Hybrid View

-

04-07-2020 11:23 AM #1

More progress on the hood, here is the other end of the hood brace.

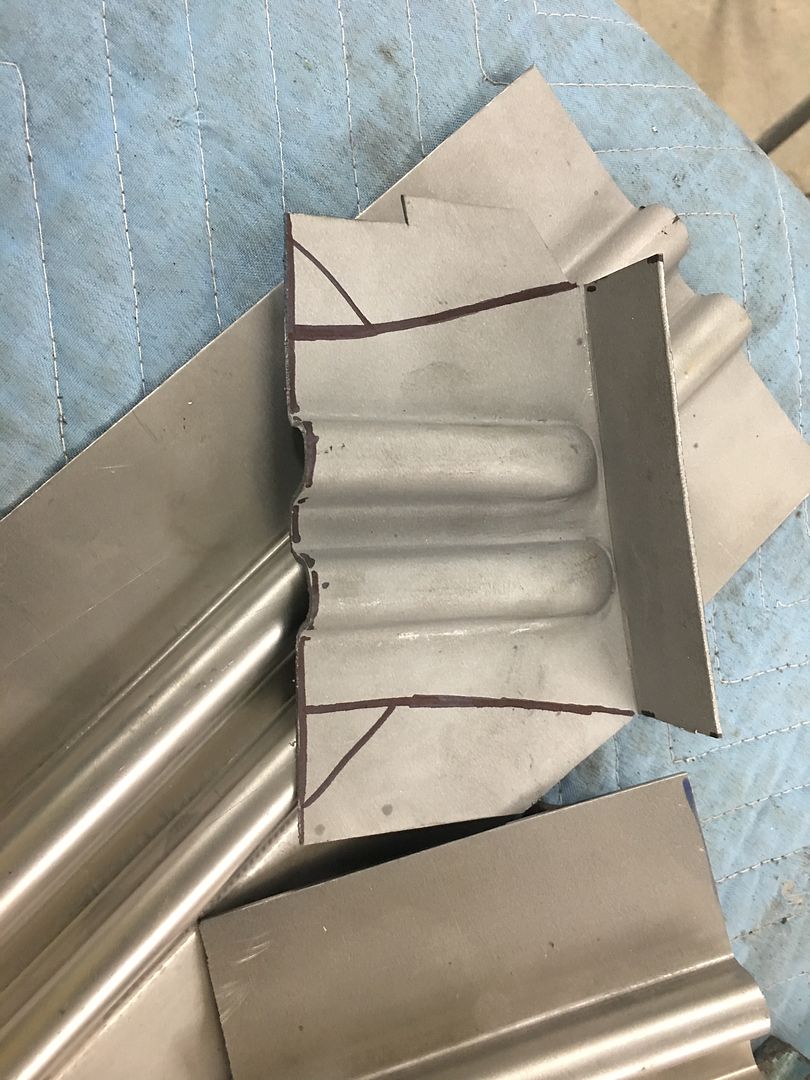

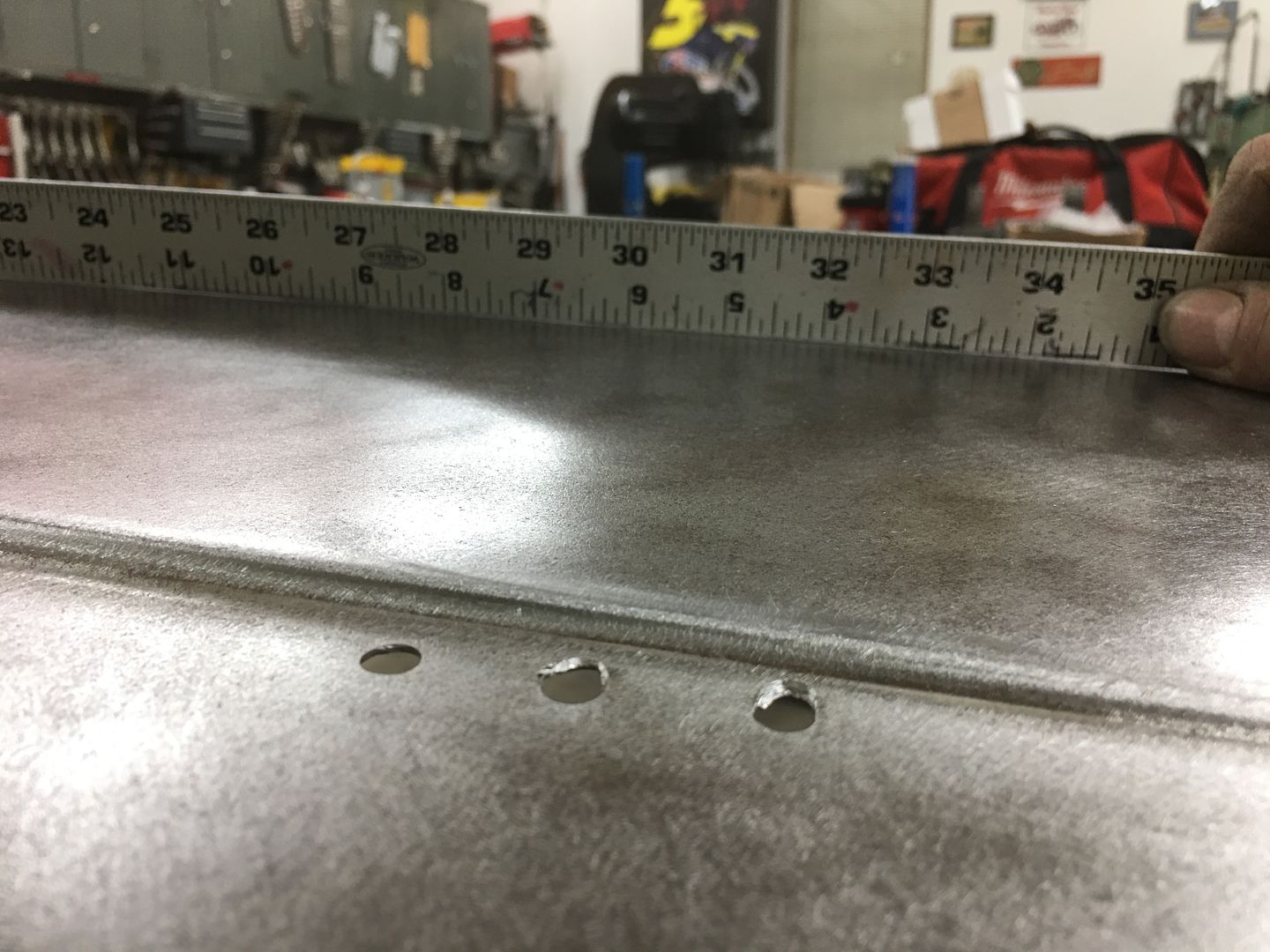

Looking at the back side, you can see where a few holes were welded closed the last time it was painted, and the severe pitting and new holes that we have. A testament to the fact that what shows is always the tip of the iceberg. Although better than the passenger side, this is definitely one of those "while we are here" things. Do it right, do it once. (grinder marks were mine)

