Thread: Aoto Body explained..

Threaded View

-

02-06-2012 06:24 AM #11

If you have access to both sides you will have more options for any area needing repair. Here is a School bus luggage door I repaired after someone ran down the side of it. This was the "good" door, the one in front was replaced with a new one.. But as new ones in primer go for just under 1K, we tried to save some money with a repair.....

This repair is done with a "donut dolly" and a crowned face body hammer. The theory here starts with the understanding of how the dent is formed, a direct force against the panel causes a stretch and deformity in the direction of that force. Then indirect forces (I call them springback) will tend to push back on the outer perimeter of the dent, noticeable as an outward bulge slightly higher than the surface of the metal.

Here's our dented sample today, an aluminum door skin with a nice crease that travels just about the full length of the door.

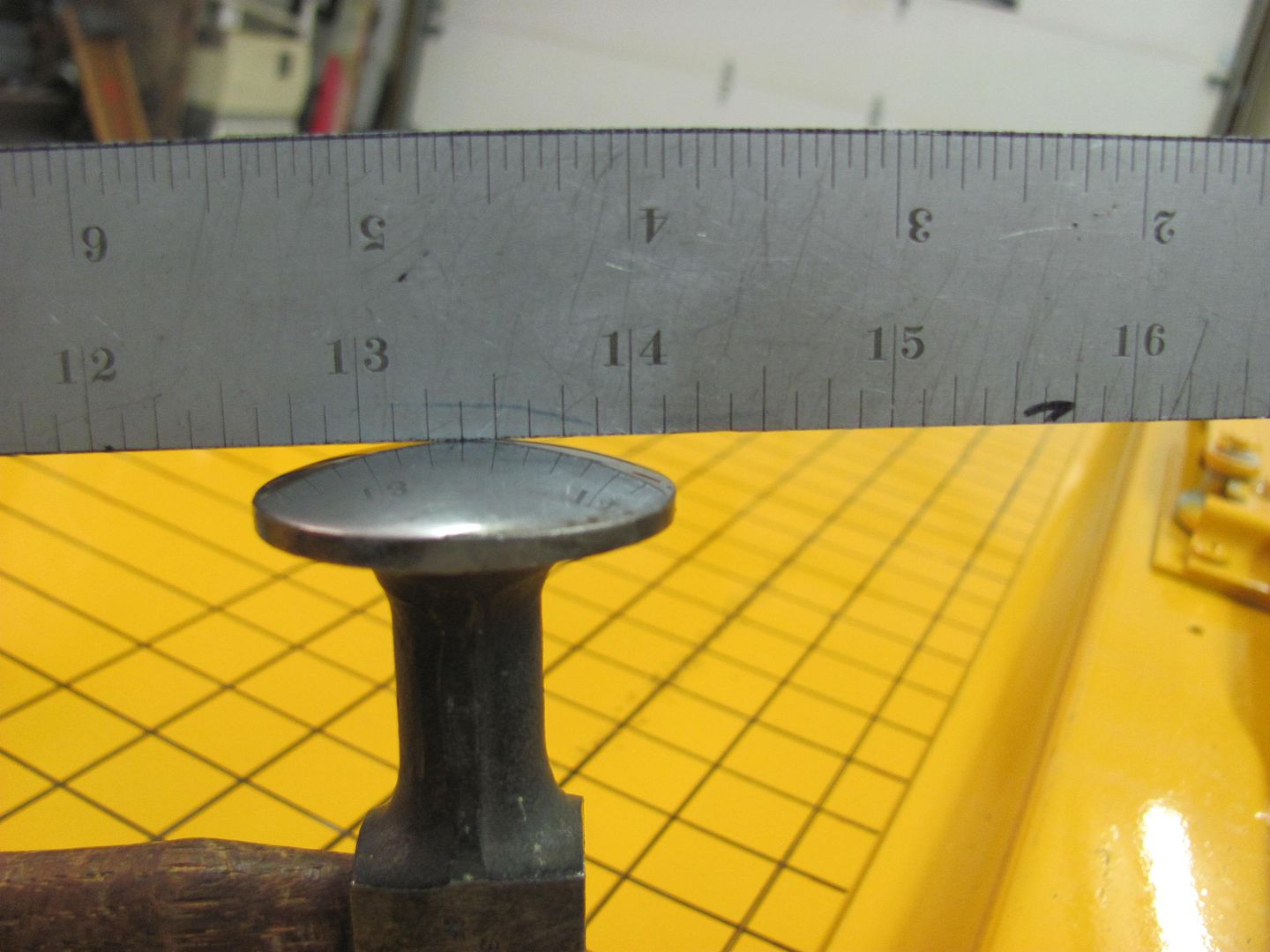

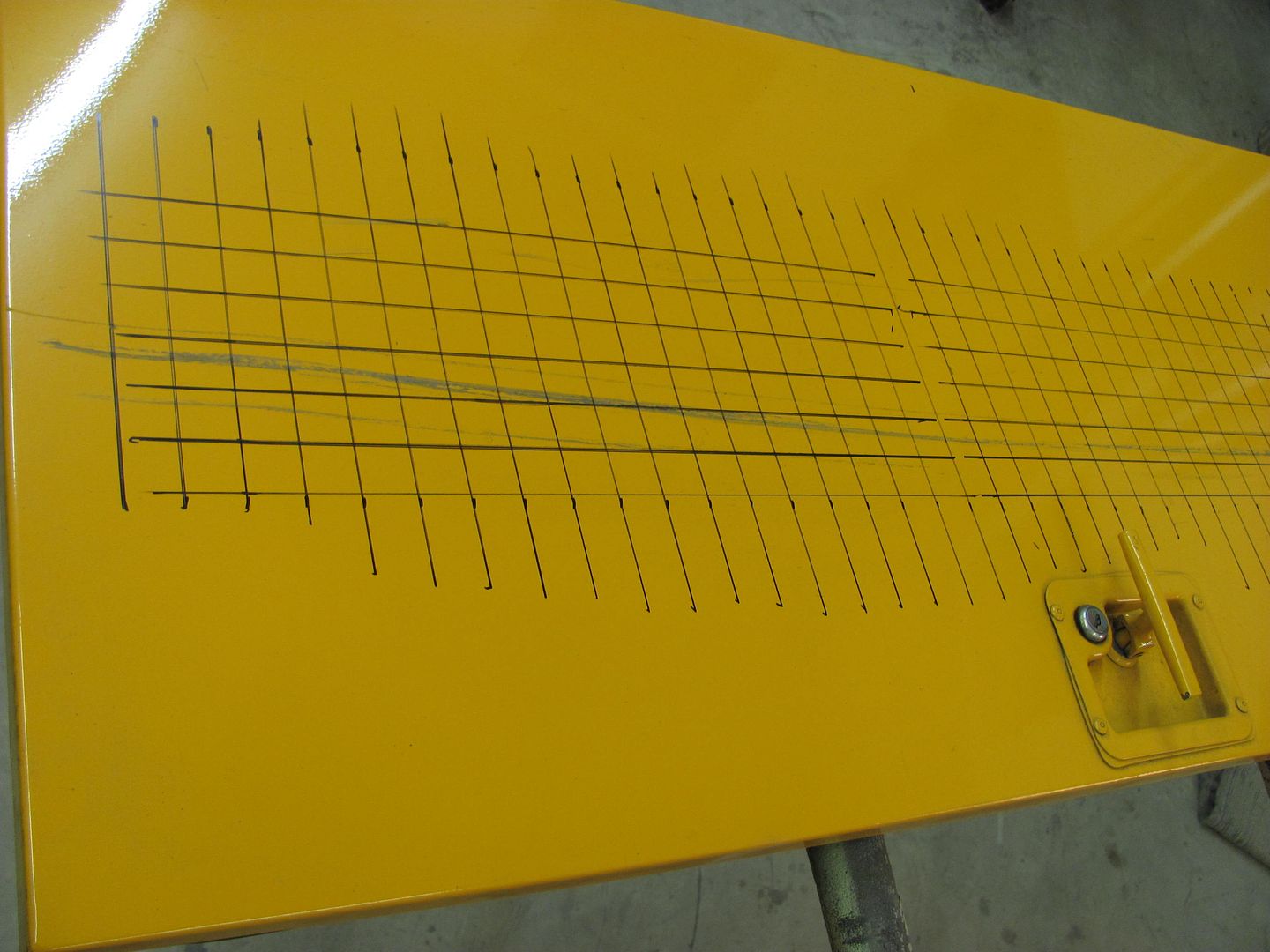

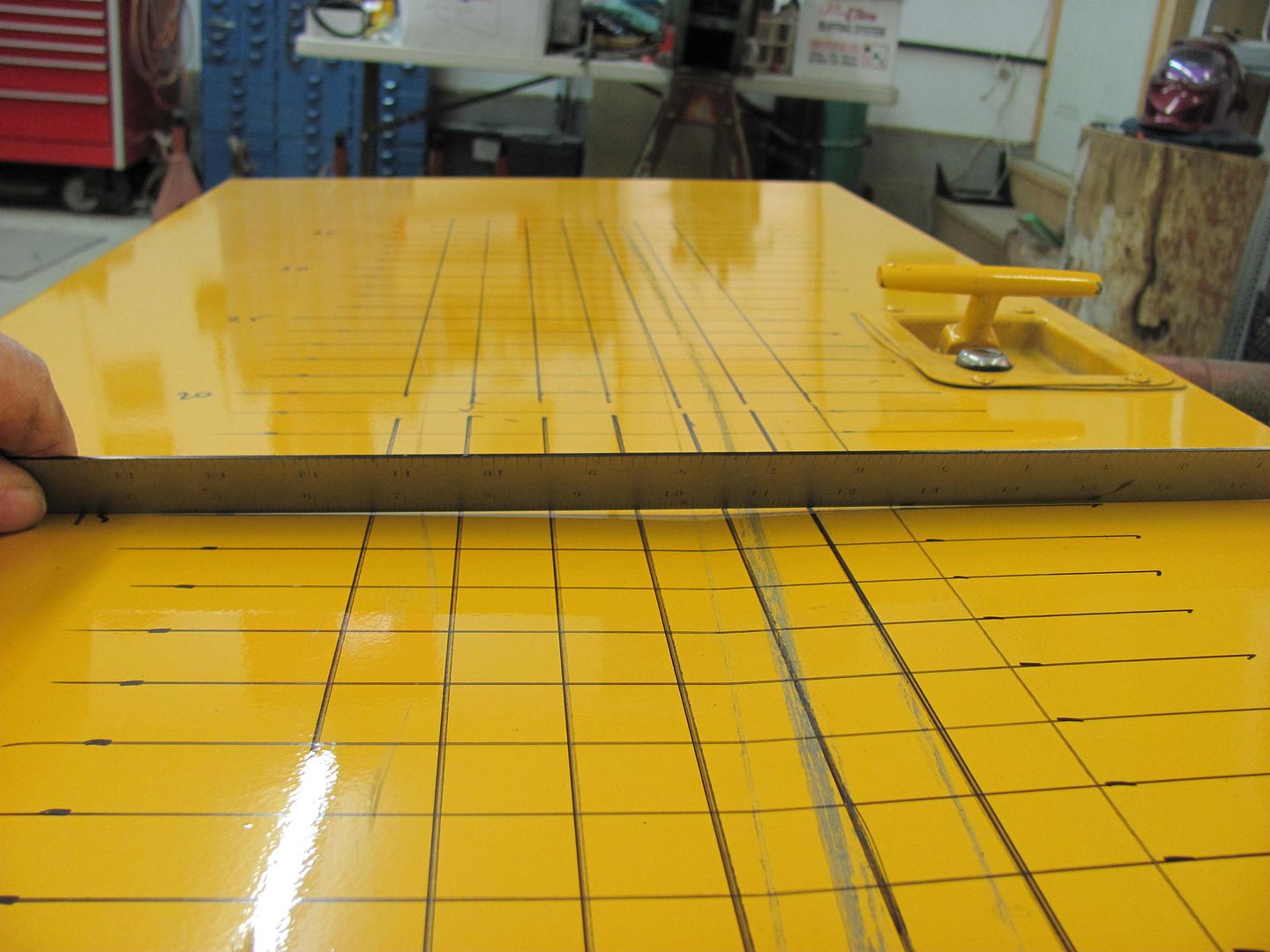

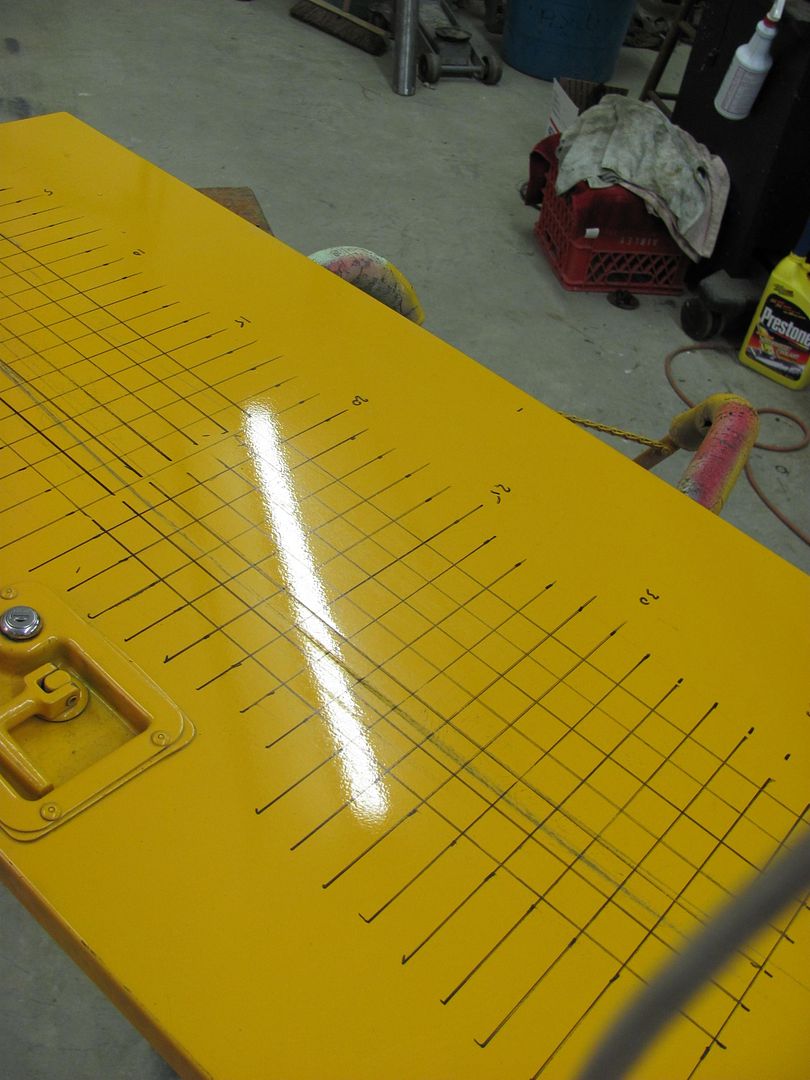

As the "donut dolly" is very closely matched in size to the hammer diameter, accuracy in locating the devices opposite each other is crucial. Depending on the panel you are repairing, this may be a challenge in itself. To keep the tools properly aligned and thus provide a more efficient shrink, I suggest a grid on either side, matched to identical starting points. Thinking back to the "springback" explained above in the formation of the dent, the objective in using these tools is to use just enough force that the high spot (the back side of the dent) is captured in the donut dolly such that once springback occurs the panel is flat/matches the crown of the surrounding panel, and not creating dents the other direction. We're looking for consistency and moderation in our hammer strikes...

