Thread: 1965 Fairlane build

Threaded View

-

02-10-2012 11:33 AM #10

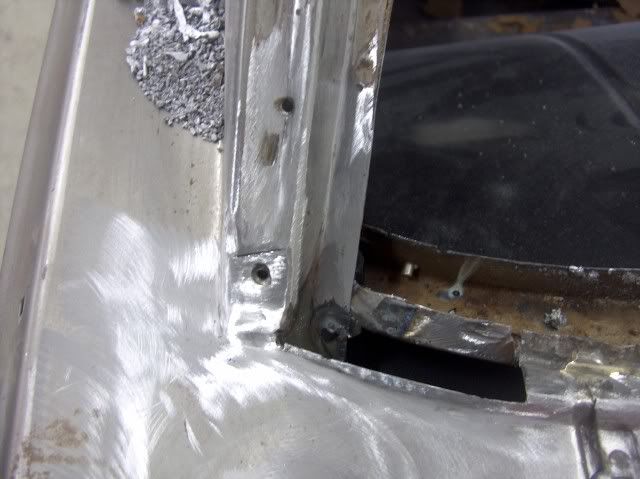

Noticed this was lurking while cleaning up the rear window channel, hoping to get a step closer to primer.

The first step I normally take is to use the pick to check the surrounding area for any hidden damage, and decide how far to take the opening. Once you find solid metal, the next consideration is the ease of dressing out the repair. It's easier to grind and sand on an outside radius than an inside one, so that is factored into the cut size. Sometimes you don't have a choice, but best to make it easier on yourself when you can!

The channel is actually made in two pieces. The spot welds in the pinch weld area are removed from the top layer to remove the damaged pieces. The vertical piece actually travels down beyond the bottom of the window in this case, so that will be installed first. A new piece is cut out and bent to fit, and final sanding/grinding to get a tight weld joint.

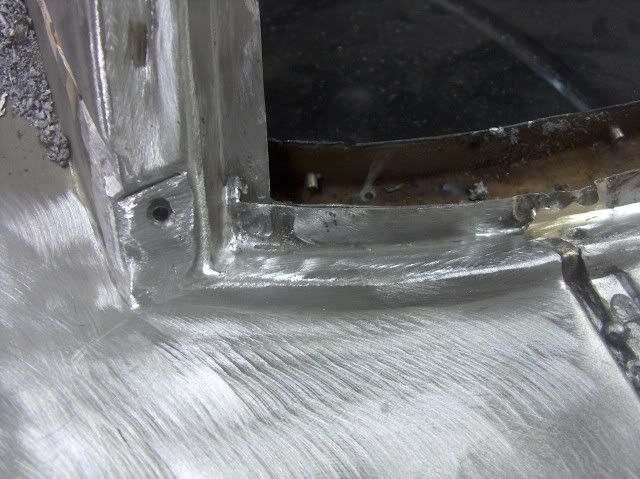

The bottom piece has a radius in two directions, slopes up and in.

The outer (rear) radius was hammer formed after the shrinking and stretching was done. Then trimmed to fit and welded in place.

The inside corner joint was welded and cleaned up with a ball nose burr grinder, to keep water traps to a minimum.

6Likes

6Likes LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote

Right after I posted yesterday it was down again, I don't think it's getting better.

Where is everybody?