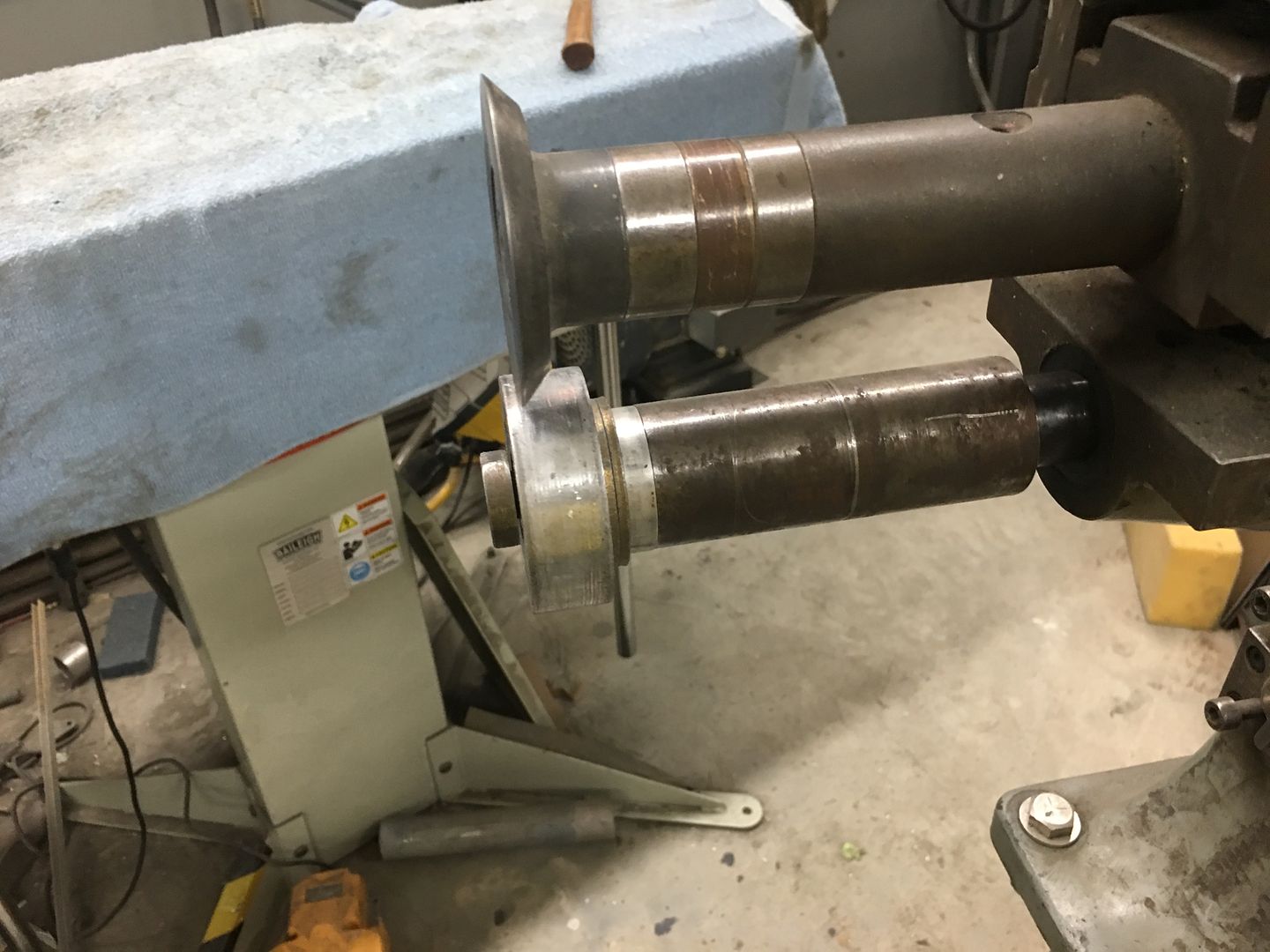

With our new replacement all one piece, the next step is to bend the flange that spot welds to the hood skin. A tipping wheel in the Fasti-werks bead roller makes quick work of it. The bend line was transposed from the original and an initial pass under the tipping die marks the crease line a bit better, Then successive passes are made, lifting slightly with each pass. This is done until the beads interfere with the tipping die.

Then the partial bent flange is clamped in the magnetic brake for the remainder of the fold. This brake allows us to use a die on either side of the bead details, where a full die may inadvertently push in on the beads.

End gets cut to length and marked for initial trimming

Looks like we may have enough bead stock left for another couple of ends.

That's where we left off yesterday, we'll see about welding the new end on today..

.Robert

-

04-08-2020 07:25 PM #2

Our last end for the hood brace. Off with the old.....

