Thread: Bead rollers

-

08-12-2011 03:15 PM #16

Irish Diplomacy ..the ability to tell someone to go to Hell ,,So that they will look forward to to the trip

-

Advertising

- Google Adsense

- REGISTERED USERS DO NOT SEE THIS AD

-

08-12-2011 07:36 PM #17

Yeah, I'm finding that out Pat. I went to talk to a couple of local shops today and pretty much got the same answer.

Of course when I got home I found out a had a freeze plug leaking on the Caddy powered El Camino…….the rear one on the driver’s side head where there is only about 1” between the plug and fire wall. I’m stubborn and at least for now am refusing to pull the head to do a freeze plug. God I love cars.I've NEVER seen a car come from the factory that couldn't be improved.....

-

08-13-2011 10:23 AM #18

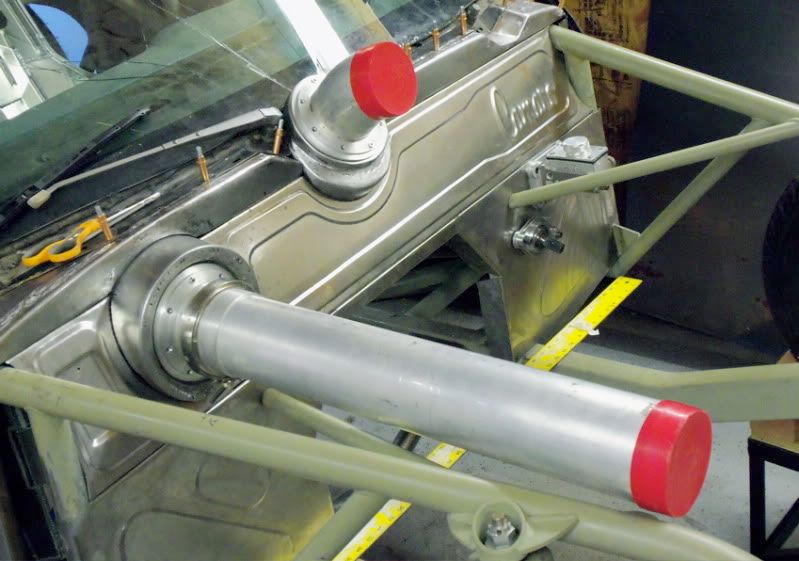

Don I like the open ended roller. When I was doing my floor patch panels, I couldn't find one that was wide enough from harbor freight. So I went to a metal welder I knew, brought him some cardboard templates, and he cut up the sheet metal and rolled the beads for about 50 bucks. Saved me time, and money for my inevitable mistakes. But that bead roller you have is very cool. It would be nice to have the space and the right tools for everything!"  "No matter where you go, there you are!" Steve.

"No matter where you go, there you are!" Steve.

-

08-13-2011 10:39 AM #19

Steve, it is one of those tools, like a sheet metal brake, that you might use one time in a year or two, but when you need it they sure come in handy and make the job nicer. Our brake and bead roller will be getting used pretty soon when we build the bed for my rpu, so the investment will pay off.

It seems like every new tool or piece of equipment a person buys becomes "How did I ever live without this !" If only I could afford a waterjet !

Don

-

08-13-2011 04:07 PM #20

Don,

Does the metal pull in when the bead is formed or does the metal just stretch? From the pics it doesn't look like the metal pulls in at all. If it doesn't pull in my I presume that the force of the non bead area of the upper and lower dies on the metal keeps it from stretching?

Jack.www.clubhotrod.com/forums/showthread.php?t=44081

-

08-13-2011 04:13 PM #21

The right size and placement of beads with a bead roller adds so much strength to the panel it's allowed me to use lighter material and get the same amount of support! The racer in me is always in favor of anything that will save weight without sacrificing strength.Yesterday is history, tomorrow is a mystery, Live for Today!

Carroll Shelby

Learning must be difficult for those who already know it all!!!!

-

08-13-2011 10:08 PM #22

Don - So right about the right tools. I remember lamenting about renting a cherry picker, and your advice to buy it because it would pay for itself! Great advice, and I am glad I listened! It comes in handy all the time."  "No matter where you go, there you are!" Steve.

"No matter where you go, there you are!" Steve.

-

08-14-2011 01:09 AM #23

Jack, it only distorts it ever so slightly, mainly the metal stretches to form the bead. Kinda the same thing as punching louvers, I would guess. The panels were still pretty much the same flatness after we were done.

Steve, yep, any tool you buy turns out that way. My engine lift is like yours, it sits for weeks or months unused, but when you need it the thing sure comes in handy. I'm glad that worked out good for you, purchasing one. For years I would run to the rental place and lay out $ 25 a day, then I got wise and bought one. The one I have now belonged to a good friend, and when he passed away his family told me to keep it. Every time I use it I think of him and what a good friend he was.

Don

-

08-14-2011 06:58 AM #24

I did the "Z" firewall with a harbor freight unit, but it needed some stiffening up. I replaced the hand crank with a bicycle wheel, that made it much easier to control.

Would multiple passes, increasing pressure each pass, work? You'd have to be dead on each pass, maybe not practical?

"PLAN" your life like you will live to 120.

"LIVE" your life like you could die tomorrow.

John 3:16

>>>>>>

-

08-14-2011 07:12 AM #25

Wow, that really looks great.............and TRICKY ! You are right about the double pass thing. It seems like the die gets slightly off track on the subsequent passes and you get distorted lines, no matter how careful you are.

You are right about the double pass thing. It seems like the die gets slightly off track on the subsequent passes and you get distorted lines, no matter how careful you are.

Don

4Likes

4Likes

LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote

".......So sanded it all down and resprayed. ......" Been there. done that on a couple of paint jobs over the years. Usually took me a couple of days to get over being mad before I started...

Stude M5 build