Thread: 32 ford truck project

Hybrid View

-

11-01-2013 04:35 PM #1

Got the brake lines started. Using 3AN stainless fittings and 3/16 stainless lines... Not real happy how these came out so they may change.

Intake came in and I couldn't resist tossing it on the engine

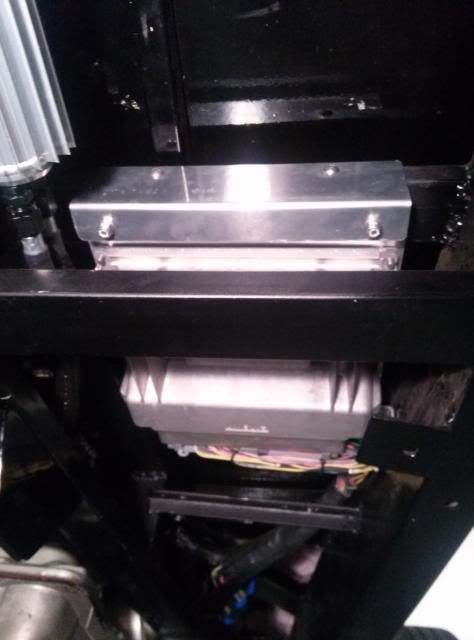

Well Finally got the PCM mounted. I used MSD isolators to avoid any possibility of shorting it out.

Shortly after cleaning the garage up I got a call from the boss and he let me know my "spot" in the shop had opened up...

So I immediately loaded it up and had it at the shop at 8am the next morning.

In it's spot

Started on the radiator first... FML

Next I pulled out the outlet from the waterpump and welded up a 90 to kick it straight up to the inlet of the radiator.

After much thought I cut up the thermostat housing and made some parts on the lathe to make my own housing. This will be a huge help in getting the outlet of the radiator hooked up.

My rod-ends made it and screwed them on to give you the idea of how we are using the radiator support bars. Beats the hell out of using nuts to pinch a bracket on top of the radiator. The rod ends in the first pic are aluminum. The lower pic is stainless. I think I'm going to run the stainless ones after a bit of work on the buffing wheel.

Also got my big nasty Spal 2082 Fan... 16" Paddle blade is wicked and should pull the truck along with the CFM it pulls... HYBRID? LMAO

-

11-22-2013 10:28 AM #2

Small update. We have been working a little bit on the radiator and about got it finished up.

Tanks, Filler neck, and hose inlet and outlets welded up.

Spun up some mounting bungs for the rod ends... The bolts have been replaced with the proper size stainless shoulder bolts now.

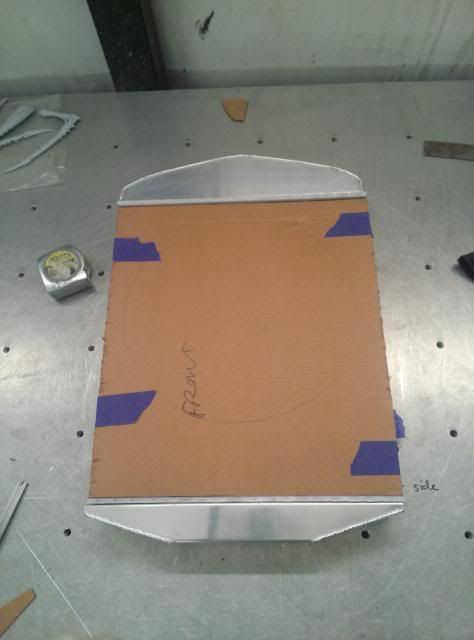

Test fitting

Getting the side trim made, pressure testing, and test fitting again

Made mounting tabs and got the condensor mounted and got the fan mounts made and welded.

got the frame mounts done and the thermostat welded up. The upper and lower hoses are fitted. Next will be mounting the grille and making an overflow tank then the cooling system will be done.

-

10-13-2013 10:10 AM #3

Well thought out, a real 'Pocket Rocket' ! Thank's for the great

'porn' pics. Great detail on everything.

Rich

-

10-14-2013 12:44 AM #4

very impressive build!!!

just read the whole story right thru.

luv it ,thank you for the details and photos.

mark

-

10-14-2013 08:15 AM #5

Awesome build, nice attention to detail, especially the one-off brackets!Robert

-

10-14-2013 08:59 AM #6

I am liking this build a lot. Nice work. That is going to be one sweet ride when it hits the streets. Thanks for all the visuals--keep them coming!!

Lynn

'32 3W

There's no 12 step program for stupid!

http://photo.net/photos/Lynn%20Johanson

-

11-22-2013 10:49 AM #7

Clever way to mount the radiator supports! Nice work!!

Lynn

'32 3W

There's no 12 step program for stupid!

http://photo.net/photos/Lynn%20Johanson

-

11-22-2013 01:46 PM #8

-

11-22-2013 11:11 AM #9

That's beautiful work! And thanks for sharing the pics.

Quick question, are you going to cover the rest of the rear of the radiator? The area above and below the fan, to increase the air drawn through by the fan for times like when in traffic?

-

11-22-2013 01:52 PM #10

In short no I will not.

After much thought and talk a shroud would have eaten up another .250"-.500" of valuable space. If I had gone the shroud route I would have had to stick the grille out further and it would have started looking like pinocchio.

That being said. My background with automobiles started opposite of most. I started building late model stuff mainly GM LS based cars/trucks. I have slowly been working backwards to working on older stuff. Which I thoroughly enjoy. I have built vettes and camaros that made 800-1000 HP and did it on the factory radiator. If you look at GM factory radiators they are a joke in terms of overall core size and the air path for the radiator is really restricted.

So given the past I feel 100% confident that it will cool just fine especially with that nasty 16" puller that will be moving air.

Thanks for the question.

-

11-22-2013 04:03 PM #11

You may be right.. I didn't cover my core either! And it runs right on the thermostat! Never a degree higher or lower.

And like you I never "played" with the older technology until I become bored with a 67 Mustang after nearly 20 years.

Thanks for the reply.

-

11-27-2013 11:23 AM #12

Not much if an update as the shop is shut down for the week and I'm at home bored out of my mind.

I did get my master cylinder top that we had machined. After a couple hours sanding and polishing it came out decent.

-

11-27-2013 01:01 PM #13

Dang, that looks nice! I can send you some parts... since you're bored I mean!!

-

11-27-2013 01:14 PM #14

Well boredom continues.

I bought these a while back and they came anodized clear. I'm not a fan of clear anodizing on raw machined aluminum. So I rummaged through the house and found a bottle of Draino MAX. Ah HA Sodium Hydroxide! after a 20 minute soak and a quick scrub with soap, water, and 0000 Steel wool I hit it with the buffing wheel... Came out good. Too bad the rest of my parts to build the coolant overflow tank are at the shop

-

11-27-2013 03:27 PM #15

This is a Great!!!

Thank You for sharing, & good tip on cleaning the anodized!!

The valve cover pieces are definitely awsome!!

The project is just plain bitchin'!!!! :-)

142Likes

142Likes

LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks Reply With Quote

Reply With Quote

time for a new forum to visit. when they sold sr.com it went down hill fast. no more forum just a cheap site selling junkie cars. the canadians killed hr.com. mods are real pricks. as with any site...

Where is everybody?