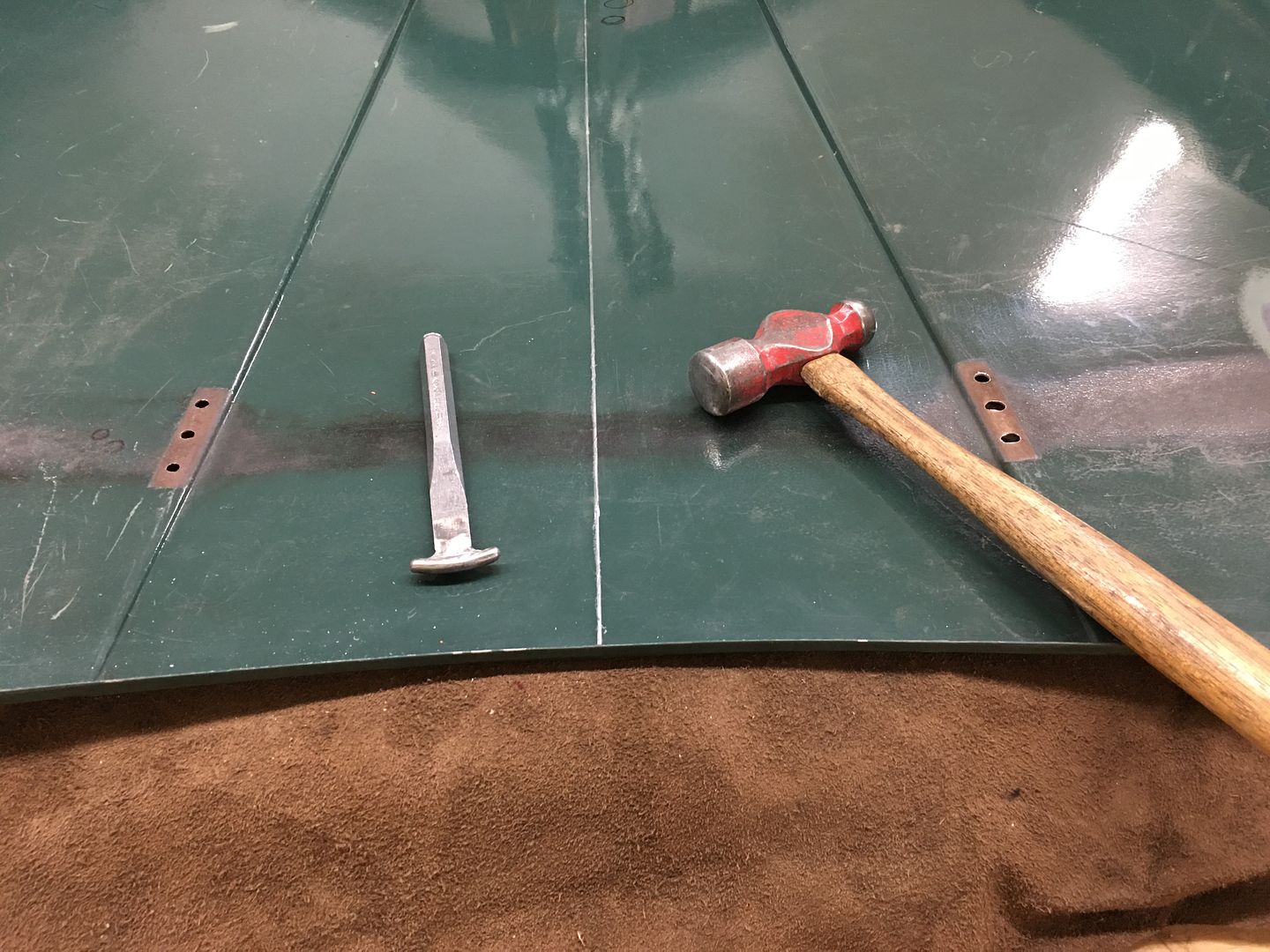

Then it gets trimmed to our scribe line and the end media blasted in prep for welding. Our new end is test fit and trimmed until we get the right distance to our reference marks. The "batwings" give us a heat sink at the edge for less chance of burning back the edge at the weld.

The center rib is aligned both on the sides and the face, and tacked in position using the TIG.

The pieces are aligned as we work outward, tacking as we go. A "corking tool" is used as a dolly where any bumping may be needed for alignment.

Tacked...

Welded....

Welds cleaned up and end angles compared..

Now we can get back to straightening sheet metal..Robert

-

04-21-2020 09:14 PM #3

We have a few more spots to fix from cracking and fatigue, namely the holes on the underside for the rubber hood bumpers. We've already repaired three, and from the looks of it, need to take care of the remaining three..

18 Gauge x 1/4" plugs were TIG welded in to fill the existing holes, and a copper backer gives us a bit of a heat sink so the cracks/fatigued areas don't blow a big hole on us..

Welds were dressed on both sides of the sheet metal, and new holes drilled slightly in farther from the edge to help slow down the reappearance of cracks.

