Thread: Hello from an old member

Results 1 to 15 of 553

Threaded View

-

02-16-2020 12:51 PM #36

Happy New Year to all!

I don't normally say HNY after January. But you guys are a special case

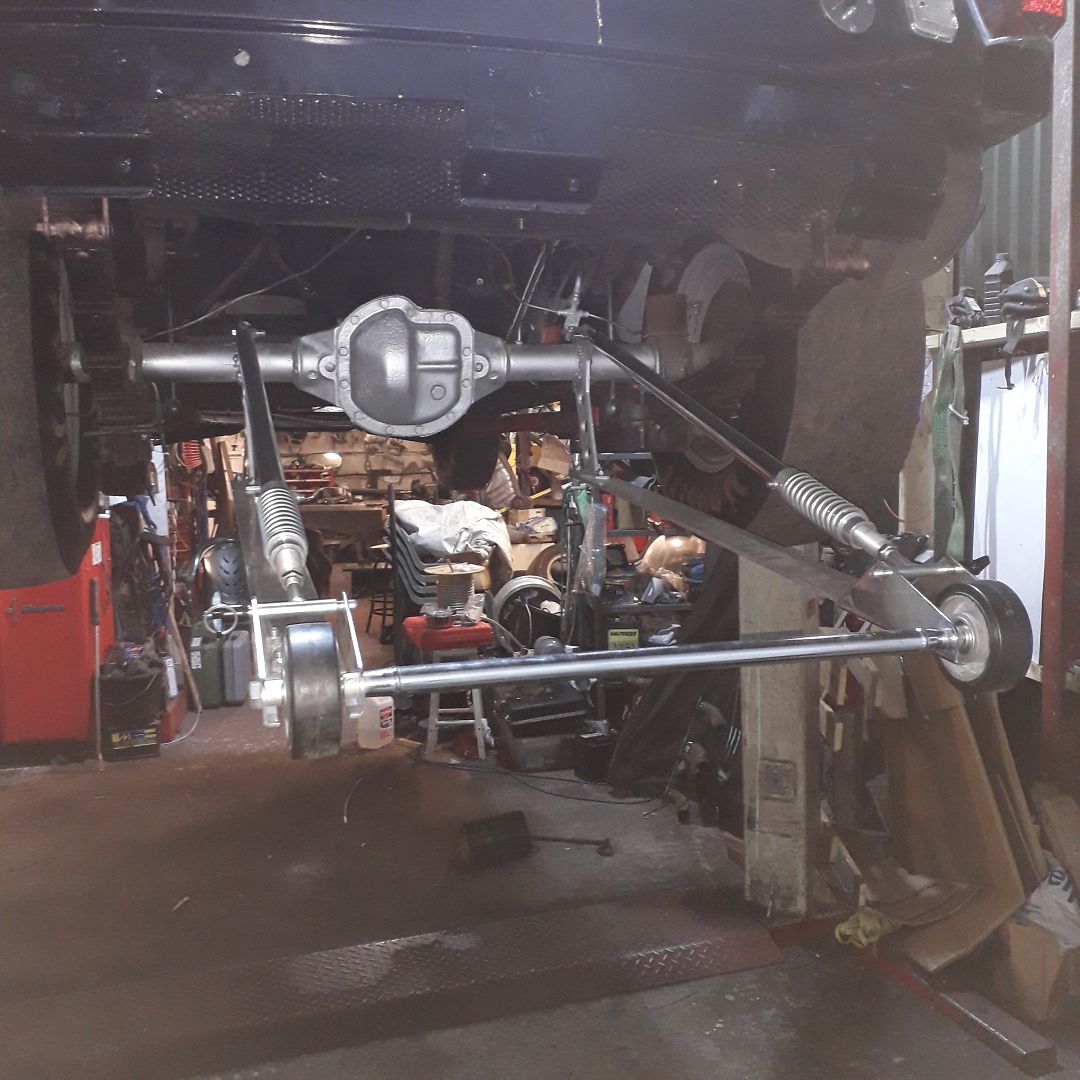

I got the wheelie bars fitted after some fettling. I made sure I levelled the ramp and that the floor behind was level. Before I fitted the bars I made changes to the slapper bar rubbers. The videos I have seen show the bars rolling upwards quite a lot. I have now made perches for the rubbers to sit on so they are 2" higher at rest. When the car is on the floor, the rubbers are slightly compressed now. The rear end can be bounced up and down on the springs so it still has suspension. I can also use the safety hoops over the springs to add more tension as required.

These are the hoops / large U bolts that I fitted to limit downward travel of the slapper bars so they could not hit the ground if such a condition occurred. This has also reduced the pinion angle between drive shaft and differential when the car is on the floor under its own weight.

I will say now that I have scanned the internet for any info I can find with regards to wheelie bars on leaf spring rear ends. I wasn't able to find much that was specific to my application, but I did gather enough info to help me on my way.

So I pre tensioned the slapper bars to try and simulate axle wind up on launch and then fitted the wheelie bars set to their lowest setting re wheel height after first raising the front of the car until the front suspension had unloaded with around 4" of air under the front tyres in an attempt to simulate launch conditions before the wheelie bars wheels touch down.

I'm sorry this is going on a little Guys! Please bear with me. I'm finding this part of the work very interesting for sure.

SO! with the wheelie bars now welded to the axle tube I set my rear tyre pressure at 15spi which is my race setting. I slowly lowered the car and noted that the bar wheels touched the ground at the same time as the rear slicks. As I lowered the car another inch or two I saw the rear and settle under the weight of the car and as the rear axle / leaf springs settled under the weight of the car the wheelie bar wheels lifted to 4" off the ground. So I think I now have a starting point to work from when I take it to the track over the next few weeks.

During the course of this work I re inspected the front suspension and found that the hard landings had caused a little damage. The inner wishbone mounts had touched down as I could see graze marks on the bush housings. The damage was not anything to worry about. But I then noticed that the front anti roll bar drop links had been damaged. One of them had the top clamp bent and the other top clamp had snapped the weld. I bought new links and added some tack welds to the top links. I then decided to test my welding of the wheelie bars mounts the only way I could think of ! I placed 10" wooden blocks under the wheelie bar wheels and lowered the 2 post lift onto the blocks. The lift dropped to ground level and the rear of the car was off the ground with front suspension fully loaded. Myself and a friend then sat in the boot and bounced up and down as best we could for several minutes. The wheelie bar springs took some of the load until they locked up. Nothing broke. So I guess the welds should be ok?

I guess I will find out on 23rd Feb IF its not raining at the track. I then have 1st March as the next test day.

I will report back when I have done some testing

Regards to all

Pel

264Likes

264Likes LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote

I'm happy to see it back up, sure hope it lasts.

Back online