Thread: Low cost homemade welding tool.

Threaded View

-

06-30-2007 08:34 AM #1

Low cost homemade welding tool.

We have all seen this tip mentioned on the forums, I thought I would put it in the "flesh." Weld won't stick to copper or brass. So, if you had a hole in metal you could temporarily put a piece of copper or brass behind the hole, weld into the edge of the hole with your MIG and literally fill the hole up without the weld falling thru. Remove the copper or brass and the back side will actually be as smooth as the surface of the copper or brass! It is a very neat trick and there are a bunch of tools you can buy for this purpose.

For example, I have a pair of "Vice grip" pliers with the copper backing built onto it. This is a very useful tool and like all tools, you just can't have enough. But it is very limited by the "throat" of the tool. If you have a hole out in the middle of a panel, it is worthless.

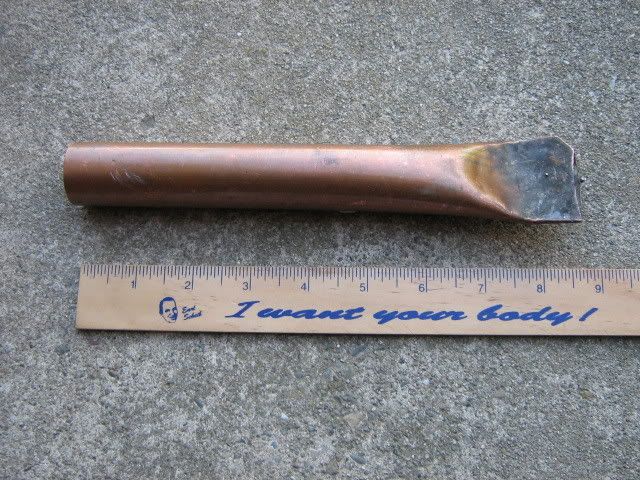

One day I found myself needing a copper backing, I walked over to a pile of pipe cut off a piece about 9" long, smashed one end down real good with a hammer and a new tool was born. This is 1" diameter but it could be made from about any size. It has a handle so I can hold it up for a fast weld were even my clamp would have worked. Or I can reach around the back of panels to weld a hole out in the middle. Works like a charm. It was free because I had the pipe sitting there but one quick trip to the hardware store and a few bucks (or less) and you can make one too.

Brian

Last edited by MARTINSR; 06-30-2007 at 08:47 AM.

"Fan of most anything that moves human beings"

LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote

Down all day yesterday, up today, shit or get off the pot.

Where is everybody?