16Likes

16Likes

Thread: Ranger truck bed repairs

Results 1 to 7 of 7

Threaded View

-

06-13-2016 09:29 AM #1

Ranger truck bed repairs

Spent this past weekend replacing the floor in my Niece's Ford Ranger pickup.. To recap, the truck was very solid other than an area of the bed that showed some repairs had occurred:

Looking at this area from the bottom side, in addition to the sign material added by the last hack (owner?) as a platform for Bondo, we see that one of the manufacturer's bright ideas of heat control above the muffler also was of a nice fibrous textile that also retained moisture well..

They had researched many used beds, most the wrong color, others rusted farther along, or salvage yards that liked to set beds on the ground to roll the quarters under nicely. Further research reveals that the bed floor was still available, so it was bought from the local dealer, along with one of the cross members. (the only cross member still available) I figured we had enough technical know-how to fabricate any of the others, if needed. Plus, since they were talking about getting Line-X installed, there was no need for a finish coat, SPI epoxy should serve fine by itself.

Bed floor and OEM cross member sprayed in Epoxy..

Taking a better look just prior to removing the bed, looks like this was just shy of Flintstone status.

Bed removal

Temporarily placed on sawhorses, then lifted with a winch, lowered onto furniture dollies, and left tension on the winch for safety precaution..

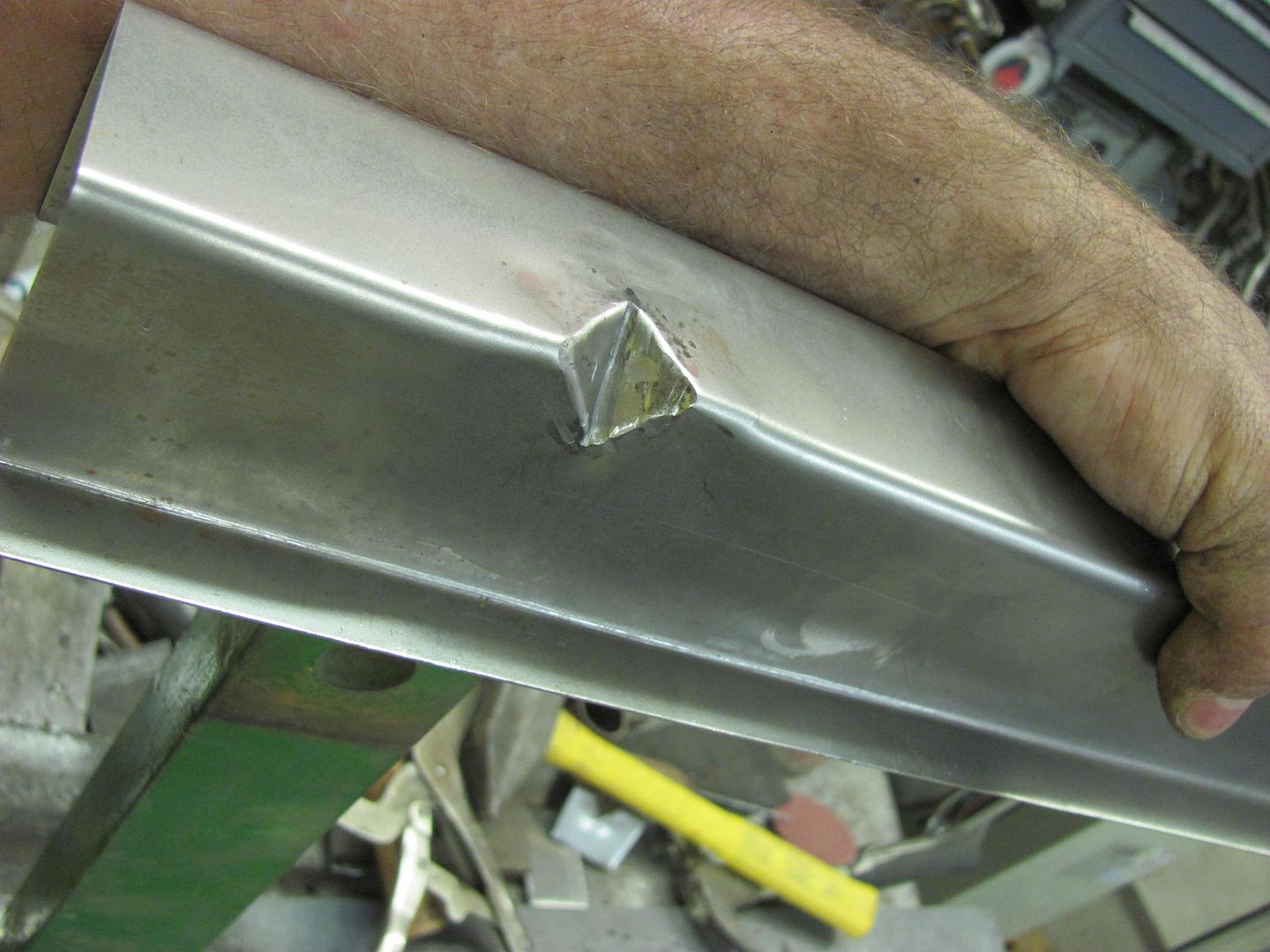

More of the fine repairs previously done. It's hack work like this that makes a job that much harder...