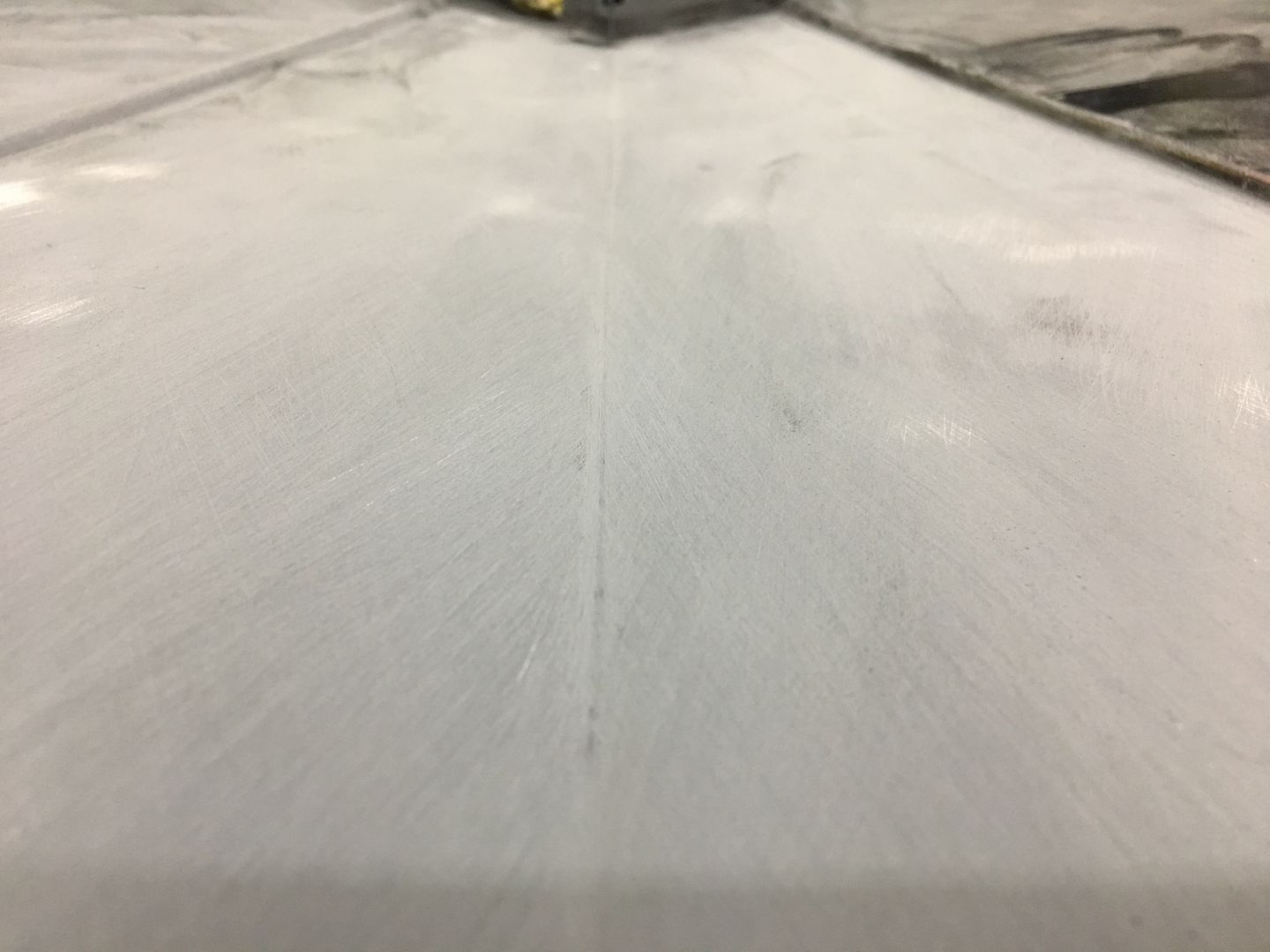

Next, I'm sure everyone has seen how these hoods can oil can, show low spots, and try to flop around while driving down the road. Part of that is abuse over the years, fatigue, etc. Any low spots invariably result in a loss of support of the hood and will show oil cans or loose areas.

A good tool to check the crown of the hood is a long straight edge in the form of a 36" rule. If you don't have one, most hardware stores sell aluminum flat bar for a few dollars that will make a good profile template. For this style hood, lows are bad, straight is better, and a slight crown in the center crease along the entire length of the "flat" area of the hood is optimal.. This gives the support to help eliminate those oil cans and floppy hoods.