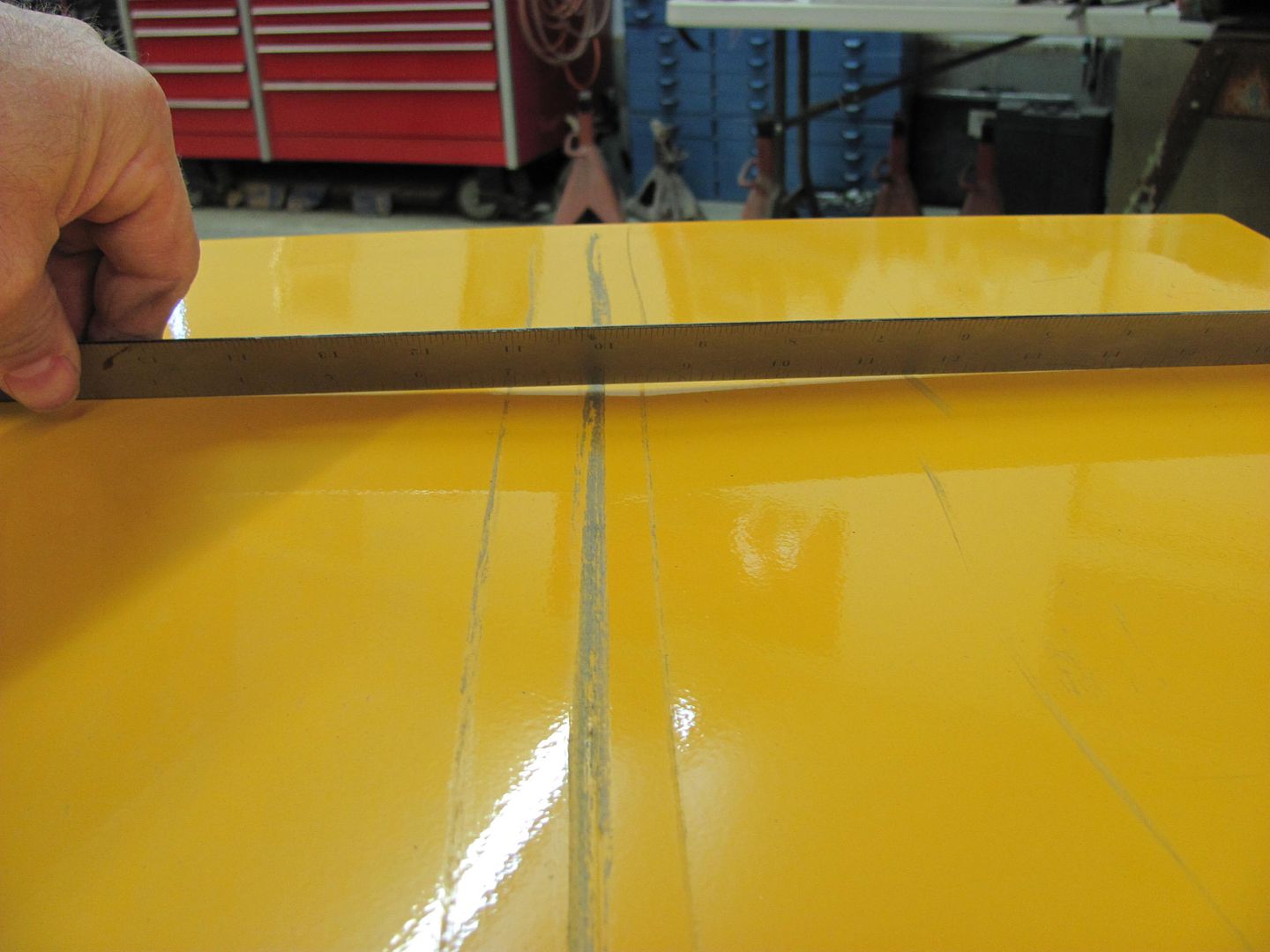

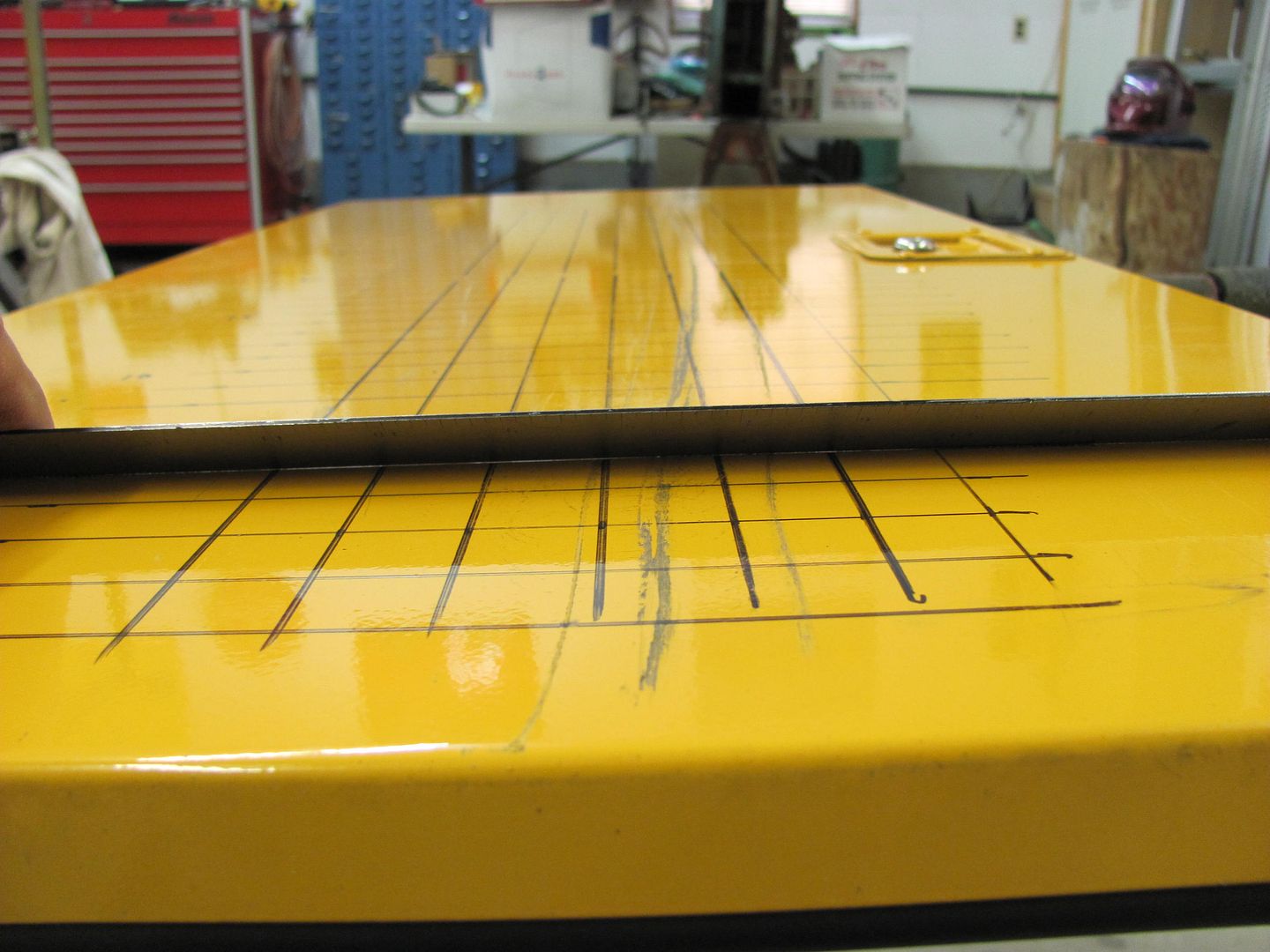

When laying out the grid, I numbered every fifth one just to keep better track of where I was. Some days you need all the help you can get. Different color sharpies could also help in keeping track of the lines. Also shown, using a straightedge for reference, is the damage before starting, located at grid 5, 10, and 15, to monitor any progress. The dolly is placed on the low side of the dent (the outside of the door) and the hammer is used on the high side of the dent (the inside of the door) so that the hammer strikes will force the excess metal into the donut dolly, creating a shrink.

