Hybrid View

-

04-22-2013 09:49 AM #1

Sure Jim, as I've enjoyed your build.

From this picture you will see I've "massaged" the aluminum panel a bit with the bulge to allow clearance for the engine's Ram Horn exhaust manifold.

In the beginning the transmission was a M21 Muncie 4 speed.

But that was when I was running a 355 sbc circle track race engine. Later I built a 383 sbc for torque down low in the rpm band, gave up 100 hp on the high end to have 516 lb/ft @ 2800 on the low end.

That amount of torque would have made the Muncie short lived, so swapped in a Tremec TKO 600 5 speed with 0.64 5th gear.

With the massive torque so low in the rpm band, was able to gear it really tall for cruising and good mpg. Broke 30 mpg on a couple of trips. This picture is up hill in 5th and about 1025 rpm.

As much as I enjoyed the grunt of the 383 over the 355, I missed the high rpm zing of the 355, so the next engine gave that back to me. You probably won't have to go to the extremes I've had to in keeping the engine cool with a radiator that fits inside our track noses, but mine is a 3 core and 2 core married to the same tanks and then a custom fabbed fan shroud to pull as much air as possible through it.

Last edited by deckofficer; 04-22-2013 at 10:35 AM.

Bob

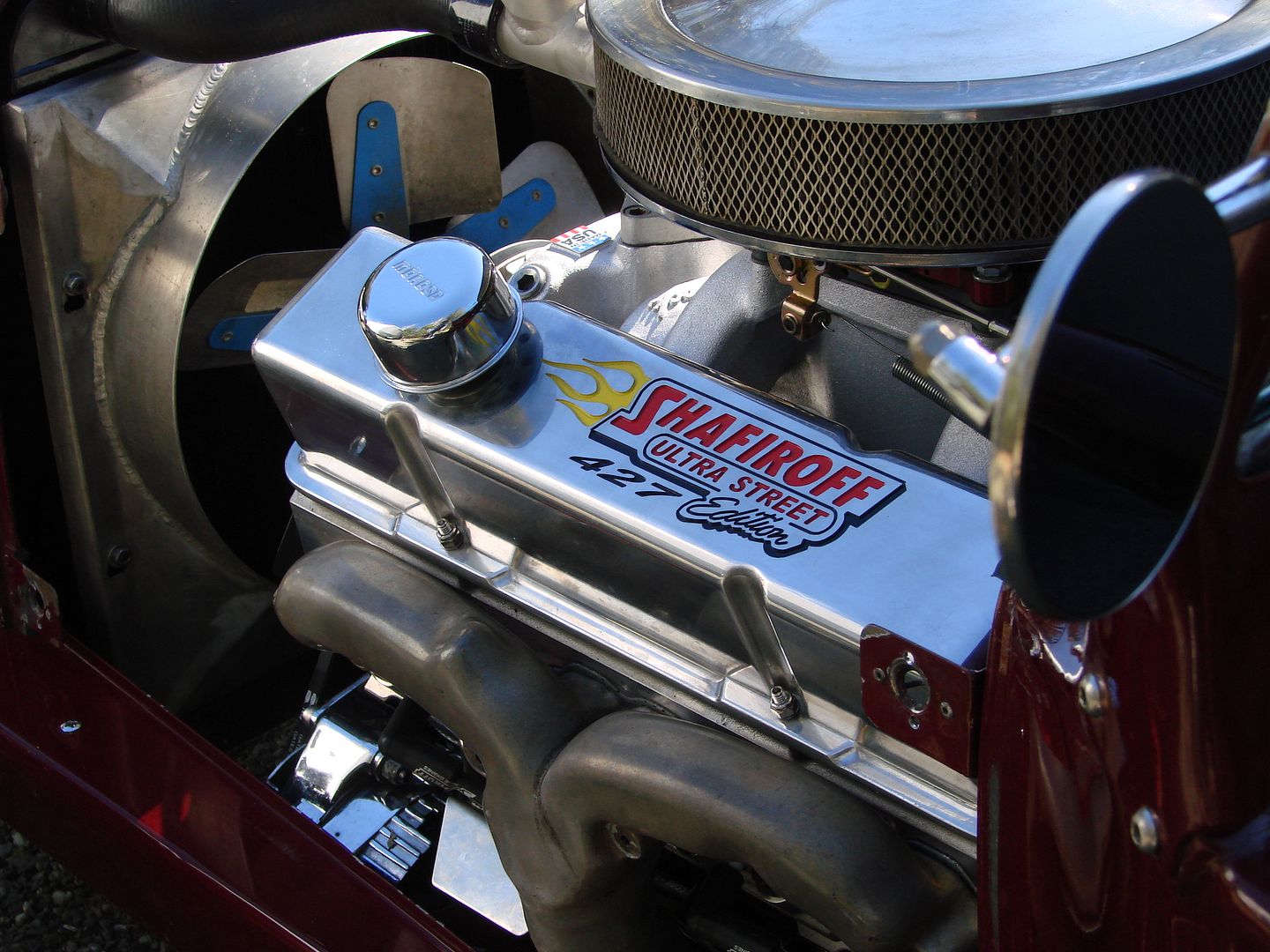

427 sbc 526 HP 556 lb/ft

Tremec TKO 600 5 speed

1790 lbs.

