3 groove BB Mopar unit but the easier to find 4 groove unit will also work. Due to space limitation Iím using the 3 groove unit because Iím running a flex fan bolted directly to the WP pulley. If I use the 4 groove lower pulley it will require a 1Ē fan spacer. If you have problems finding a 4 groove let me know, I have a spare I can send you.

For an alternator bracket Iím using a modified late 60ís early 70ís Corvette/Chevy truck bracket. Years ago I could buy these new from the dealer for $12.00, the last time I checked they were getting $60.00 for them. If you canít find one off a truck (or have one left over from your smoky old vette ) let me know I think I have a spare.

) let me know I think I have a spare.

Alt Bracket by M Patterson, on Flickr

Alt Bracket by M Patterson, on Flickr

The mods to get it on the Hemi were pretty simple, basically trim the end, and drill a hole so it could bolt to the water crossover tube. As I recall a needed a couple of washers on the back side of one hole to get it to sit square.

37 Dodge Hemi by M Patterson, on Flickr

37 Dodge Hemi by M Patterson, on Flickr

Iím using the same bracket on the 57 so I know it will also work with their timing cover/pulley set up if you go that route later. The biggest concern I had with this set up (and itís the same if you use the HH stuff) is that the belt really doesnít have much of a contact patch on the WP pulley. Itís not a problem if you are running AC as you also have a second belt that also goes around the WP pulley.

For the PS pump and bracket Iím using a Federal pump and brackets from a late 60ís BB Mopar. This may be the hardest part to find. I think this set came off a 440 powered 69 Chrysler but Iím not real sure. If you donít have any luck at the local bone yards you might check on E BayÖ.but keep in mind most mopar guys think their stuff is gold As simple as the bracket is you might be able to fabricate the whole thing out of a couple pieces of flat stocl. If you do find one on the car you will probably want to snag the pump and at least part of the pressure hose with the metal pipe on it.

As simple as the bracket is you might be able to fabricate the whole thing out of a couple pieces of flat stocl. If you do find one on the car you will probably want to snag the pump and at least part of the pressure hose with the metal pipe on it.

FP 1 by M Patterson, on Flickr

FP 1 by M Patterson, on Flickr

FP 2 by M Patterson, on Flickr

FP 2 by M Patterson, on Flickr

I ended up narrowing the bracket so that it would fit the PS boss on the BB Chevy water pump.

MB 1 by M Patterson, on Flickr

MB 1 by M Patterson, on Flickr

I had to fabricate a bracket for the bolt that tensions the PS pump.

T B by M Patterson, on Flickr

T B by M Patterson, on Flickr

That bolted between an alternator bolt and one of the timing cover bolts (the old Hemi used 5/16 timing cover bolts and I replaced the bolt with a stud and nut to hole the timing cover and then slipped the bracket over stud.

TB 2 by M Patterson, on Flickr

TB 2 by M Patterson, on Flickr

When it was all done the front belt goes around the 3rd grove of the crank pulley, the outer grove of the WP pulley and the PS pump pulley. The belt now has a pretty good amount of wrap around the WP pulley.

The alternator is driven from the inner grove of the WP pulley and that belt does NOT go around the crank pulley.

PS B by M Patterson, on Flickr

PS B by M Patterson, on Flickr

Then all you need is a custom pressure hose to connect it to the rack. I had all the pulleys and brackets on hand so I have virtually no money tied up in itÖ..your results may vary

.I've NEVER seen a car come from the factory that couldn't be improved.....

1723Likes

1723Likes LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote

This website will not be worth anything until if becones SECURE!

Not Secure