Thread: Lets see your tin work...

-

04-23-2013 04:53 PM #1

Lets see your tin work...

Thought it might be interesting to see what tin and aluminum work is being done out there? Im always looking for ideas and things to do in Sheet Metal and Aluminum. Feel free to add to the thread with your work or ?

I will start this off with one of my latest projects...

Just recently finished up some aluminum work on this Ford Cobra. Mr Customer wanted something unique so this is what I came up with.

Polished aluminum intake, powder coated engine surround, Powder coated gas tank cover, Polished body through for the headers, and Polished rock guards for the rear fenders. And a bunch of little things that aren't seen.

duplicate account

-

Advertising

- Google Adsense

- REGISTERED USERS DO NOT SEE THIS AD

-

04-24-2013 05:38 PM #2

That metal work looks great, and unique as far as I know but I'm no Cobra expert. But the way it looks inside the snout with the oil cooler underneath is very nice. I like the underhood engine covers also, but less of a fan of that look since I like the look of a lot of the hardware, especially after a little effort at simplifying and maybe even tucking stuff.

It reminds me a little of the aluminum undertray I have on my Supra except that my undertray is not what I would call "tin work" since it's just a flat sheet cut to size. I integrated it with this carbon fiber front lip since it has a low central opening; with a decent sized front mount intercooler the air to the radiator and oil cooler is somewhat obstructed so with this undertray and by raising the intercooler a couple inches I was able to channel air into the lower lip opening and under the intercooler to the radiator and oil cooler. The benefit is very noticeable in engine coolant temperature. Since the lip also has the two little side openings, I used those to scoop some air that I duct to my front rotors ...really made a noticeable improvement in brake cooling on the track; brakes were already excellent but now they never fade.

A little more simple "tin work" are the aluminum intakes for the two turbos; I have fine mesh stainless screen cones inside each to catch larger critters; I realize it doesn't filter air as well as a real filter, and I have a good filter setup too, but I like to hear the turbo noises Here's some pics of this setup:

Here's some pics of this setup:

CF lower lip with openings:

undertray also showing brake ducts

inside lower front opening showing air passage under intercooler

air intake scoops

front brake air scoops and broadside view of undertray attached to front lip

Now in spite of what some of you may think, maybe because I'm an older guy with a different perspective compared to young import car owners, I still consider the Supra as my sports car - hot rod so I'm not shy about posting it.

On the more "conventional" hot rod my '32 Brookville roadster, my buddy actually did the "tin work" on my bomber seats which you can see below; he also did an aluminum air scoop and box around my tranny cooler which sits horizontally by my oil pan but I don't have a good pic of that.

The bomber seats are getting upholstered next week:

Nick

Brookville '32 hi-boy roadster

TriStar Pro Star 427 CID

-

04-24-2013 05:57 PM #3

I can't think of anyone here who doesn't enjoy seeing a race car! And the yeller car is ok too!

-

04-24-2013 07:08 PM #4

-

04-24-2013 09:14 PM #5

-

04-24-2013 09:18 PM #6

-

04-24-2013 10:28 PM #7

-

04-25-2013 10:29 AM #8

That looks like some cool parts, pro. The car and chassis also look very interesting. Are those two things for air to/from a water-to-air intercooler for a big turbo V8 drag car?Nick

Brookville '32 hi-boy roadster

TriStar Pro Star 427 CID

-

04-25-2013 01:11 PM #9

Wow! You guys are good!!

Lynn

'32 3W

There's no 12 step program for stupid!

http://photo.net/photos/Lynn%20Johanson

-

04-25-2013 06:31 PM #10

-

04-25-2013 07:21 PM #11

Very nice work!!! Sheet metal work is not all that expensive (materials) to do, but it is very labor intensive. When it's done right, as these examples are, it becomes a work of art! I've got to use a compass and a ruler to draw stick people and with a paint brush in hand I'm considered armed and dangerous so I guess sheet metal work is as close to art as I'll ever get!!!!!

Making panels and pieces with fiberglass and other composites is IMO right up there with sheet metal in the amount of work required and the results!!!Yesterday is history, tomorrow is a mystery, Live for Today!

Carroll Shelby

Learning must be difficult for those who already know it all!!!!

-

04-25-2013 08:07 PM #12

-

04-25-2013 09:06 PM #13

Hey Pro I have a Model A I started to rebuild after it burned to the ground in1974. I still have a ways to go!

I still have a ways to go!

Thanks for the props guys but its like anything else... if you do it enough you get good at it. The trick is to keep trying new things and stretch the limits. It is more artsy than a lot of metal working. This is a dash insert I did a while back for a 74 Nova... Different and fun for me.

duplicate account

-

04-26-2013 04:19 AM #14

The quality and craftsmanship that is produced by the people who frequent this site is amazing. I have a few friends who are in this category and am always in awe of seeing what they can do.

-

04-30-2013 08:36 PM #15

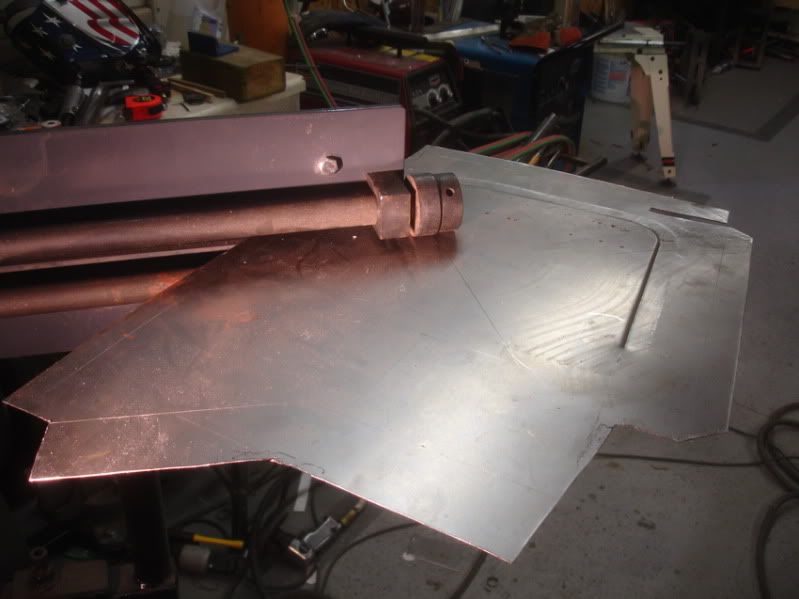

I started bending up this roll pan for my Model A. Someone saw it and wanted so I sold it and shipped it off. I now am bending up 7 at a time and letting them fly. Still havent got one for myself! Maybe one from the next batch will find a home on it. Not for everyone but I always thought the A's looked un finished in the back.

Last edited by M.T.1; 05-01-2013 at 09:50 AM.

duplicate account

13Likes

13Likes

LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks Reply With Quote

Reply With Quote

Hoirodders.com

Where is everybody?