-

04-24-2013 06:25 AM #2

What can I say? NICE, NICE, NICE!! I love track T's and what a nice specimen you have built! Those old Muncie 4-speeds used to hold up fairly well behind some pretty beefy big-blocks in cars a lot heavier than your T, but the 5-speed is a nice upgrade anyway.

Those old Muncie 4-speeds used to hold up fairly well behind some pretty beefy big-blocks in cars a lot heavier than your T, but the 5-speed is a nice upgrade anyway.

If I am unhappy with my 4-banger when I get this thing on the road, it will get replaced with a small-block. Lack of extra $$$ now that I'm retired will keep it mild-mannered, though. That 427 small-block must be a handful when you stomp the "loud pedal".

I like it; I wish I could see it in person...

I like it; I wish I could see it in person...

Jim

Racing! - Because football, basketball, baseball, and golf require only ONE BALL!

-

04-24-2013 02:29 PM #3

The M22 Muncie or "Rock Crusher" would of had no longevity problems with 516 lb/ft of the old 383, but I had the M21 that was used with the small blocks. Great trans and I still have it.

As to the loud pedal, you will soon find out that when the car weighs less than 1800 lbs (probably less than 1600 lbs in your case), it will hook and book. I can't roll it all on in 1st, but if I short shift at 30 mph into 2nd, my rpm is low enough that I can roll it all on and if road surface is good, will hold traction all the way to 60 mph before it starts losing traction. 3rd gear never a problem, so hang on.Bob

427 sbc 526 HP 556 lb/ft

Tremec TKO 600 5 speed

1790 lbs.

-

04-24-2013 08:10 AM #4

Good news; I finally had the roadster running long enough to get the thermostat open and get the coolant circulating. The engine seems to run good, no smoke, and no unwanted noises. The bad news is it won't idle.

The engine seems to run good, no smoke, and no unwanted noises. The bad news is it won't idle. I have checked for vacuum leaks and played with the timing to no avail. Apparently the old junkyard carburetor has an internal problem and will need a rebuild (or replacement).

I have checked for vacuum leaks and played with the timing to no avail. Apparently the old junkyard carburetor has an internal problem and will need a rebuild (or replacement).

With the engine in running order, I have reached the point where I need to keep tabs on what's happening internally, so I need to get the gauges mounted and working. That means I need to fabricate the dash panel! I could build another wood masterpiece like I did for my coupe, but this track-T is supposed to replicate an old race car and back in the days of the "Roaring Roadsters" the interiors were very spartan. Often, the cars only had an oil pressure gauge and some had no gauges at all! As the roadsters evolved more and more toward sprint cars and the engines became more radical and expensive, gauges became necessary, so dash panels of some sort became common. Certainly, a dash panel would be utilitarian and therefore made of steel or aluminum. Since the beginning of this build I have intended to make the dash from aluminum and engine turn it to match the firewall.

I began by making a pattern from my good old standby template material, poster board. This Dave Koorey body has a dash in it that is pretty narrow (measured vertically), so there is limited space for fitting the gauges. The problem here is compounded by the under-dash support structure that I built to accomodate the cowl steering; everything has to be mounted to the right of the steering column. Therefore, the gauges have to be clustered near the center of the dash panel. After a lot of cut & try fitting, taping my mistakes back together, and cutting again, I finally arrived at a shape I like. The first pic is the finished pattern taped in place. Next is the pattern being transferred to the back of the .063" aluminum (You can see all the taped mistakes on the back of the pattern here). the last pic is the aluminum panel with the gauges fit into it. These are Dolphin gauges; black face with curved glass similar to old-time Stewart Warners.

Jim

Racing! - Because football, basketball, baseball, and golf require only ONE BALL!

-

04-24-2013 08:54 AM #5

Very cool, and the cut & tape is why poster board is such a great tool!! Looking forward to how you accomplish the engine turning, to keep everything aligned & symmetrical. Always been intrigued by that design.Roger

Enjoy the little things in life, and you may look back one day and realize that they were really the BIG things.

-

04-24-2013 09:06 AM #6

Looks great Jim, getting anxious for the road test on this one I'd bet??????Yesterday is history, tomorrow is a mystery, Live for Today!

Carroll Shelby

Learning must be difficult for those who already know it all!!!!