We had one cross member we needed to fabricate, and the drawbar for the JD is modified to add some stiffening/strengthening details..

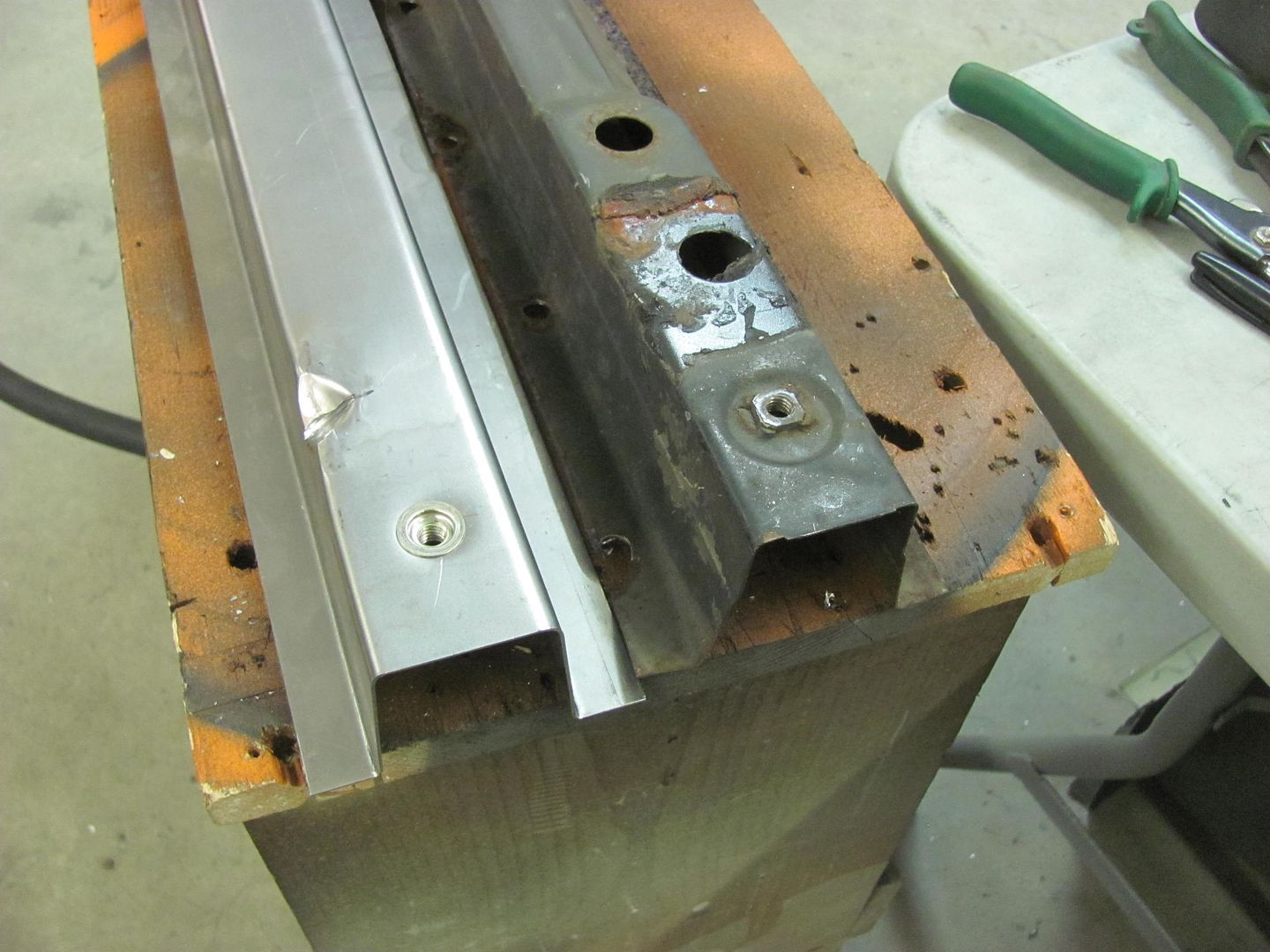

Used some AVK style rivet-nut fasteners for anchoring the wheel opening braces..

All spot welds were drilled out, and will be used as plug weld holes for re-assembly..

Prior to assembly, some SPI epoxy was brushed onto the parts for better rust prevention in the future..

Remaining flanges on the bed were prepped and received a covering of epoxy as well..

New bed floor seemed a bit wide going in (prior to welding) so we marked center of both the opening and the floor, then aligned the marks and clamped in place. To clean out the paint inside the plug weld holes from the adjacent panel, a modified bit was used.

Being a flat cutter, it does more paint removal and less damage in metal removal, as shown here:

Welds ground down and all the bare spots touched up...

Re-installed onto the truck frame, no Bondo, no mesh screen, no plastic......

....and no Flintstone holes..

After the SPI epoxy cures for a few days they should be scheduling for the spray in bedliner..

Robert

LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote

To the top

Where is everybody?