Thread: 32 ford truck project

Threaded View

-

05-16-2014 04:20 PM #11

Update*

Truck will be hauled back to my home garage on Sunday. The list above and then some has been knocked out. Now it is time to finish about 4-5 hours of small crap and then pulled apart to start on the paint process.

I see a few sharpie markers and a case of zip-lock bags in my future

Now for those that were interested in the process of the under dash brake pedal assembly. Below are a few pictures. Yes, it is way over built but we are dealing with one of the most important parts of the truck...Brakes.

It all started with paper and a pen. It saved me a good bit of material in the end.

Next I cut the base plate and side plates out of .250 plate and the pivot bolt is .625"

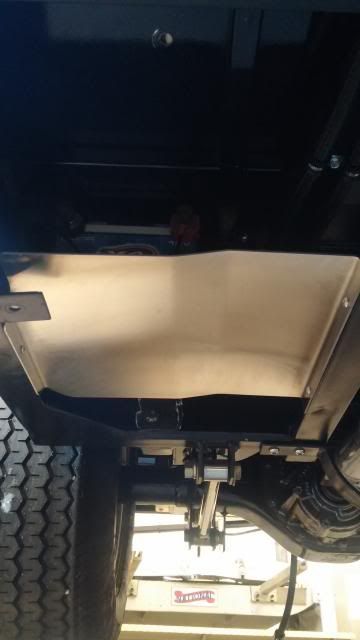

Test Fit

Pivot tube is 1" OD chromoly that is bored .750" for the .625" bronze bushings. I cut the master arm and pedal attachment out of .375". All welded up!

Final test fit. I'm waiting on my water jet guy to cut out the pedal arm that I drew in CAD earlier today.

The suggested pedal ratio from Wilwood was 5.5:1 for their 7/8" bore tandem master and their disc brakes. Final finished pedal ratio is 5.48:1 so I think I did ok. I also managed to keep the pedal at a decent resting height from the floor and the pedal does completely compress the master without contacting the floor. I have about .300" to accommodate for sound deadening and carpet.

DXF. File of the pedal

I also managed to get the brake lines made and the braided line tabs welded on the frame.

Stainless heat shields made and installed.

Throttle cable and pedal done (Pedal will be changing to a black version)

Inside A/C Lines and heater hoses are also done.

Bed to filler neck tube was also welded in. This will be ground down and welded several time to create a nice rounded edge. ( Dont mind the arch on the cap some idiot hit the pedal while the torch was laying in the bed... Yeah that would be me )

)

142Likes

142Likes LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote

time for a new forum to visit. when they sold sr.com it went down hill fast. no more forum just a cheap site selling junkie cars. the canadians killed hr.com. mods are real pricks. as with any site...

Where is everybody?