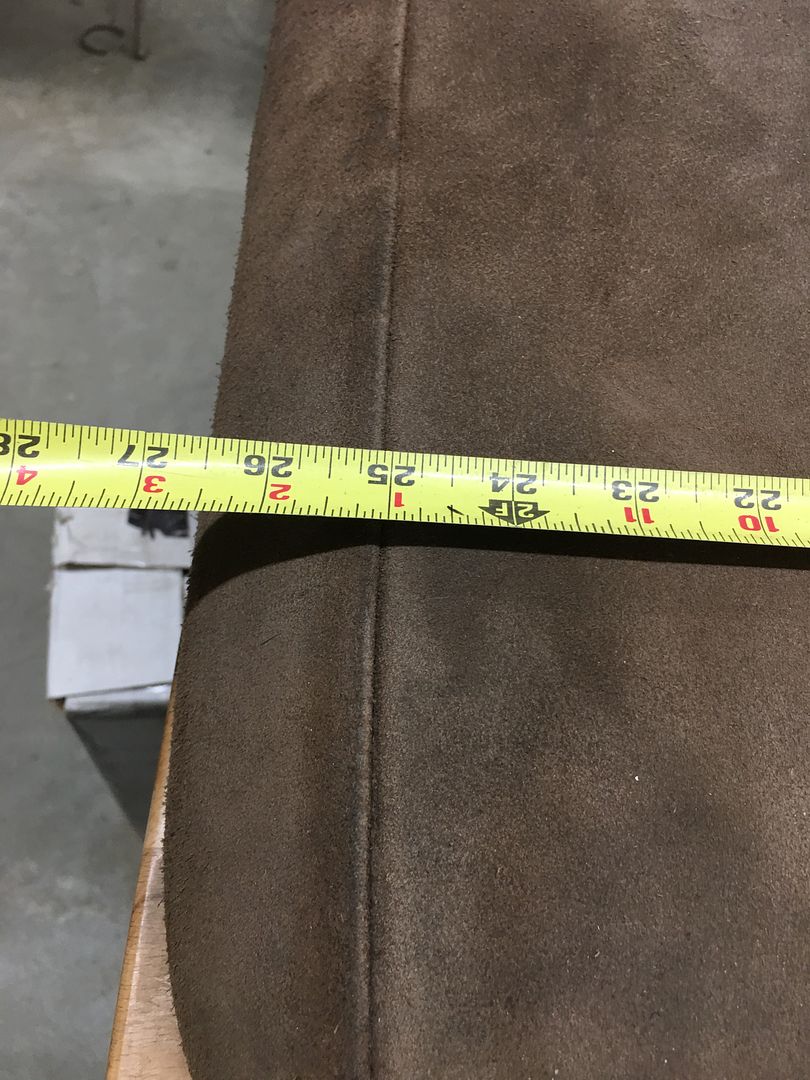

When we started there was an obvious area about 12" forward of the rear edge, dead center, that appears low, and was easily pushed downward. In order to better define the center crease and provide the support needed, we will use a sand bag (a rather large one) and lightly hammer from the bottom side into said bag with a purpose built "punch".

In order to keep the back portion of the hood down against the bag for support, we used our latest "metalshaping" tool to hold the front of the hood up, an engine hoist..

A reference mark is used on the inside, measured and centered...

The crease was checked for low spots prior, and the bottom marked. The "punch" is dragged along the centerline and tapped as you go. Flip the hood over, check crown, remark as needed, repeat. We got to a good straight/slight crown and the oil can disappeared. Pushing along the entire center crease was a nice tight support now..

So if you are having issue with your hood, I would suggest first checking your center crease.Robert

-

04-22-2020 02:06 PM #4

- Join Date

- Apr 2011

- Location

- Prairie City

- Car Year, Make, Model: 40 Ford Deluxe, 68 Corvette, 72&76 K30

- Posts

- 7,301

- Blog Entries

- 1

More awesome work and great tips too!Ryan

1940 Ford Deluxe Tudor 354 Hemi 46RH Electric Blue w/multi-color flames, Ford 9" Residing in multiple pieces

1968 Corvette Coupe 5.9 Cummins Drag Car 11.43@130mph No stall leaving the line with 1250 rpm's and poor 2.2 60'

1972 Chevy K30 Longhorn P-pumped 24v Compound Turbos 47RH Just another money pit

1971 Camaro RS 5.3 BTR Stage 3 cam, SuperT10

Tire Sizes

-

04-22-2020 02:31 PM #5

If only I had a gigantic sand bag like that.

-

08-31-2020 09:47 AM #6

Thanks Guys!!