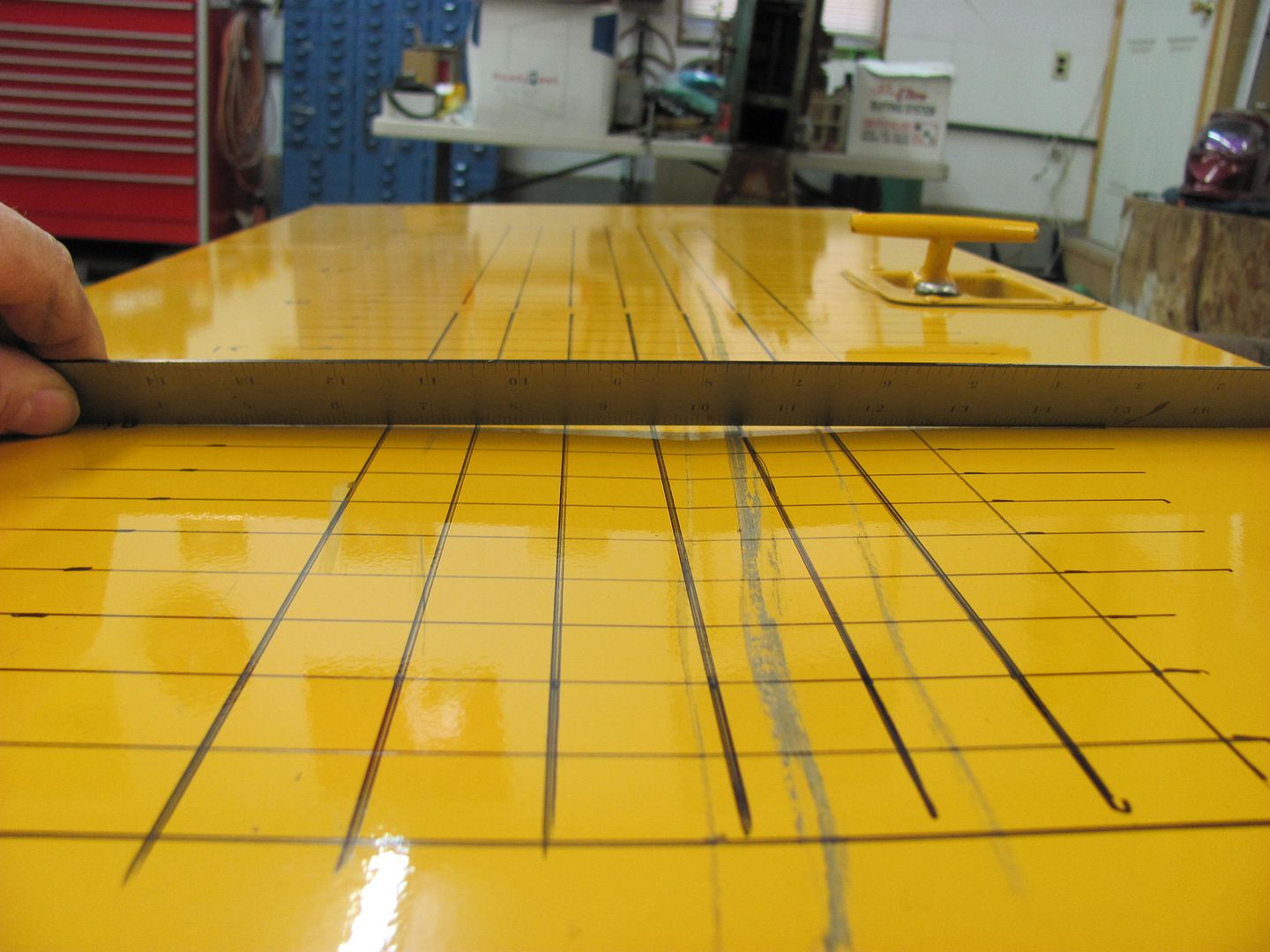

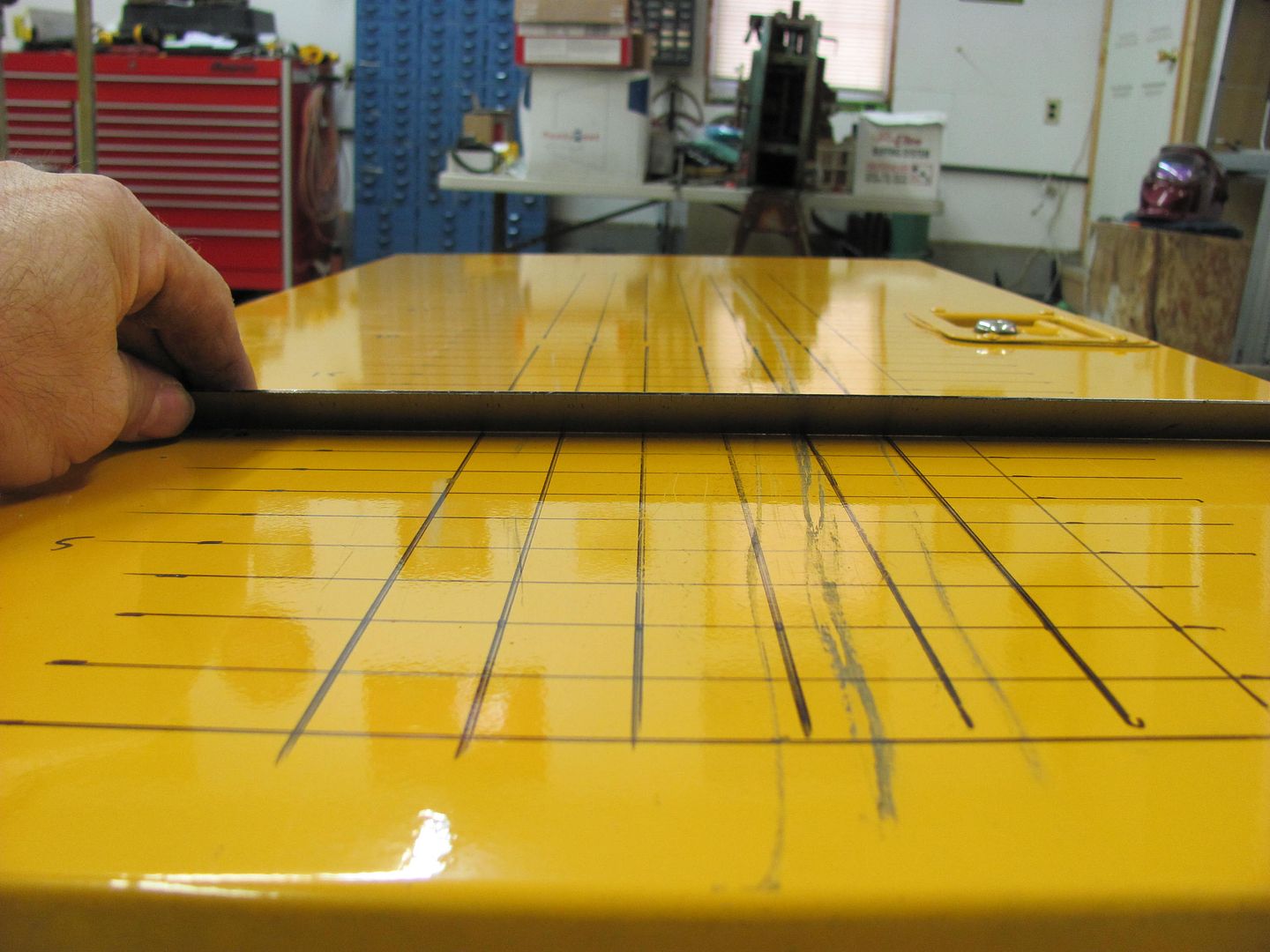

As I am working with a flat panel, I am able to use a straight edge to monitor the progress and see where additional shrinking may be needed. If you are using this process on a crowned panel, I would suggest making a profile template matched to the undamaged side of the car. Also, seldom does the crown on a panel remain consistent from one end of the panel to another, so it is very possible you may need different profile templates to accurately guage different sections along the panel.