-

04-24-2013 10:52 AM #7

Jim nice simple dash. I like the gauges in the middle. my current convertable has the speedo under where your left hand sits on the steering wheel, making it hard to see what speed your doing. My old jeep cj7 had the center mount gauges which I always liked, long of the short should work well there."  "No matter where you go, there you are!" Steve.

"No matter where you go, there you are!" Steve.

-

04-25-2013 10:11 AM #8

Dave - Yes! I'm anxious for that first time around the block. Soon, very soon... I hope.

Steve - My coupe has the gauges in the center, too, and they're easy to read that way. I plan to mount the tachometer on the steering column like '50s - '60s era; that's why there isn't one in the dash.

Bob - I don't know what this thing weighs yet, but it's pretty light. My son and one of his buddies grabbed the front bumper one day and lifted the car up so the buddy's girlfriend could get the jackstands out from under it! Even with the little 4-banger it should be fun to drive...

Even with the little 4-banger it should be fun to drive...

Jim

Racing! - Because football, basketball, baseball, and golf require only ONE BALL!

-

04-25-2013 07:50 PM #9

I left off last time with the aluminum cut to shape and hole-sawed for the gauges. Next step was to re-fit the panel in the car, mark the gauge holes, and cut out clearance in the fiberglass for the gauges. Also, I drilled the mounting holes that will hold the whole thing in place. The good news here was the two end holes went right into the steel support underneath, so I was able to tap the holes and permanently install studs. The two holes that are close to the gauges get bolts with big fender washers to spread the pressure on the back side.

Jim

Racing! - Because football, basketball, baseball, and golf require only ONE BALL!

-

04-25-2013 07:56 PM #10

With all the holes drilled, it's time to finish the panel. I used my cordless drill and a 1 inch diameter wire brush (same as I used on the firewall). The pattern is achieved by using a straight edge fixture (I used a 1 x 4 board) clamped in place to guide the rows of brushed circles in a straight line. Controlling the drill is a challenge at first, so I recommend practicing on a scrap piece until you “get the hang of it”. Start at one end of the top or bottom edge and work all the way across, overlapping each circle by one half the diameter. I am left-handed, so I find it easier to control the drill / brush if I start at the top and work from right to left. When I finish a row I move the guide one half the diameter of the brush and do the next row. There is another detailed explanation of the process back on page 27 of this thread. Once done with the "engine turning" process, I cleaned the panel with wax & grease remover, loaded my spray gun, and gave the panel three wet coats of clear acrylic urethane. The last pic below shows the finished panel with chrome acorn nuts holding the panel in place and the gauges installed.

Jim

Racing! - Because football, basketball, baseball, and golf require only ONE BALL!

-

04-25-2013 09:40 PM #11

-

04-26-2013 06:29 AM #12

Thanks for the explanation of the engine turning process, Jim. I had vague memories of reading something years ago about valve lapping compound and a dowel but your rotary brush worked pretty slick!Roger

Enjoy the little things in life, and you may look back one day and realize that they were really the BIG things.

-

04-26-2013 07:05 AM #13

And IMHO, if you have access to a drill press the job can be accomplished with more accuracy and consistency.Ken Thomas

NoT FaDe AwaY and the music didn't die

The simplest road is usually the last one sought

Wild Willie & AA/FA's The greatest show in drag racing

-

04-28-2013 03:01 PM #14

Bob - Thanks. Great minds think alike. I like having a glove compartment (I put one in my coupe) and I may steal your idea...

Roger - I have also heard of the dowel rod & valve lapping compound and I have seen some absolutely beautiful examples of the finished product, but I have never tried it. It must take forever to finish a panel that way. I came up with this wire brush and straight-edge process back in 1975 when I was building Quarter Midgets for my nephews and I used it again on the firewall of my C-Cab hotrod in '76. Using this method, once I get a rythm going, I achieve brushed dots or circles at the rate of about one per second. I soon found out that greasy fingerprints are almost impossible to remove from the raw aluminum surface, hence the clearcoat that I use now.

NTFDAY - Yes, I agree that a drill press could / would produce more consistency, but it would require building some kind of fixture to hold the workpiece and move it accurately in a straight line. Also, the depth of the throat on a drill press would limit the size of the workpiece which would have been a problem on my firewall (see page 27).

Jim

Racing! - Because football, basketball, baseball, and golf require only ONE BALL!

-

04-28-2013 03:10 PM #15

Know what you mean. it's how I did it in 61 when I was in high schoolKen Thomas

NoT FaDe AwaY and the music didn't die

The simplest road is usually the last one sought

Wild Willie & AA/FA's The greatest show in drag racing

73Likes

73Likes

LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks Reply With Quote

Reply With Quote

time for a new forum to visit. when they sold sr.com it went down hill fast. no more forum just a cheap site selling junkie cars. the canadians killed hr.com. mods are real pricks. as with any site...

Where is everybody?