Thread: Hello from an old member

Threaded View

-

05-06-2014 01:45 PM #11

Thanks for that advice

I can re torque before I race next Sunday.

I took off the rockers gear last night and went to the machine shop this afternoon. I explained to my friend that I needed to remove the adjuster stud that I glued in with loctite permanent !!

The trouble is that the stud is so darn hard that I didnt want to try an easy out as I didnt think it would dig in and grip. And if it did, it may just snap off and make things worse. I knew that I could heat the rocker in the oven to soften the loctite, but I had no way of unscrewing it

My good friend looked at it and said "so whats the problem" ? I said, "I need to be able to unscrew the stud but there is no way I can grip it" He said, "just use an allen key" I said, "how the hell can I use an allen key to undo a hard steel stud with no allen socket in the end?" He said, "come with me young Jedi" Ha Ha"!!

He then took me to a machine in the corner of his shop and started to mount my rocker in a clamp? He then fitted what looked like an allen key into a chuck? He then pressed several buttons and twiddled several knobs on this strange machine, which looked like a milling machine ??

What happened next had me watching with my jaw dropped. The table under the chuck was submerged in some green oily stuff as the sides rose up from around the table and this green stuff flooded the rocker. Then the chuck moved down on its own and a sound like a geiger counter came from a speaker unit on the wall. Then magic started happening under the oily fluid as I saw tiny lightning bolts and bubbles rising with puffs of smoke coming from the bubbles as they burst on the surface of the fluid?? OK!! So maybe I'm the only person who has never heard of spark etching

What a fantastic contraption this machine is. I WANT ONE !!

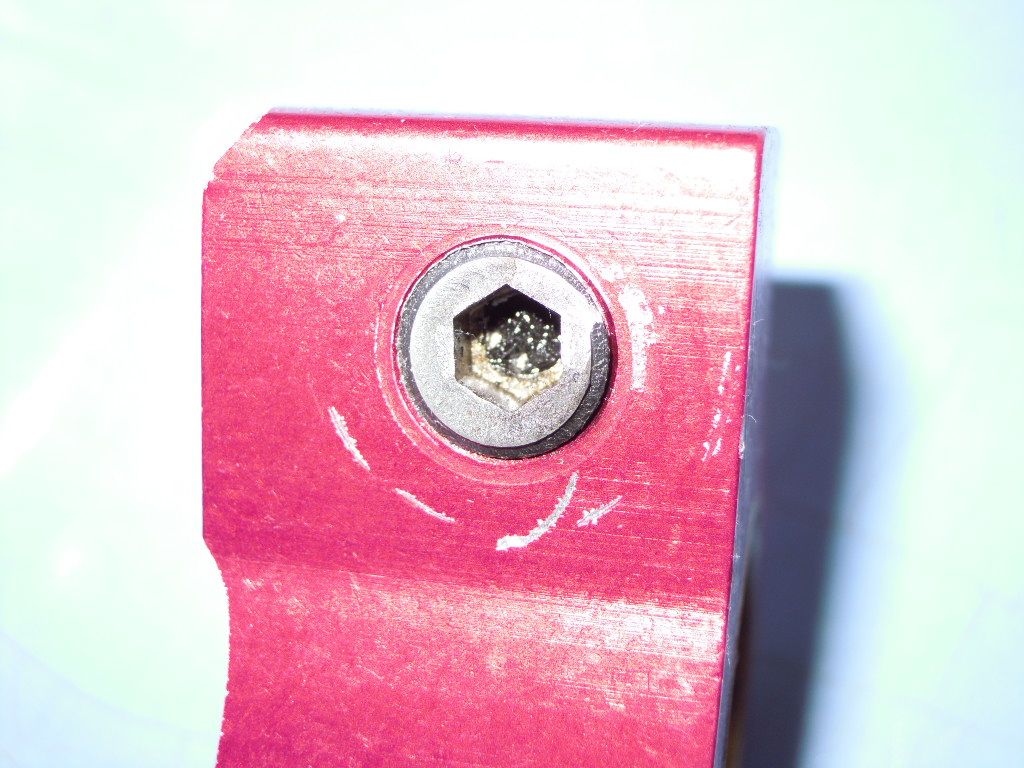

By the time the kettle had boiled and our tea was ready the machine beeped and the magic fluid drained away. Then Geoff unbolted the rocker and this is what I saw....

And this is what I started with !!

Holy Moly!!

Then it was back home to put the rocker in the oven for 20 mins at 220C which allowed me to do this...

HOORAY!!!!

Its 9.20pm here and I'm just back from dropping the rocker through the letter box at the machine shop so Geoff can get busy tomorrow re drilling and tapping to fit a 7/16th unf adjuster from a pro comp chevy rocker. The Kenne Bell adjusters are smaller. My friend with the slingshot has a full spare set of chevy rockers for his engine and he told me to go to his garage and help myself to some spares as he wont need them anytime soon. At least this will get me rolling for the weekend. I have put the word out to my Drag Race buddies and I now have an offer of a used set of KB rockers for very cheap money to put on the shelf. I will only use the pro comp modified rocker for the short term until I can fit a used OEM rocker.

So I can now be out for a grudge race this Sunday I wont win, I never will win against this car. But its fun trying as each time I turn up to race this guy every year I surprise him a little more. He runs a Chevy Monza which is his Drag School car and its very quick. We race on an unused runway at an old airfield. The surface is rough concrete and its a given that you always run at least 1 second slower on slicks than you would run on a prepped Drag Strip. Last year I ran a 10.6 @ 130 something to his 10.3 at 153mph. He toys with me to about 1000 feet and then puts the pedal down just before the finish

I wont win, I never will win against this car. But its fun trying as each time I turn up to race this guy every year I surprise him a little more. He runs a Chevy Monza which is his Drag School car and its very quick. We race on an unused runway at an old airfield. The surface is rough concrete and its a given that you always run at least 1 second slower on slicks than you would run on a prepped Drag Strip. Last year I ran a 10.6 @ 130 something to his 10.3 at 153mph. He toys with me to about 1000 feet and then puts the pedal down just before the finish

I really enjoy this annual race as does Paul who runs the Drag School.

https://www.youtube.com/watch?v=jvrk...iZ--GyG4tfRrjw

264Likes

264Likes LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote

John's ride to the cemetery, his beloved Billings OK bus, The Baby Elephant!! Traveling in style!! As his service was starting I couldn't figure out what the music was, heavy on a flute in a jaunty...

John Norton aka johnboy