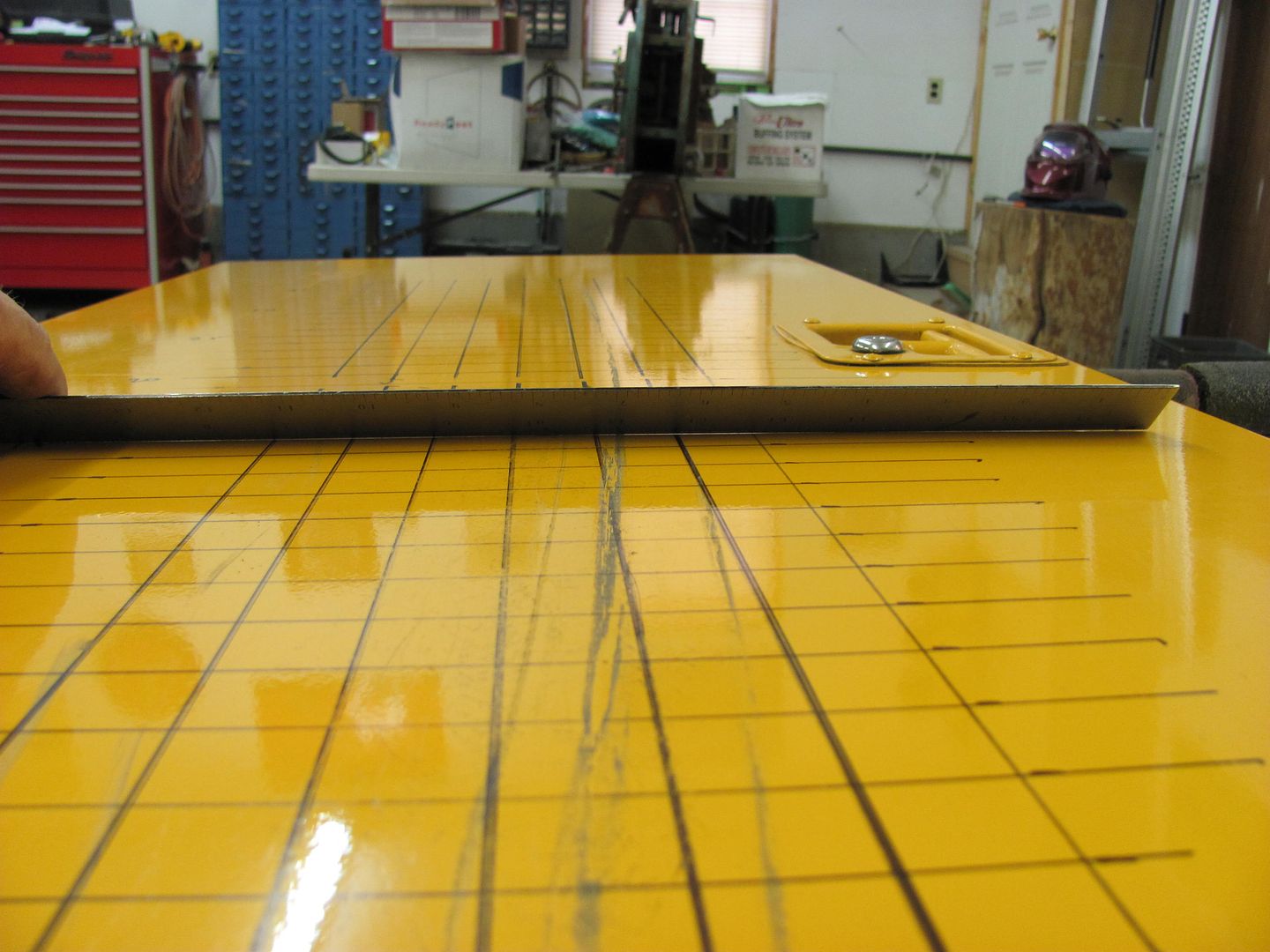

After about 30 minutes of work, here are the results, again located at grid 5, 10, and 15.

And the light reflection shows considerable improvement over the first pictures....

This is now at a point we could strip the paint off the door, and any remaining defects would be taken care of with high build primer. I have used this same process with other dents/dings/stretches from sandblast damage with similar success. As long as you have access to both sides, this is a relatively inexpensive option for dent removal.

1Likes

1Likes LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote

Down all day yesterday, up today, shit or get off the pot.

Where is everybody?