Thread: ford 302 motor mounts?

Hybrid View

-

12-26-2012 06:34 AM #1

ford 302 motor mounts?

snapped off both motormount bolts flush on my engine block.

currently designing/modifying mounts to be able to handle the downward stress and take the load off those bolts.

this will be the 4th try.

does anybody have a photo or two showing how they did it?

as always thanks!a hot rod is whatever i decide it is.

-

12-26-2012 07:03 AM #2

Billy,

The thread below, SBF Motor Mounts, shows my chassis mounts clearly, and also gives the PN for the associated OEM motor mount to link up with them. The chassis mount is a pre-fab unit from Pete & Jake's - http://www.peteandjakes.com/Catalog4.aspx?pid=548 and they work very well. Here's the link to my earlier post:

SBF Motor Mounts

If you want an alternative, here's a neat kit from Paul Horton that eliminates the OEM rubber mount altogether, replacing it with simple urethane bushings.

Ford Motor Mounts, Urethane Insulated » Welder Series Inc.Last edited by rspears; 12-26-2012 at 08:17 AM.

Roger

Enjoy the little things in life, and you may look back one day and realize that they were really the BIG things.

-

12-26-2012 08:50 AM #3

I'm left questioning what you're using for bolts Billy. Assuming that your motor has 2 bolts each side that fasten the mount to the block... Were they grade 8 or 5 or???

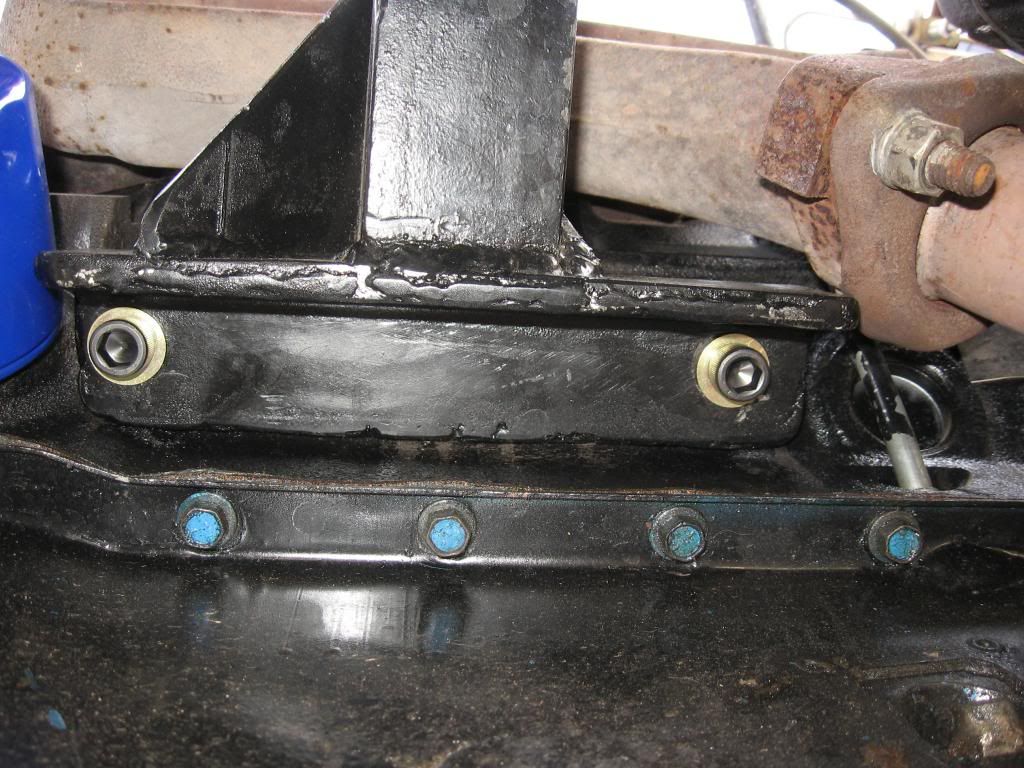

I used mounts for a "79" F-150 pickup, then a simple rectangular box from the frame of 3/8" flat stock with a angled end at the motor side, tack welded together with all parts in place \ mocked up. Then removed to bench for final welding. Then back into car for final assembly.

