-

04-04-2009 07:27 AM #1

Bending axle tubes when welding on brackets.

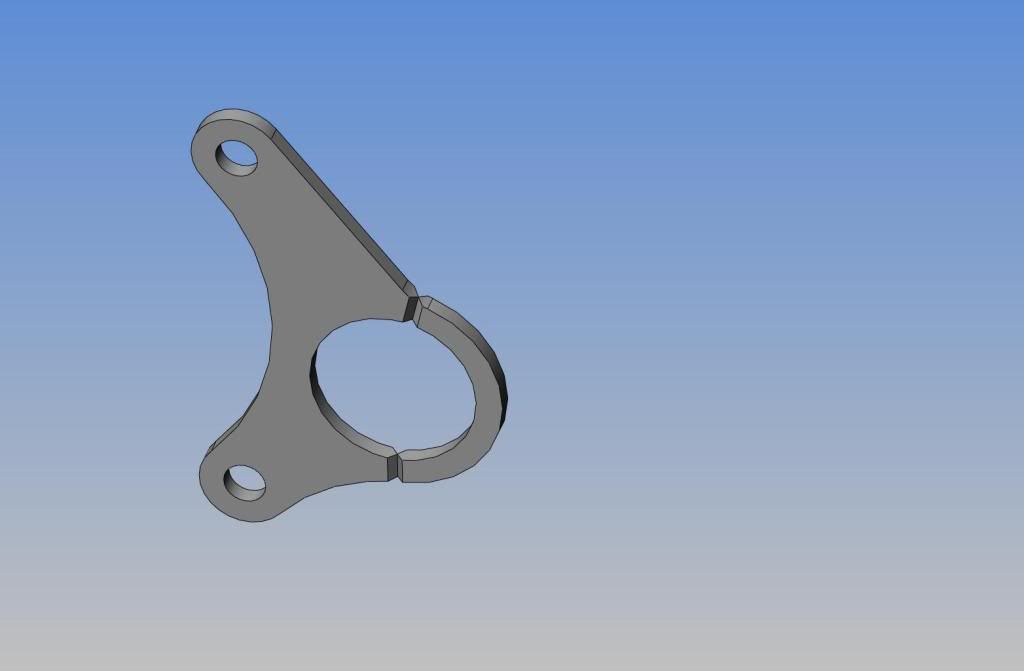

I have never had a problem with welding a bracket onto one side only of an axle tube, but then again, all the rearends that I have ever used were from donor cars that had a zillion miles on them already, and had a lot of wear on them. This meant that probably if the axle tube did bend a bit, there was enough slop in all the clearances that a slight bend would go unnoticed. However, if you are concerned, then make your brackets like this 3D model I just created. Make it a full 360 degree bracket, then split it as shown to get it over the axle tube, then tack it back together. Position it correctly, then weld all the way around a full 360 degrees in short "bursts" alternating from side to side as you weld. The thing that causes axle tubes to bend is a lot of welding and concentrated heat on one side of the tube only. With a bracket like this, the heat is equalized all the way around the tube, so bending will be kept to an absolute minimum.---Brian

Old guy hot rodder

-

Advertising

- Google Adsense

- REGISTERED USERS DO NOT SEE THIS AD

-

04-04-2009 12:56 PM #2

Thanks for that Brian. If you do have to straighten the housing, here's a little help.....

http://www.crankshaftcoalition.com/w...ar_end_housing

-

04-04-2009 07:38 PM #3

yep thats a good way to go. i seen them bend some after welding to hard to say how much they were bent off the get go alot of the fords 9 s were used in trucks and you know they never get over loaded .before welding i check for bow if not bad i weld every thing on alot of the housing get new ends put on were i cut them to size if off less then 1/4 at the end i weld the new ends on with the jig in it so there true when doneIrish Diplomacy ..the ability to tell someone to go to Hell ,,So that they will look forward to to the trip

Welcome to Club Hot Rod! The premier site for

everything to do with Hot Rod, Customs, Low Riders, Rat Rods, and more.

- » Members from all over the US and the world!

- » Help from all over the world for your questions

- » Build logs for you and all members

- » Blogs

- » Image Gallery

- » Many thousands of members and hundreds of thousands of posts!

YES! I want to register an account for free right now! p.s.: For registered members this ad will NOT show

LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks Reply With Quote

Reply With Quote

I bought the 76 in August , but haven't been able to work on it. When I get a chance I'll post some pictures.

Corvette Resurrection?