Hybrid View

-

03-14-2016 08:01 PM #1

Had a question about placement of the thinning groove, so I thought I'd post the results of the test sample...

Originally Posted by WoodsTruck

Originally Posted by WoodsTruck

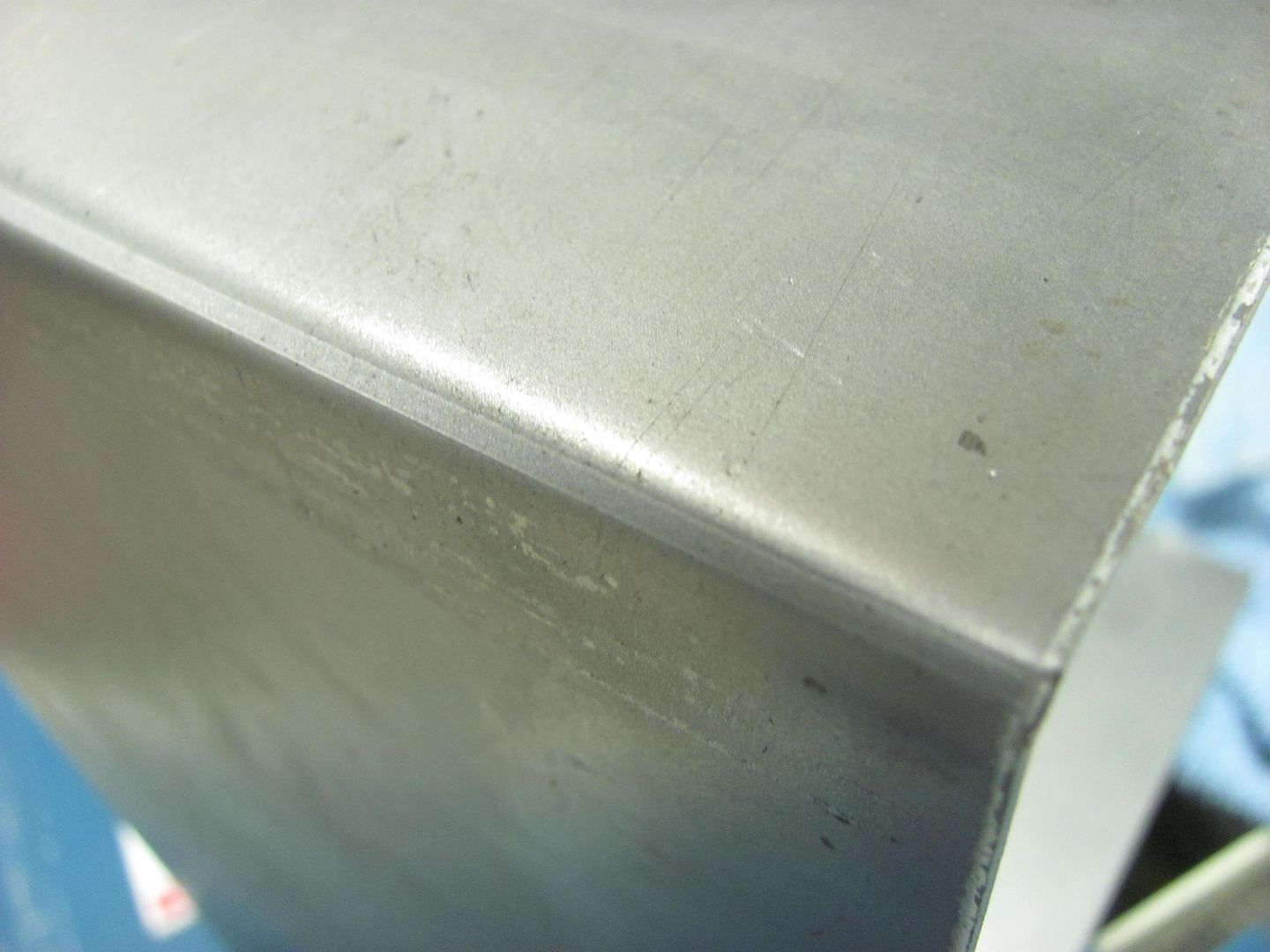

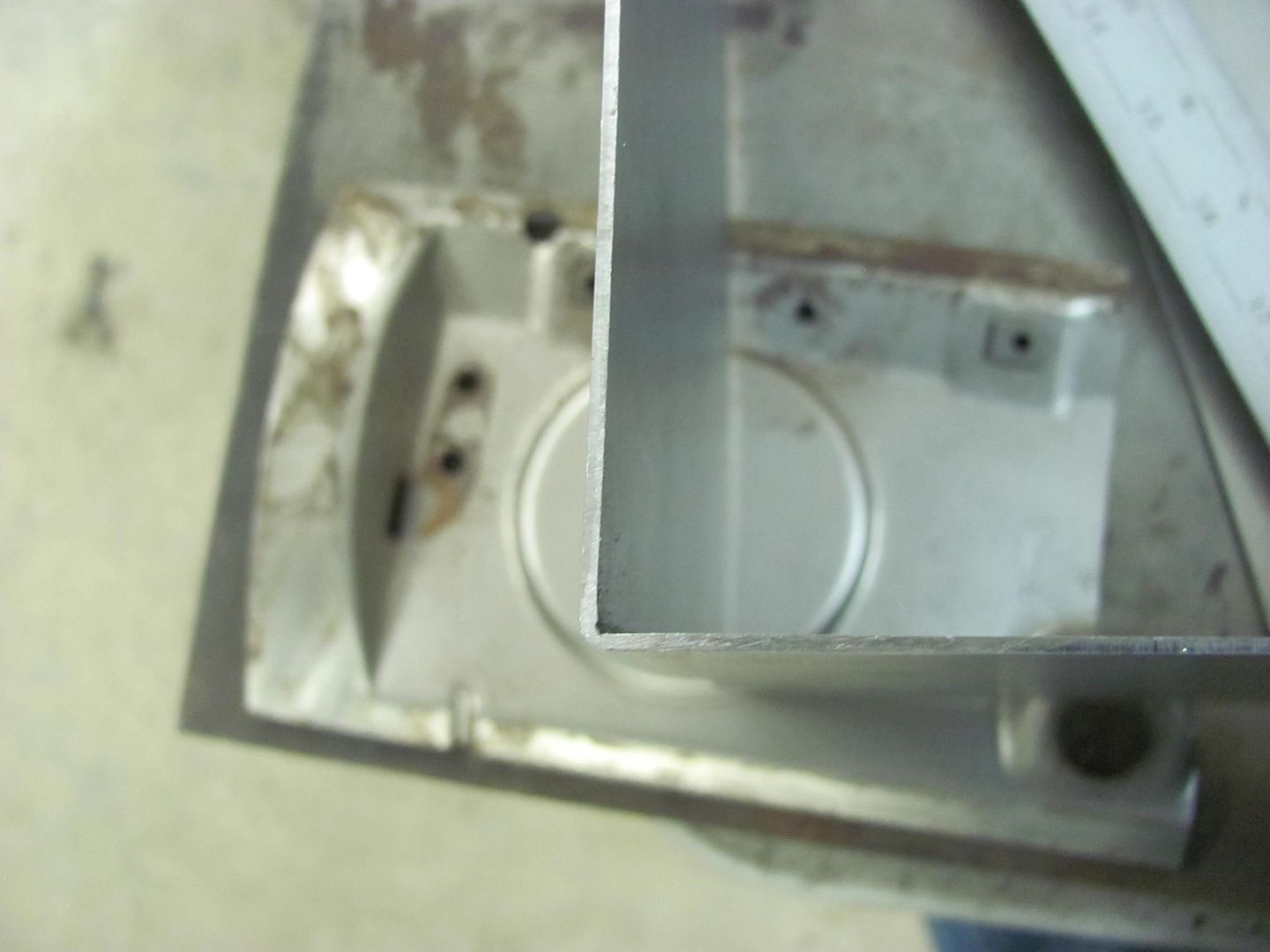

Here's the test from tonight. The 16 ga thickness measured out to about .057, at the "thinning" groove it was .053, so we lost about .004 in thickness, or less than 10%. Put the thinning groove on the outside for this bend, it tended to stretch the deformity back out again where it looks like it could be more readily cleaned up with a file..

So where the bending process allowed the groove to stretch back out....

...it also gave us a wider radius than when the thinning was placed on the inside of the bend...

So I'd say to use placement based on if a tighter radius is needed or whether you need it dressed outRobert

-

03-15-2016 07:11 AM #2

Roger

Enjoy the little things in life, and you may look back one day and realize that they were really the BIG things.

260Likes

260Likes

LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks Reply With Quote

Reply With Quote

To the top

Where is everybody?