Thread: 55 Wagon Progress

Threaded View

-

10-26-2013 07:29 PM #11

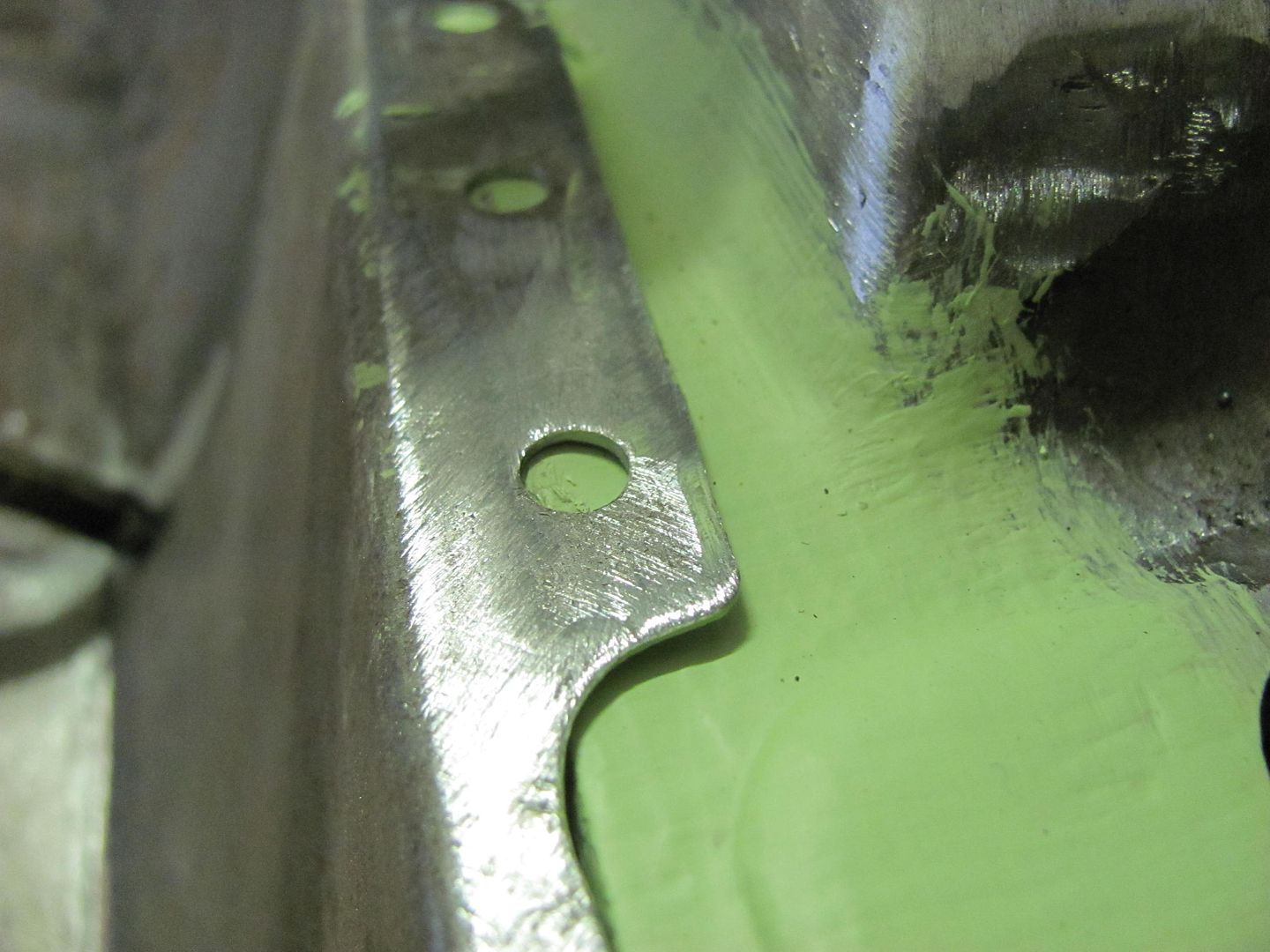

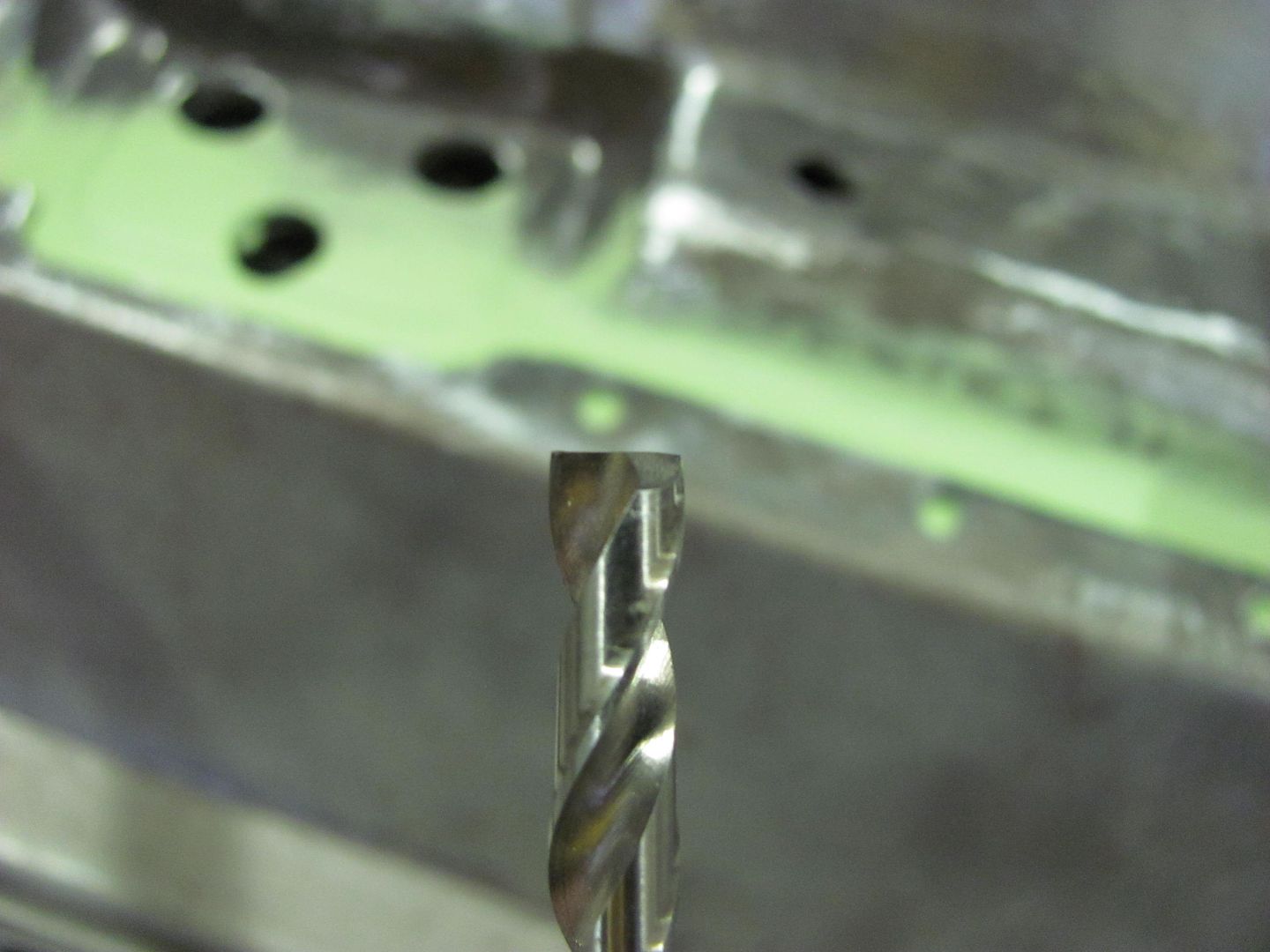

Thanks for the question. I am more of a proponent of epoxy over using weld through primers.. I typically will use epoxy between panels where weld through may be an option, and use a modified bit to clean out the plug weld hole:

This is the same size drill bit I used for plug weld holes that has been flattened and backfaced with a roloc sanding disc to resemble an end mill cutter.

This shows how it works, cleans the paint from the metal surface, but having a flat face on the cutter, it doesn't affect the metal as a regular drill bit would. Notice most of the "chips" are paint....

And welded......

Where this pinch weld seam you referred to will be on top and less prone to water intrusion, it will be painted and sealed inside the cavity prior to welding the outside panel on. Where the lower seam will be more prone to water intrusion and rust, it will get some epoxy primer between the two panels prior to welding using the method shown in these last few pics....Robert

3390Likes

3390Likes LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote

".......So sanded it all down and resprayed. ......" Been there. done that on a couple of paint jobs over the years. Usually took me a couple of days to get over being mad before I started...

Stude M5 build