Because I had access to them from work, I used Bowman "Bowmalloy" bolts. They are like equal to a grade 10 or 12 or something crazy like that. I think the block would break before the bolts but at a minimum I would've used a grade 8 bolt.

I think the real secret is to do the mockup and fitment so that there are no undue stresses so that the mount only has to carry the motor weight and torsional force, any extra stress like twisting\bending because of poor fitment will surely shorten the fasteners lifespan.

-

12-26-2012 10:19 AM #4

I answered your post on Hotrodders.com: ford 302 motor mounts? - Hot Rod Forum : Hotrodders Bulletin BoardDave W

I am now gone from this forum for now - finally have pulled the plug

-

12-26-2012 10:48 AM #5

I'm confused How do you break bolts with downward force. I guess I'll stick to chevys.Charlie

Lovin' what I do and doing what I love

Some guys can fix broken NO ONE can fix STUPID

W8AMR

http://fishertrains94.webs.com/

Christian in training

-

12-26-2012 10:49 AM #6

That one's pretty easy. With the cantilever design of the mount the downward force (weight of the engine) imparts a moment, putting the bolt in tension to one side. Under hard acceleration that tension direction switches directions on the driver's side, and increases on the passenger side. Originally Posted by cffisher

Originally Posted by cffisher

I gotta agree with Mike, it sounds like maybe you've just got a bolt problem. I used Grade 8 bolts to bolt the mount to the block, and also as the through bolt for increased shear strength. How about some pictures of the mounts you're using now?Last edited by rspears; 12-26-2012 at 10:55 AM.

Roger

Enjoy the little things in life, and you may look back one day and realize that they were really the BIG things.

-

12-26-2012 02:41 PM #7

Generally issues when bolts are broken off flush with the hole is that the bolts are bottomed out in the hole and overtorqued trying to tighten them---already happened to this guy 4 times

-

12-26-2012 05:28 PM #8

You could be 100% on this one, Jerry! A bolt a bit too long is going to bottom out, leaving some "slop" for the mount to rock back & forth on acceleration, eventually snapping the head off the bolt. How about it Billy? Did you thread the bolts in w/o the mount to check the length?Roger

Enjoy the little things in life, and you may look back one day and realize that they were really the BIG things.

-

12-26-2012 06:14 PM #9

here all the time i use nails on ford s if a nice one wood screws

Irish Diplomacy ..the ability to tell someone to go to Hell ,,So that they will look forward to to the trip

-

12-26-2012 06:24 PM #10

It only takes 3/8 bolts on a chev and ford needs bigger ones--------

-

12-26-2012 11:00 PM #11

Last edited by pat mccarthy; 12-27-2012 at 06:23 AM.

Irish Diplomacy ..the ability to tell someone to go to Hell ,,So that they will look forward to to the trip

-

12-27-2012 03:37 AM #12

My 302 uses 4, 3/8" bolts..... mount to block.

