Results 1 to 15 of 6479

Threaded View

-

07-04-2011 08:48 PM #11

Steel fab today, no bling.

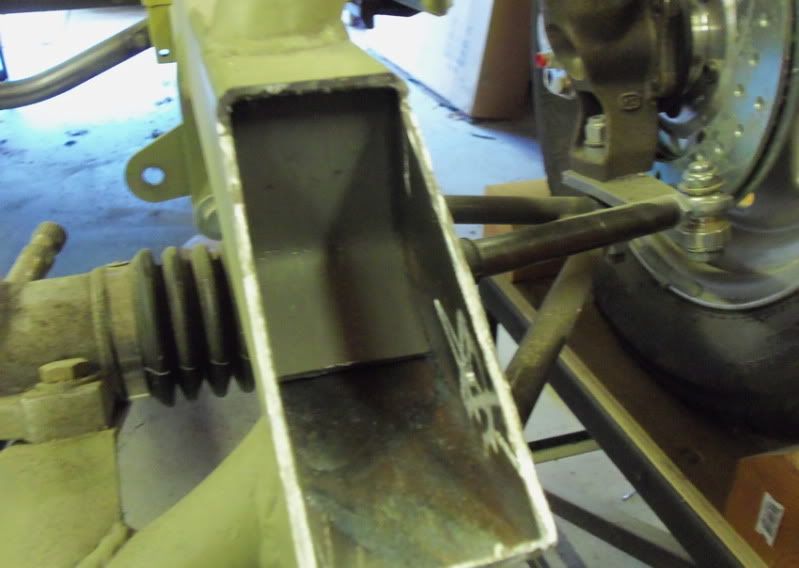

Got a little more done on the hinges. Made a jig to cut the frame horns off. Boxed in the rail to keep junk from getting down inside the frame. Welded them in along with some fish plates to weld the horns back on.

Got a little more done on the hinges. Made a jig to cut the frame horns off. Boxed in the rail to keep junk from getting down inside the frame. Welded them in along with some fish plates to weld the horns back on.

I had a little ooops. I spun some bushing bungs on the lathe, welded them in & when I tested it the hinge came out of the rail. The pins were supposed to keep the hinge in the rail but there was just enough clearance for it to slip by.

So I made up these little clips to grab the pin a little better. Ended up making clips for both pins. That meant the linkage would no longer fit inside the rail, so I made some c-channel out of square tubing for the bottom. Holes are for junk & water drainage. I'll have to add one on the top too. At least the hinge locks in place solid now, in both open & closed positions.

Got a few more parts to make & they will be ready to weld back on. The 3/4'' pins are for alignment during welding, eventually they will be replaced with 3/4" nylon bushing stock & a 1/2" steel pin. Got some black corian® cut-offs from a counter top place. Cutting that on the CNC to fill in the gaps between the rails & the hinges, so there won't be any metal to metal contact. Nylon & corian® should allow the hinges to slide smooth.

I hope this deal goes a little better from here on out. Hate those glitches.Last edited by pro70z28; 07-04-2011 at 09:58 PM.

"PLAN" your life like you will live to 120.

"LIVE" your life like you could die tomorrow.

John 3:16

>>>>>>

188Likes

188Likes LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote

To the top

Where is everybody?