Results 1 to 13 of 13

Threaded View

-

01-11-2007 02:20 PM #4

I usually won't make a move without at least modeling something in 3D. It is easy enough to do and I am working with "real" dimensions so the numbers are already in my head.

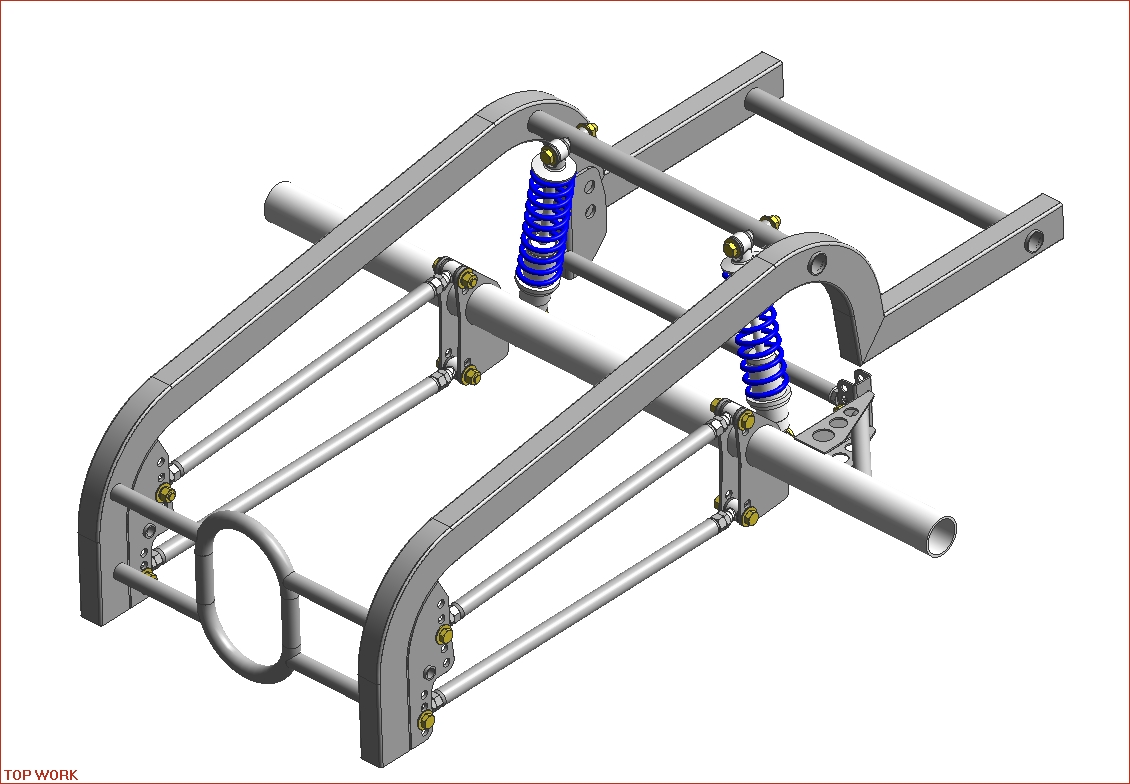

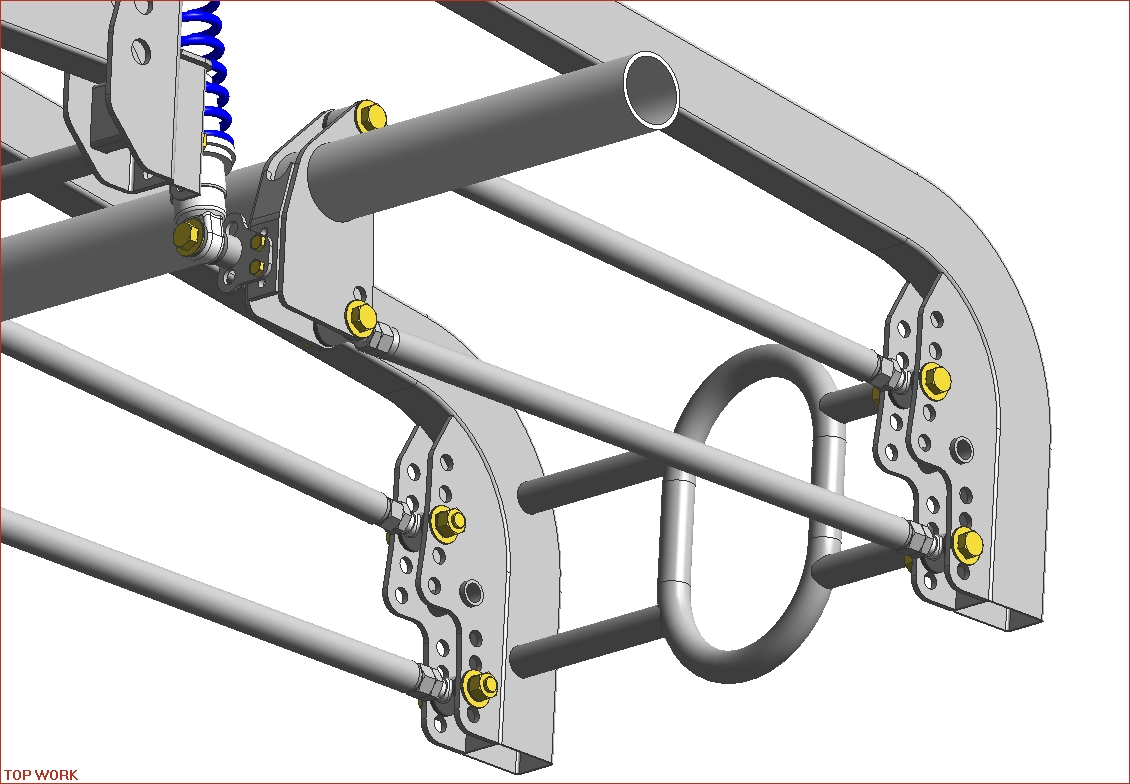

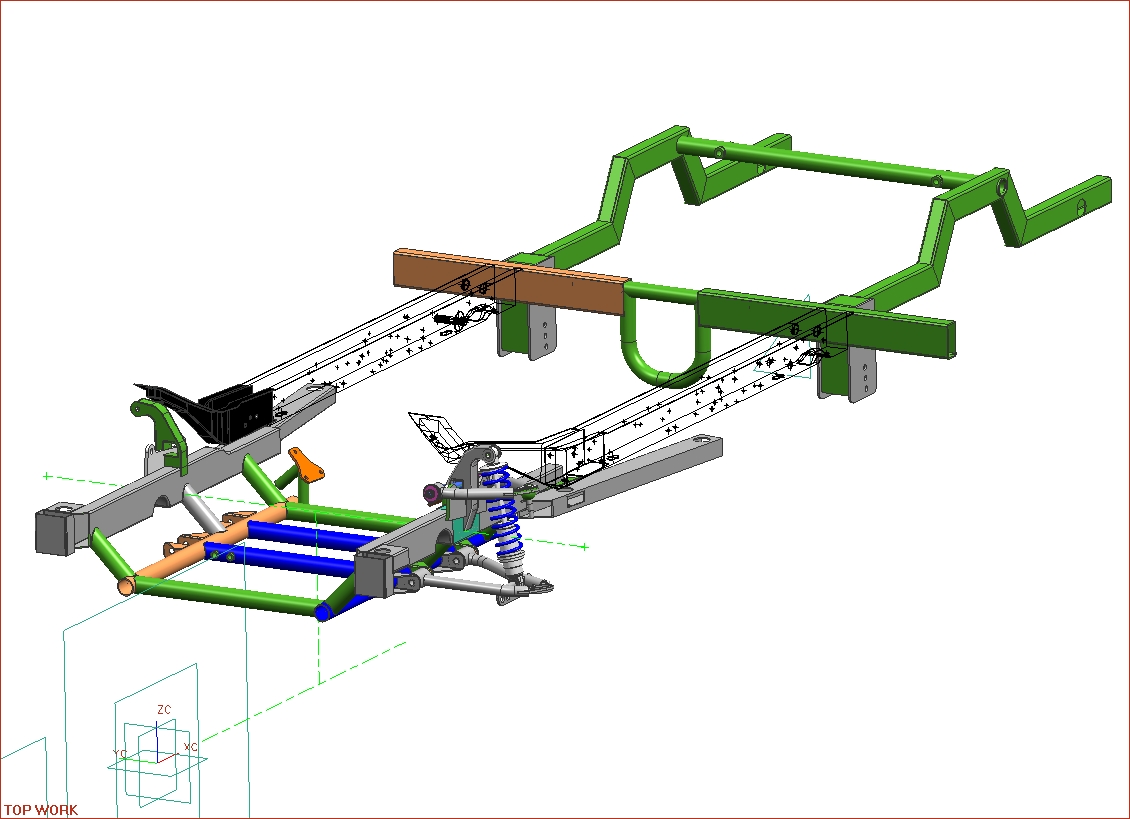

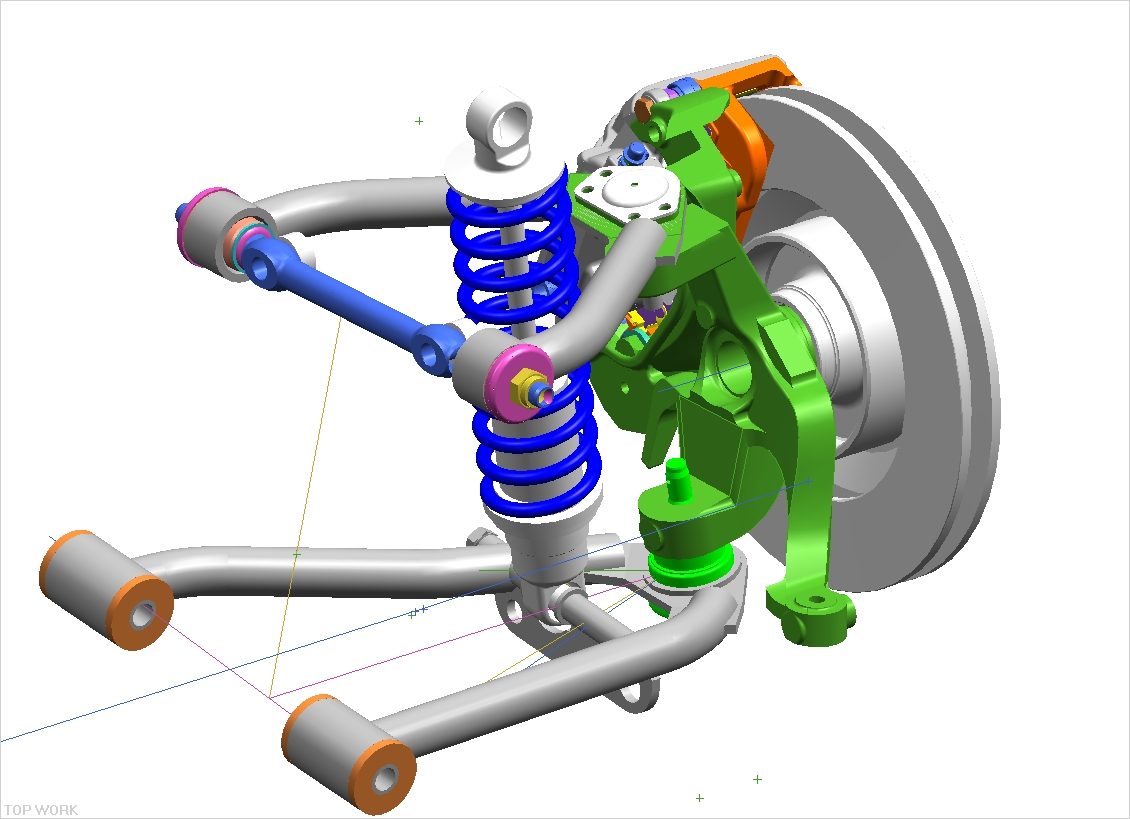

This is a 4-Link Rear Suspension I am designing for a customer.

The thing is, when the design is done I can file out .dxf files for all of the brackets and have them lazer or waterjet cut. That in itself saves a TON of time and I know the brackets are all the same. I have spent many days cutting brackets and it gets very tedious. If I put this suspension into production lazer cutting is the only way to do it cost effectively.

I have done the same thing with my Astro Van Chassis.

Look at the control arms. I can use this data to create welding fixtures when it comes time to assembly the arms. There are so many things you can do with the data ONCE you have it in 3D it doesn't make sense, too me anyway, to not do it this way.

It is always a good thing to know that, when you start cutting, the pieces will go together as designed. Unless I really screw it up there is no doubt it will work and look as it does on the screen.

MarkIf money is the root of all evil... Women must be the fertilizer...

Link to my BAD AST Build Thread:

http://www.clubhotrod.com/suspension...van-build.html

LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote

A belated Happy 78th Birthday Roger Spears

Belated Happy Birthday