-

12-27-2012 06:01 AM #13

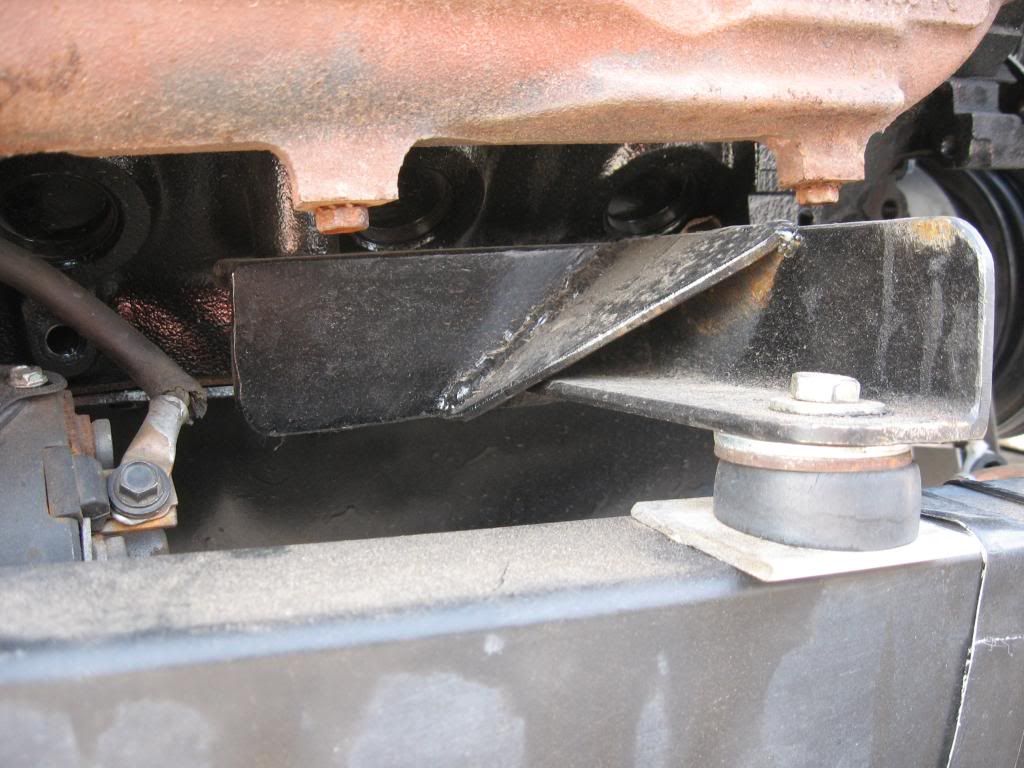

the earlier failures were the steel itself cracking/splitting.

yes i measured the holes for depth.

i replaced the bolts with hex heads that are supposed to be a bit stronger than grade 8's

the photos will show why the previous bolts failed.

they couldnt stand up to the leverage.

Last edited by billy zz; 12-27-2012 at 06:05 AM.

a hot rod is whatever i decide it is.

-

12-27-2012 08:07 AM #14

Thanks for the pics Billy----that is a bad design on the mounts and the only way you will stop the breakage is to turn those two steel mounts into a crossmember by running a tube down and under the pan from one side to the other--

As you have it you probably have a 20to1 leverage on the bolts plus in addition to the engine weight throw in the torque from the engine plus twist of chassis----your lucky the bolts broke instead of pulling the side of the block/waterjacket open----------

you could also shorten them and weld a mount to the inside of your frame rail so the mounts didn't have so much leverage against the bolts

-

12-27-2012 08:33 AM #15

Gotta agree, that design just doesn't work - way too much moment arm applying torque to the bolts. If I were you I'd order either the Pete & Jake's or the Paul Horton Kit and get that support point out much closer to the engine with some healthy chassis mounts welded solid. You could also copy their design approach and cut the pieces out of some healthy plate steel yourself if you want to invest more time than money, and if you have the equipment to cut the heavy stuff. Both web sites have drawings & pics to show the details, and the Paul Horton site even has a welding video to walk through the assembly process. You also need to be sure that your boxing plate is good & strong where you weld the chassis mounts in place.Last edited by rspears; 12-27-2012 at 08:38 AM.

Roger

Enjoy the little things in life, and you may look back one day and realize that they were really the BIG things.

2Likes

2Likes

LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks Reply With Quote

Reply With Quote

time for a new forum to visit. when they sold sr.com it went down hill fast. no more forum just a cheap site selling junkie cars. the canadians killed hr.com. mods are real pricks. as with any site...

Where is everybody?