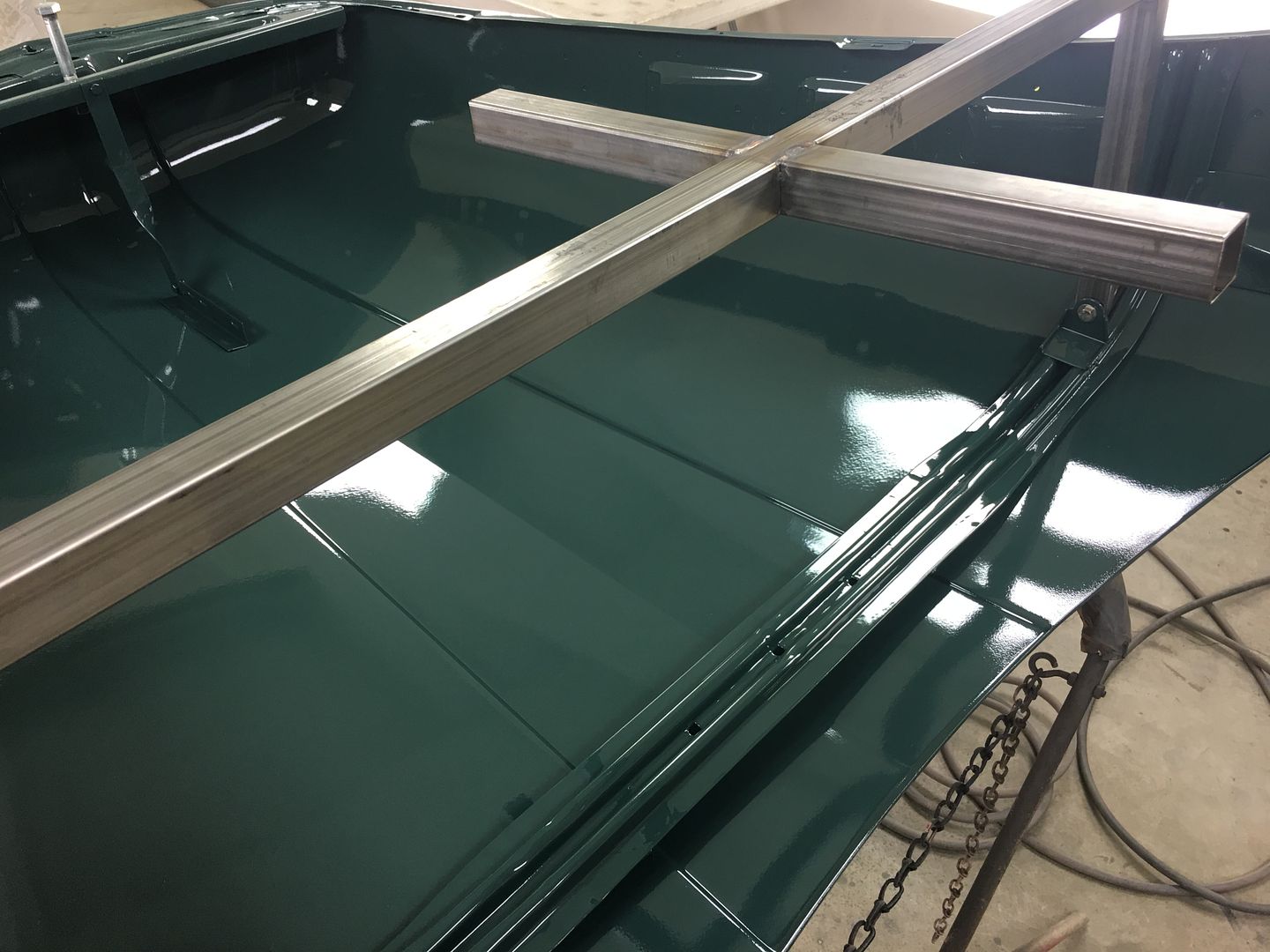

The 51 F7 hood is closer to reuniting with the brace with the newly repaired ends.. Epoxy primer will be under the brace this time around to help prevent the new side patches from rusting again..

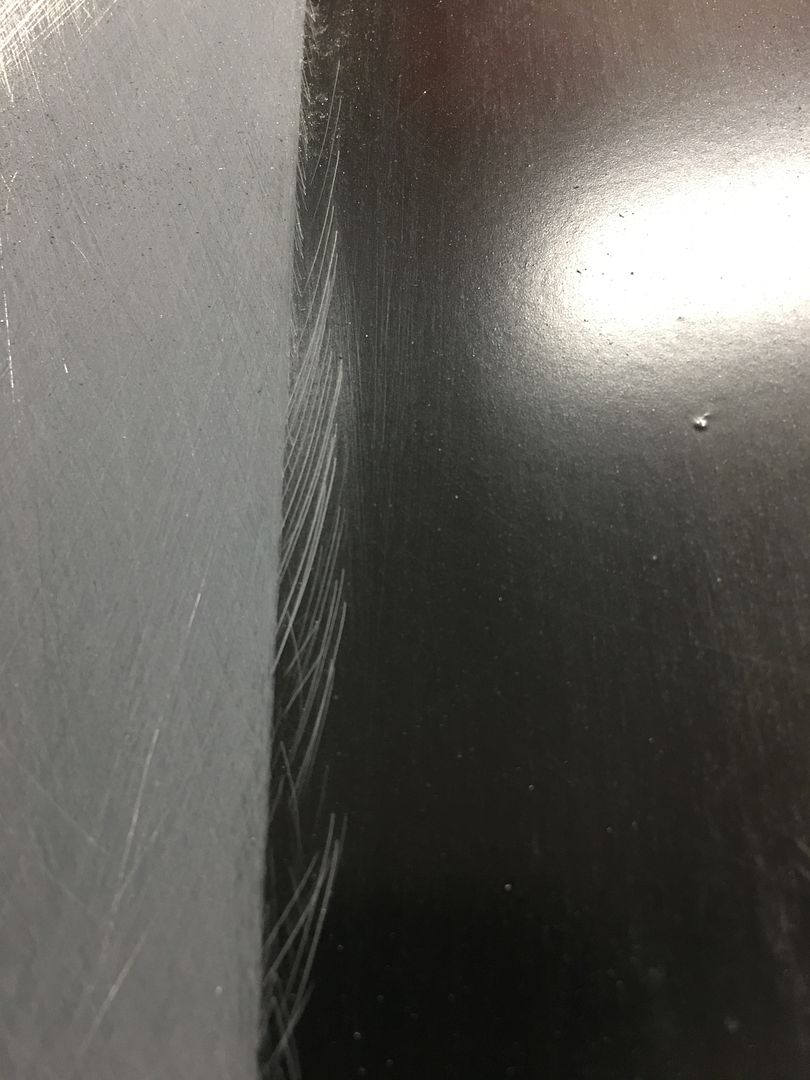

Some blocking tips on the F7 hood. We have a nice crease on the inside of the hood from front to back. These scratches show that we would be taking material off the adjacent side if no other steps were taken to stop our sanding block at the center of the crease...

By adding a strip of tape along the center, it gives us a positive stop for the sanding block..

Then switching for the other side....

Which leaves us a nice crease in the middle, and panels nice and flat to either side...

Final blocking on the inside using tape to keep the center line sharp, then brace welded in place and some epoxy touch ups done..

With the touch ups blocked, we're ready for some Epoxy/sealer, some PPG ESSS base, and my first time spraying SPI Universal... WooHoo! love this clear!!

These Ford truck hoods can be a pain to get good paint coverage inside the nose.. So a couple pieces of TIG wire from our rack to the hood brackets hold it up in the air so we can get into the nose with the spray gun..

Robert

-

09-01-2020 10:24 PM #7

Thought I'd do a progression of pictures to show the carnage we started with on the hood brace to where it was painted this past weekend....

https://www.youtube.com/watch?v=NDZyTTuUGVE

Note the wings left adjacent to the weld to act as heat sinks and prevent the edge from burning back...

No Body filler, just epoxy primer, basecoat, and clearcoat. Looks almost factory!!

Robert

-

09-17-2020 05:43 AM #8

So every time we place the hood on my folding stand, the hood skin deflects upward at those pressure points (corners). Which means that won't work for blocking out the hood. So lets' use the same supports that the hood uses and make a blocking "stand".

Large 5/8" bolt through the hood latch hole for supporting the nose...

And going through our scrap inventory, here's some tubing we used for the back end, bolted into the hinge support. The extra "feet" help to stabilize it so the sanding effort won't try and flop it over...

With that done, all our open holes are taped over and the entire bottom side masked off to protect the inside finish..

A bit of Evercoat 416 to address some lows, and 3 coats of SPI epoxy for the next round of blocking on the outside.

Blocking...

Some booth clean up and fresh masking on the table, hood pre-cleaned and tacked.....

Sealed with SPI Epoxy thinned about 10%

Fleet paint that was used originally on the truck, supplied by owner. Orange peel in a can..

2 coats of color, 2 coats of SPI Universal Clear...

Robert

-

09-17-2020 02:23 PM #9

"Orange Peel in a can".... rotflomao!

-

09-17-2020 05:24 PM #10

johnboy

Mountain man. (Retired.)

Some mistakes are too much fun to be made only once.

I don't know everything about anything, and I don't know anything about lots of things.

'47 Ford sedan. 350 -- 350, Jaguar irs + ifs.

'49 Morris Minor. Datsun 1500cc, 5sp manual, Marina front axle, Nissan rear axle.

'51 Ford school bus. Chev 400 ci Vortec 5 sp manual + Gearvendors 2sp, 2000 Chev lwb dually chassis and axles.

'64 A.C. Cobra replica. Ford 429, C6 auto, Torana ifs, Jaguar irs.

-

09-21-2020 04:50 AM #11

This past Friday night we cut and buffed the F7 hood to get rid of some dust nibs, and Saturday morning Jared and I started to reassemble the hood. The horn wiring had some dry and cracking insulation sleeving, so it was replaced as well.

John stopped by mid morning and we got all the parts put back together and adjusted. Looks much better with the hood back on, John has been driving without one for a couple months.

All ready for the Tri-state Antique Truck Show this week in Clear Brook VA..Robert

-

09-21-2020 07:59 AM #12

That is a fine looking truck! Ya' did good, Robert, but then we all know you always do!Roger

Enjoy the little things in life, and you may look back one day and realize that they were really the BIG things.

-

09-21-2020 08:50 AM #13

That truck is way to beautiful to use as a truck. Great work!

-

09-23-2020 09:45 PM #14

-

09-21-2020 10:02 AM #15

times 3... great work as always. congrats to the crew!

260Likes

260Likes

LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote

.JPG)

.JPG)

.JPG)

I bought the 76 in August , but haven't been able to work on it. When I get a chance I'll post some pictures.

Corvette Resurrection?